Method and System for Non-Uniform Catalyst Heating for Internal Combustion Engine

A uniform heating and catalytic converter technology, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problem of insufficient purification of engine exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses.

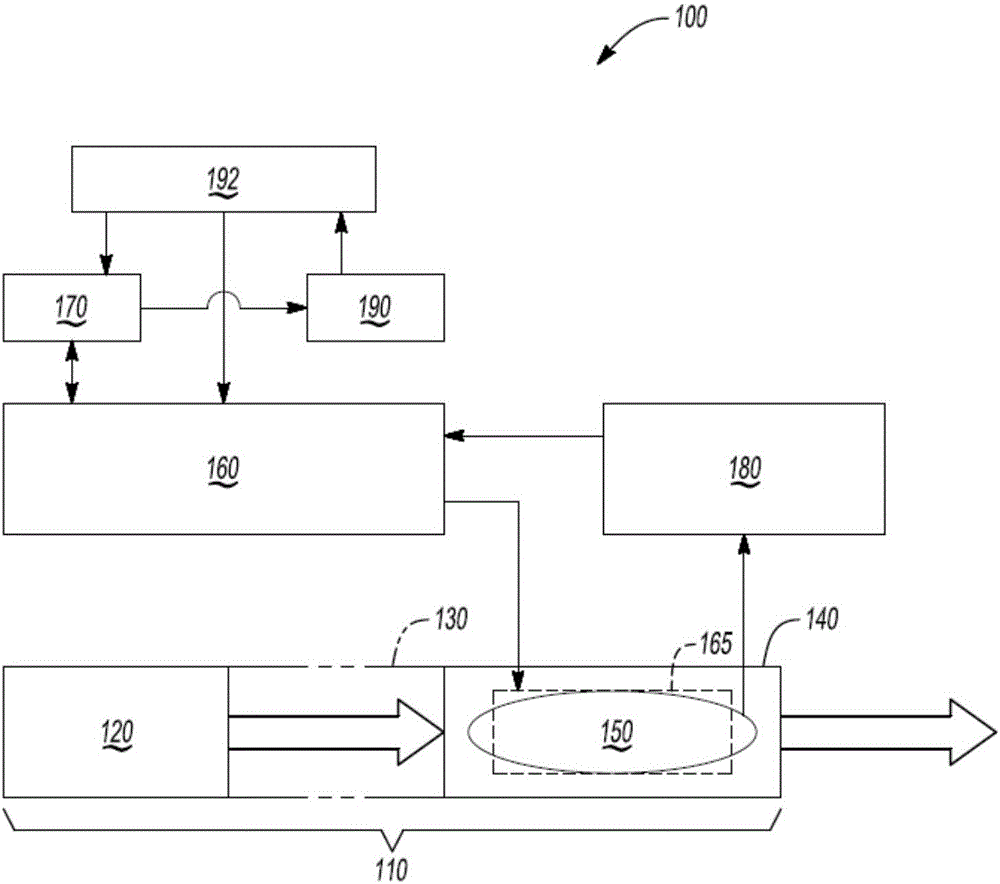

[0038] figure 1 An illustration of a schematic diagram of a heated catalytic converter system 100 for heating a catalyst when the catalyst is below a predetermined light-off temperature is provided in accordance with an exemplary embodiment; it should be understood that a catalytic converter according to an exemplary embodiment may Utilized to reduce pollutants in exhaust gases produced by all types of engines burning gasoline, diesel or alternative fuels as fuel. For example, catalytic converters according to exemplary embodiments may be utilized to reduce emissions from passenger cars, commercial and recreational vehicles, agricultural vehicles and machines, lawn mowers, snowplows, generators, and other outdoor machines and equipment.

[0039] System 100 includes exhaust passage 110 configured to receive exhaust from an engine exhaust manifold 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com