Camellia oleifera shell powder additive and preparation method thereof

A technology of camellia oleifera husk and husk powder, which is applied in the direction of adhesive additives, non-polymer adhesive additives, flat products, etc. It can solve the problems of aldehyde glue, isocyanate adhesive sticking boards, etc., and improve water resistance properties, and the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

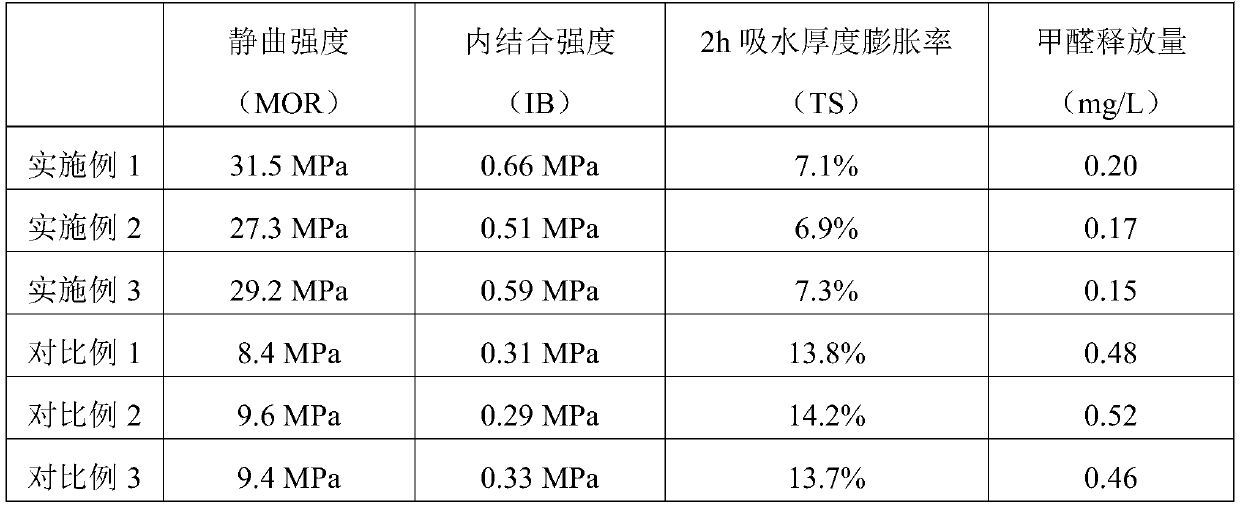

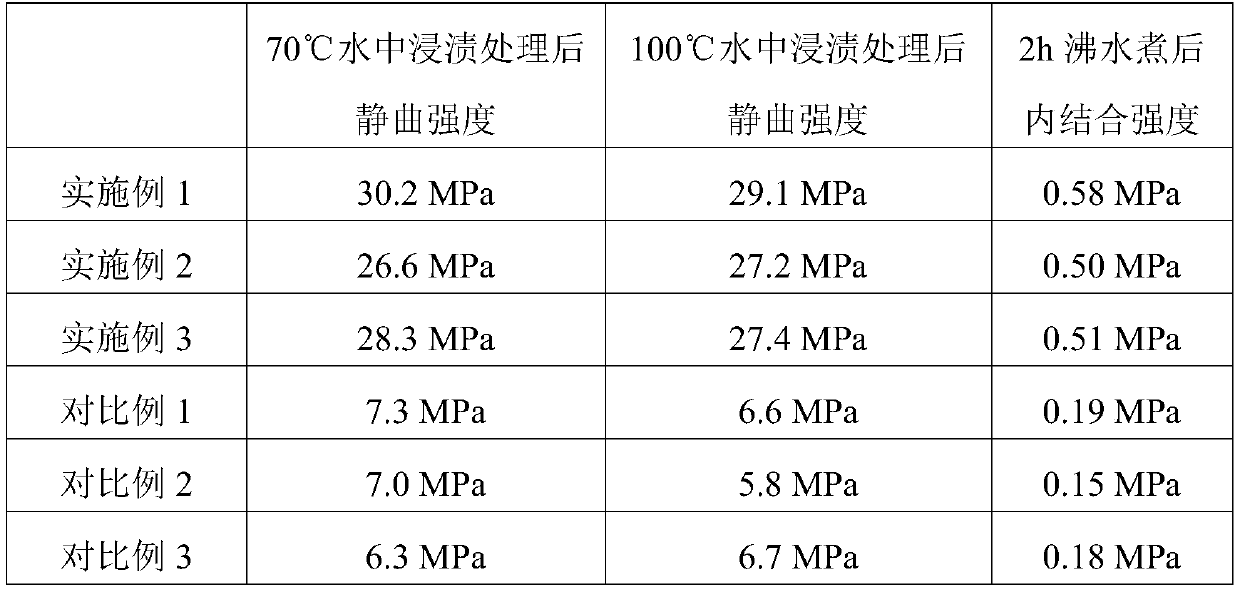

Examples

specific Embodiment approach 1

[0037] Specific embodiment one: the present embodiment camellia oleifera shell powder additive comprises modified camellia oleifera shell powder and modified nano-montmorillonite, and the quality of the modified nano-montmorillonite is 0.5% to 0.5% of the quality of modified camellia oleifera shell powder 1%.

specific Embodiment approach 2

[0038] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the preparation method of the modified camellia oleifera shell powder comprises the following steps:

[0039] ①Crush the camellia oleifera shell and pass through a 40-60 mesh sieve to obtain camellia oleifera shell powder, add 0.5-1.5mol / L NaOH solution and epichlorohydrin into the camellia oleifera shell powder, and then stir at 50-60°C Modified for 30 to 60 minutes, then washed the camellia oleifera shell powder with deionized water until neutral, and dried at 65 to 80°C for 3 to 5 hours to obtain a modified camellia oleifera shell powder;

[0040] The mass ratio of camellia oleifera shell powder to NaOH solution is 1g: (10-25) mL, and the volume ratio of camellia oleifera shell powder to epichlorohydrin is 1 g: (1-8) mL;

[0041] ② Add hyperbranched polyamide solids and deionized water to the primary modified Camellia oleifera shell powder, then stir at 25-30°C for 30-60 m...

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment is different from Embodiment 2 in that: the hyperbranched polyamide is an aliphatic hyperbranched polyamide, an aromatic hyperbranched polyamide or aliphatic and aromatic mixed hyperbranched polyamide. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com