Novel tall oil asphalt emulsifier and preparation method thereof

A technology of tall oil asphalt and emulsifier, which is used in building components, building insulation materials, buildings, etc., can solve the problems of increased dosage, poor reusability, poor storage stability effect, etc., and achieves strong reusability. , excellent emulsifying performance, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

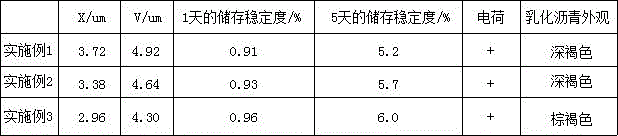

Examples

Embodiment 1

[0020] A novel tall oil asphalt emulsifier, composed of 20-25 parts by weight of tall oil, 10-12 parts by weight of a mixture of halogenated hexadecane and octadecane, hexadecane oxide and epoxy 10-12 parts by weight of octadecane mixture, 15-20 parts by weight of polyethylene polyamine, 5-10 parts by weight of epichlorohydrin, 5-10 parts by weight of trimethylamine dodecyl alcohol, 5-8 parts by weight of ethylenediamine part, auxiliary agent 3-8 parts by weight.

[0021] The tall oil includes fatty acid and fatty alcohol, and the composition weight ratio is 7:3.

[0022] The composition weight ratio of hexadecane oxide and octadecane oxide in the mixture of hexadecane oxide and octadecane oxide is 3:7-7:3, preferably 6:4.

[0023] The polyethylene polyamines include diethylenetriamine, triethylenetetramine and tetraethylenepentamine, and the composition weight ratio is: diethylenetriamine: triethylenetetramine: tetraethylenepentamine=3:5:2.

[0024] Described auxiliary agen...

Embodiment 2

[0031] A kind of preparation method of novel tall oil pitch emulsifier comprises the following steps:

[0032] S1. Add 25 parts by weight of tall oil, 25 parts by weight of polyethylene polyamine and 8 parts by weight of additives into a three-necked reaction bottle, and add 0.5 mol / L toluene as a water-carrying agent according to the ratio of material to liquid at 1:3. , heated to 140°C, refluxed for 4 hours, after complete reaction, toluene was distilled off;

[0033] S2. Add 95% ethanol to the three-necked reaction flask according to the ratio of material to liquid at 1:5, heat up to 40°C, add 10 parts by weight of epichlorohydrin and react for 3 hours, and heat to 80°C, add 10 parts by weight of Trimethylamine dodecyl alcohol was reacted for 6h, and ethanol was distilled out after the reaction was complete;

[0034] S3. Add 10 parts by weight of a mixture of hexadecane halide and octadecane, 10 parts by weight of a mixture of hexadecane oxide and octadecane oxide, and 5 p...

Embodiment 3

[0037] S1. Add 25 parts by weight of tall oil, 25 parts by weight of polyethylene polyamine and 8 parts by weight of additives into a three-necked reaction bottle, and add 1.0mol / L toluene as water-carrying agent according to the ratio of material to liquid at 1:4. , heated to 130°C, refluxed for 5 hours, after complete reaction, toluene was distilled off;

[0038] S2. Add 85% ethanol to the three-necked reaction flask according to the ratio of material to liquid at 1:6, heat up to 40°C, add 10 parts by weight of epichlorohydrin and react for 3 hours, and heat to 80°C, add 10 parts by weight of Trimethylamine dodecyl alcohol was reacted for 6h, and ethanol was distilled out after the reaction was complete;

[0039] S3. Add 12 parts by weight of a mixture of hexadecane halide and octadecane, 12 parts by weight of a mixture of hexadecane oxide and octadecane oxide, and 8 parts by weight of ethylenediamine, heat to 100 ° C, and react for 4 hours , after the reaction is complete,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com