Low temperature pump

A cryopump, low temperature technology, applied in pumps, pump components, variable capacity pump components, etc., can solve the problems of limiting the adsorption limit of cryopumps, gas adsorption, poor condensation effect, etc., and achieve optimized adsorption/condensation limit, optimized adsorption /Condensing efficiency, the effect of structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

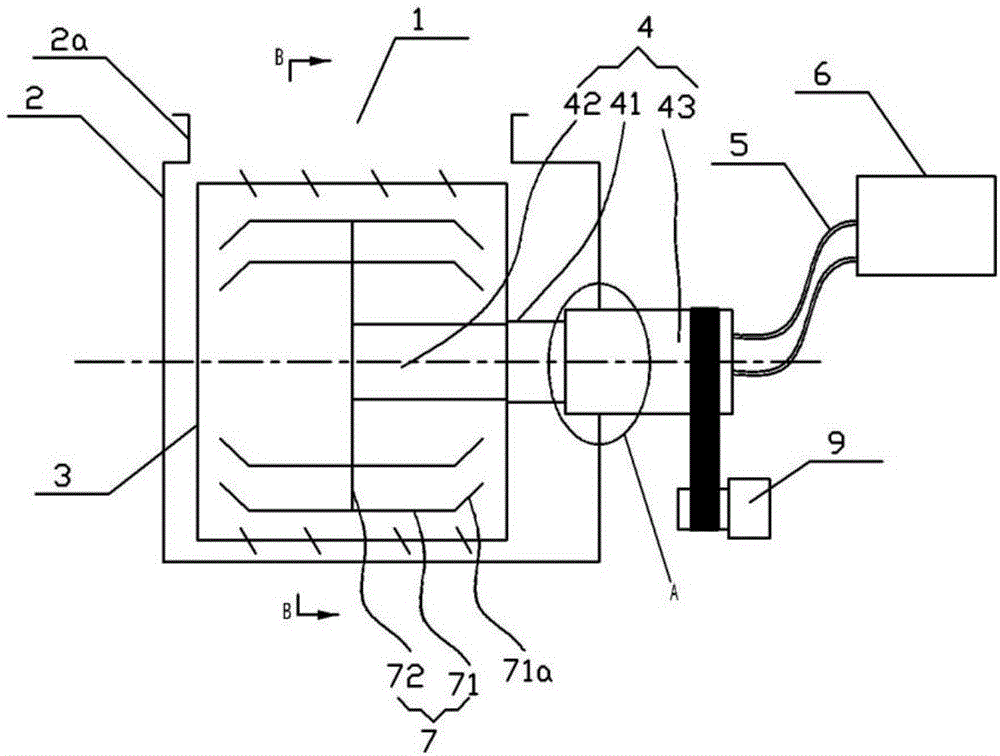

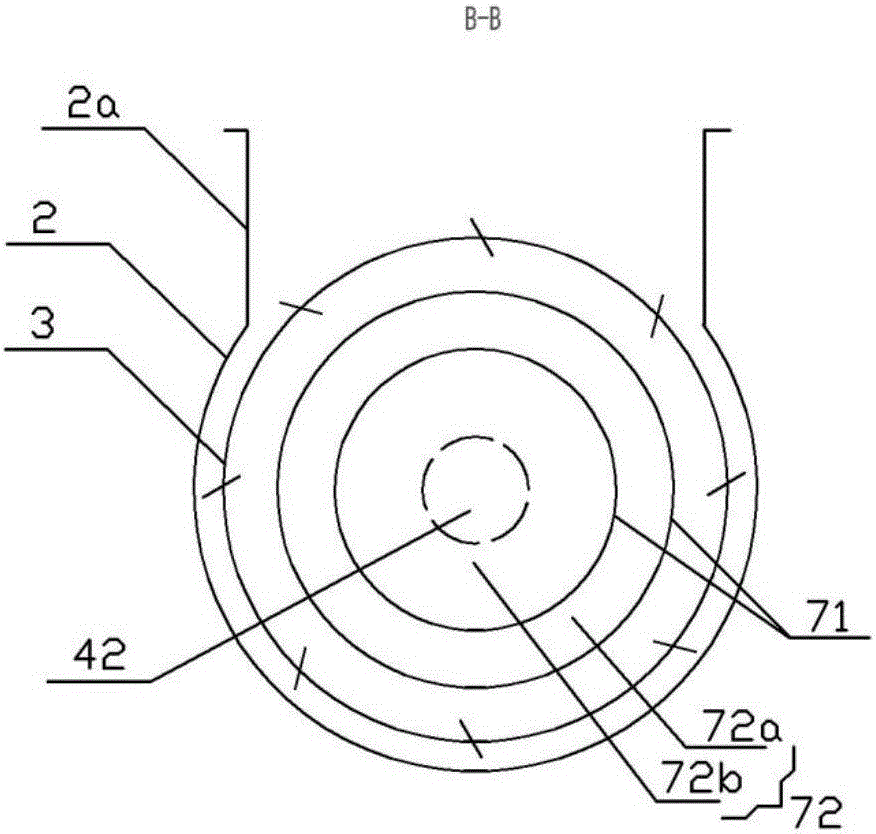

[0023] Such as Figure 1 to Figure 3 As shown, the cryopump is installed in the vacuum chamber for raising the vacuum degree in the vacuum chamber to a desired level. The cryopump has a suction port 1 for receiving gas from the vacuum chamber. The cryopump includes a housing 2 , a radiation cold shield 3 , a low-temperature cold source, and a cryopanel assembly 7 .

[0024] The shell 2 of the cryopump is roughly cylindrical with cover plates at both ends, and its axis is coaxial with the cold head of the low-temperature cold source. An opening 2a connected to the vacuum cavity (ie, the suction port of the cryopump) is provided on the side of the casing 2 . The opening is also cylindrical and extends outward in the radial direction of the cryopump, and the top end of the opening has a flange structure. The opening is preferably in the shape of a square tube.

