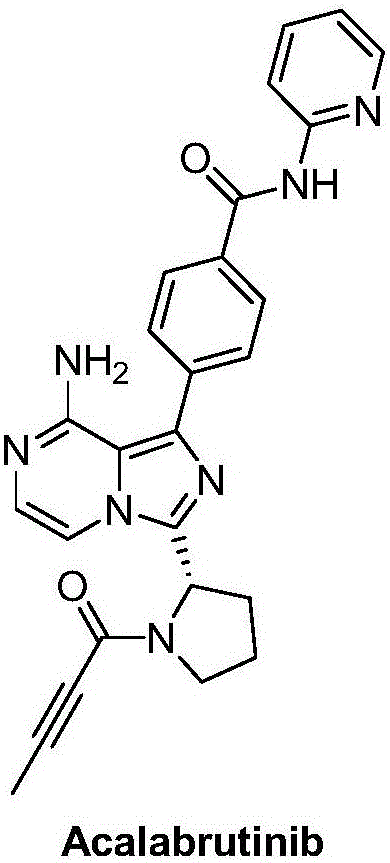

Synthesis method of BTK inhibitor Acalabrutinib for treating chronic lymphocytic leukemia

A technology of lymphocytes and synthetic methods, applied in the field of medicinal chemical synthesis, can solve problems such as complex and cumbersome operations, unfavorable scale-up production and industrial promotion, and many impurities, and achieve the effects of simplified process flow, simplified operation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

