Method and device for recycling C4 by-product obtained in gasoline production

A production device and by-product technology, which is applied in the field of C4 by-product recycling devices obtained from gasoline production, can solve problems that affect the acquisition of gasoline production devices, cannot obtain sufficient reaction, reduce the actual conversion rate of raw materials, etc., and achieve reduction in processing costs, The effect of reducing energy consumption and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

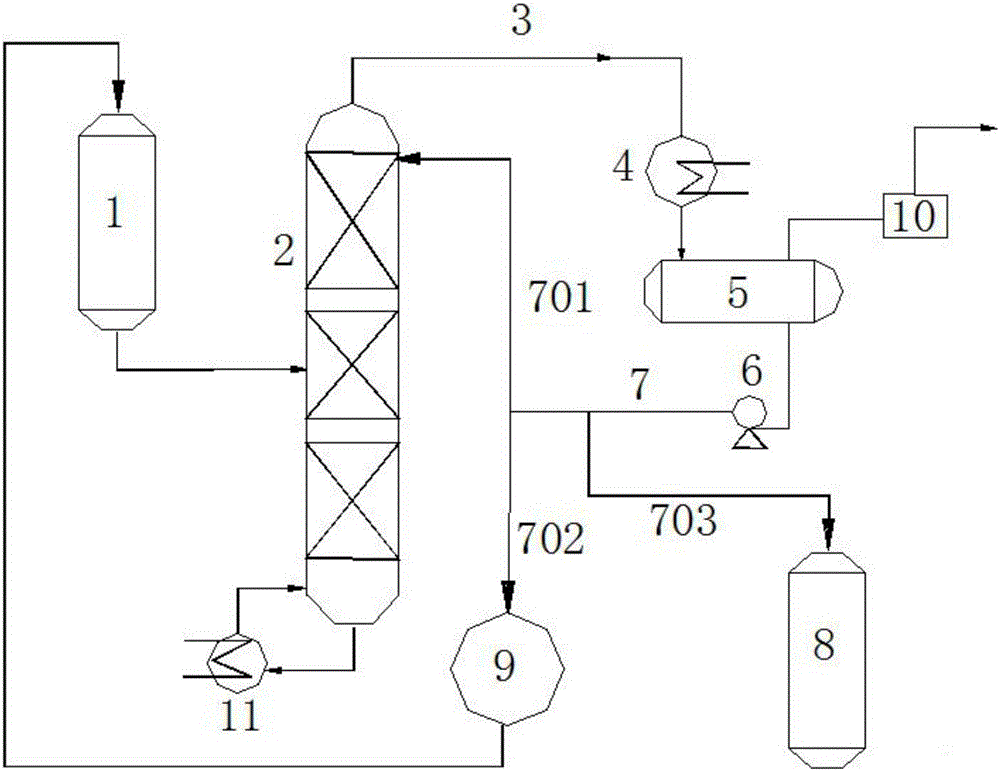

[0026] Reference figure 1 , A device for recycling C4 by-products from gasoline production, including gasoline production device 1 and stabilization tower 2. The bottom end of stabilization tower 2 is equipped with a reboiler 11 to provide heat to stabilization tower 2; The top is equipped with a bleed air pipe 3, the end of the bleed pipe 3 is connected to the input end of the water cooler 4, the output end of the water cooler 4 is connected to the input end of the reflux tank 5 through a pipe, and the output end of the reflux tank 5 is provided with a return pipe 7, The reflux pipe 7 is provided with a reflux pump 6, and the reflux tank 5 is also connected to the cold box 10.

[0027] The return pipe 7 is divided into return branch pipe A 701, return branch pipe B 702, return branch pipe C 703, return branch pipe A 701 is connected to stabilization tower 2, return branch pipe B 702 is connected to the input end of C4 storage tank 9, and the output end of C4 storage tank 9 is co...

Embodiment 2

[0029] A method for reusing C4 by-products from gasoline production, the method steps are as follows:

[0030] S1: The C1-C12 by-products produced by the gasoline production device are separated into the stabilization tower. The temperature of the gasoline production device is 390°C and the pressure is 0.7MPa;

[0031] S2: C1-C4 by-products are output from the bleed air pipe at the top of the stabilization tower and enter the water cooler;

[0032] S3: The C1-C3 by-products output from the water cooler enter the cold box in a gaseous state, and the C4 by-products enter the return pipeline in a liquid state;

[0033] S4: The C4 by-products entering the reflux pipeline are respectively transported to the aromatization reaction device, C4 storage tank and stabilization tower for recycling, where the temperature of the aromatization reaction device is 490°C and the pressure is 0.5MPa.

Embodiment 3

[0035] A method for reusing C4 by-products from gasoline production, the method steps are as follows:

[0036] S1: The C1-C12 by-products produced by the gasoline production unit are separated into the stabilization tower. The temperature of the gasoline production unit is 420°C and the pressure is 0.7MPa;

[0037] S2: C1-C4 by-products are output from the bleed air pipe at the top of the stabilization tower and enter the water cooler;

[0038] S3: The C1-C3 by-products output from the water cooler enter the cold box in a gaseous state, and the C4 by-products enter the return pipeline in a liquid state;

[0039] S4: The C4 by-products entering the reflux pipeline are respectively transported to the aromatization reaction device, C4 storage tank and stabilization tower for recycling, wherein the temperature of the aromatization reaction device is 530°C and the pressure is 0.5MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com