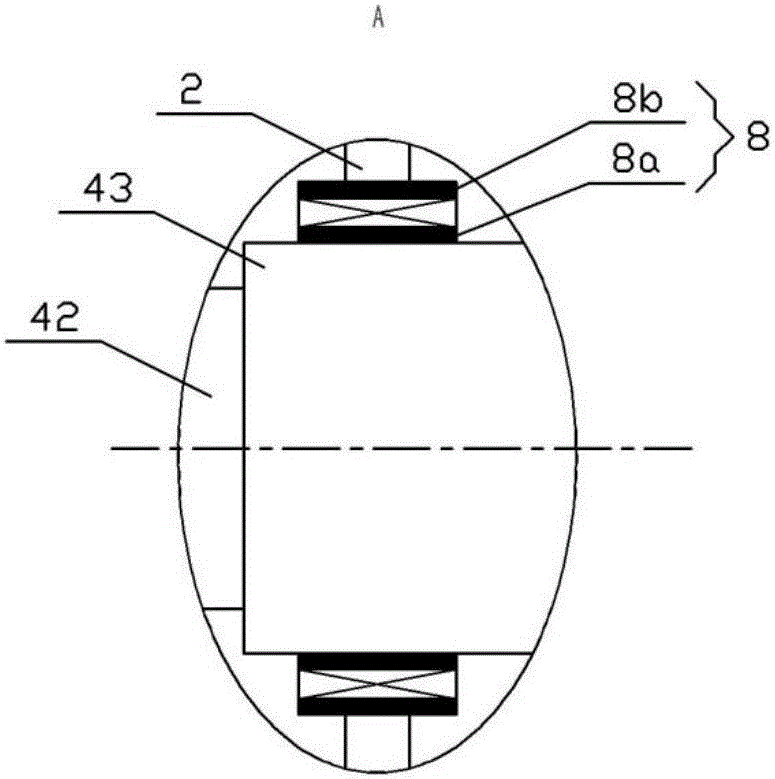

[0025] The low-temperature cold source is a two-stage GM refrigerator, which includes a helium compressor 6 and a c...

Embodiment 2

[0032]Embodiment 2 is roughly the same as Embodiment 1 in structure composition and connection mode of the cryopump. The difference is that the cryopanel assembly 7 is improved on the basis of the first embodiment, and the cryopanel assembly 7 includes a cryogenic cylinder 71 and a cryogenic vane 73 . The cryogenic cylinder 71 is nested and installed on the secondary cooling platform and is thermally connected with it. There are a plurality of low-temperature blades 73 , which are thermally connected and installed on the surface of the low-temperature cylinder 71 , and are arranged at certain intervals in the circumferential and longitudinal directions of the outer surface of the low-temperature cylinder 73 . As mentioned above, the larger the angle between the direction of the gas inlet and the plane of the low-temperature vane (that is, the closer to the vertical angle direction), the better the condensation and adsorption effect of the low-temperature vane. If the cryogeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com