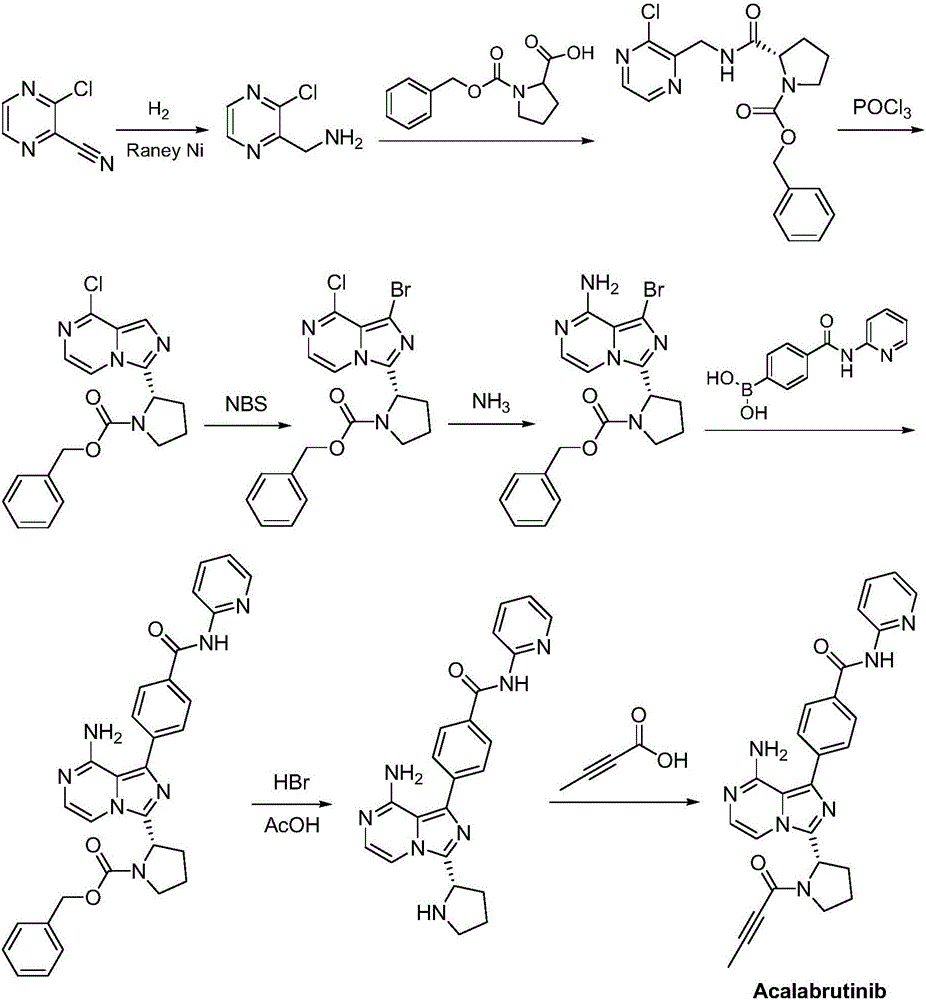

Method used

Image

Examples

Embodiment 1

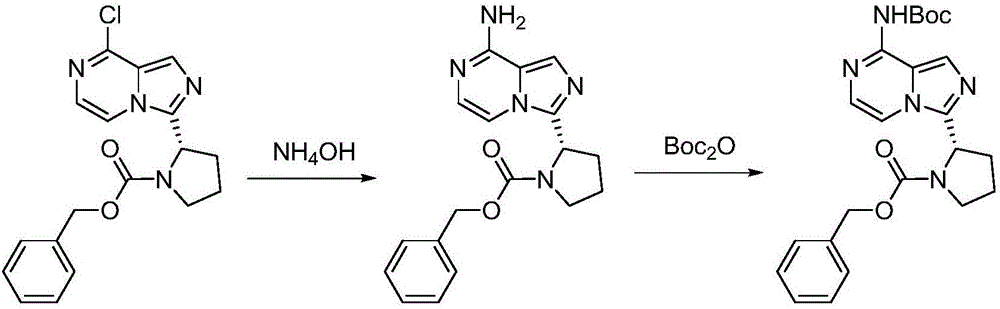

[0030] (1) Preparation of benzyl (S)-2-(8-aminoimidazo[1,5-a]pyrazin-3-yl)-1-pyrrolidinecarboxylate:

[0031] (S)-Benzyl 2-(8-chloroimidazo[1,5-a]pyrazin-3-yl)-1-pyrrolidinecarboxylate (10 g, 28 mmol) was dissolved in N-methylpyrrolidone (80 mL), Add ammonia water (168mmol) with a concentration of 28% by mass, and place the reaction mixture in a closed stainless steel reactor at 85°C and 2.5 atmospheric pressure to react for 6 hours. After the reaction is completed, cool to 40°C and release the pressure of the system, and slowly add water (50mL), cooled to 10°C, crystallized for 3h, filtered, and recrystallized from isopropanol to obtain (S)-2-(8-aminoimidazo[1,5-a]pyrazin-3-yl)-1 -benzyl pyrrolidinecarboxylate, off-white solid (8.5g), yield 90%, the reaction formula of this step is as follows:

[0032]

[0033] (2) Preparation of (S)-2-(8-tert-butoxycarbonylaminoimidazo[1,5-a]pyrazin-3-yl)-1-pyrrolidinecarboxylic acid benzyl ester:

[0034] (S)-2-(8-Aminoimidazo[1,5-a]py...

Embodiment 2

[0052] (1) Preparation of benzyl (S)-2-(8-aminoimidazo[1,5-a]pyrazin-3-yl)-1-pyrrolidinecarboxylate:

[0053] (S)-Benzyl 2-(8-chloroimidazo[1,5-a]pyrazin-3-yl)-1-pyrrolidinecarboxylate (15 g, 42 mmol) was dissolved in N-methylpyrrolidone (75 mL), Add ammonia water (273mmol) with a concentration of 28% by mass, and place the reaction mixture in a closed stainless steel reactor at 70°C and a pressure of 3 atmospheres to react for 8 hours. After the reaction is completed, cool to 40°C and release the pressure of the system, and slowly add water (50mL), cooled to 10°C, crystallized for 3h, filtered, and recrystallized from isopropanol to obtain (S)-2-(8-aminoimidazo[1,5-a]pyrazin-3-yl)-1 -benzyl pyrrolidinecarboxylate, off-white solid (12.9g), yield 91%, the reaction formula of this step is the same as that of Example 1.

[0054] (2) Preparation of (S)-2-(8-tert-butoxycarbonylaminoimidazo[1,5-a]pyrazin-3-yl)-1-pyrrolidinecarboxylic acid benzyl ester:

[0055] (S)-Benzyl 2-(8-ami...

Embodiment 3

[0067] (1) Preparation of benzyl (S)-2-(8-aminoimidazo[1,5-a]pyrazin-3-yl)-1-pyrrolidinecarboxylate:

[0068] (S)-Benzyl 2-(8-chloroimidazo[1,5-a]pyrazin-3-yl)-1-pyrrolidinecarboxylate (4.5g, 12.6mmol) was dissolved in N-methylpyrrolidone (70mL ), adding ammonia water (69.4mmol) with a concentration of 28% by mass percentage, the reaction mixture was placed in a closed stainless steel reactor and stirred for 4 hours at 90°C and 2 atmospheric pressure, and after the reaction was completed, it was cooled to 35°C and the system pressure was released. Slowly add water (50mL), cool to 10°C, crystallize for 3h, filter, and recrystallize from isopropanol to obtain (S)-2-(8-aminoimidazo[1,5-a]pyrazin-3-yl )-benzyl 1-pyrrolidinecarboxylate, off-white solid (3.9g), yield 92%, the reaction formula of this step is the same as that of Example 1.

[0069] (2) Preparation of (S)-2-(8-tert-butoxycarbonylaminoimidazo[1,5-a]pyrazin-3-yl)-1-pyrrolidinecarboxylic acid benzyl ester:

[0070] (S)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com