Efficient fused road coating mixing device

A mixing device and road technology, applied in mixers, mixing methods, fluid mixers, etc., can solve the problems of uneven mixing and low utilization rate of powder materials, and achieve improved mixing uniformity, high utilization rate of powder materials, high utilization rate of powder materials, etc. The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

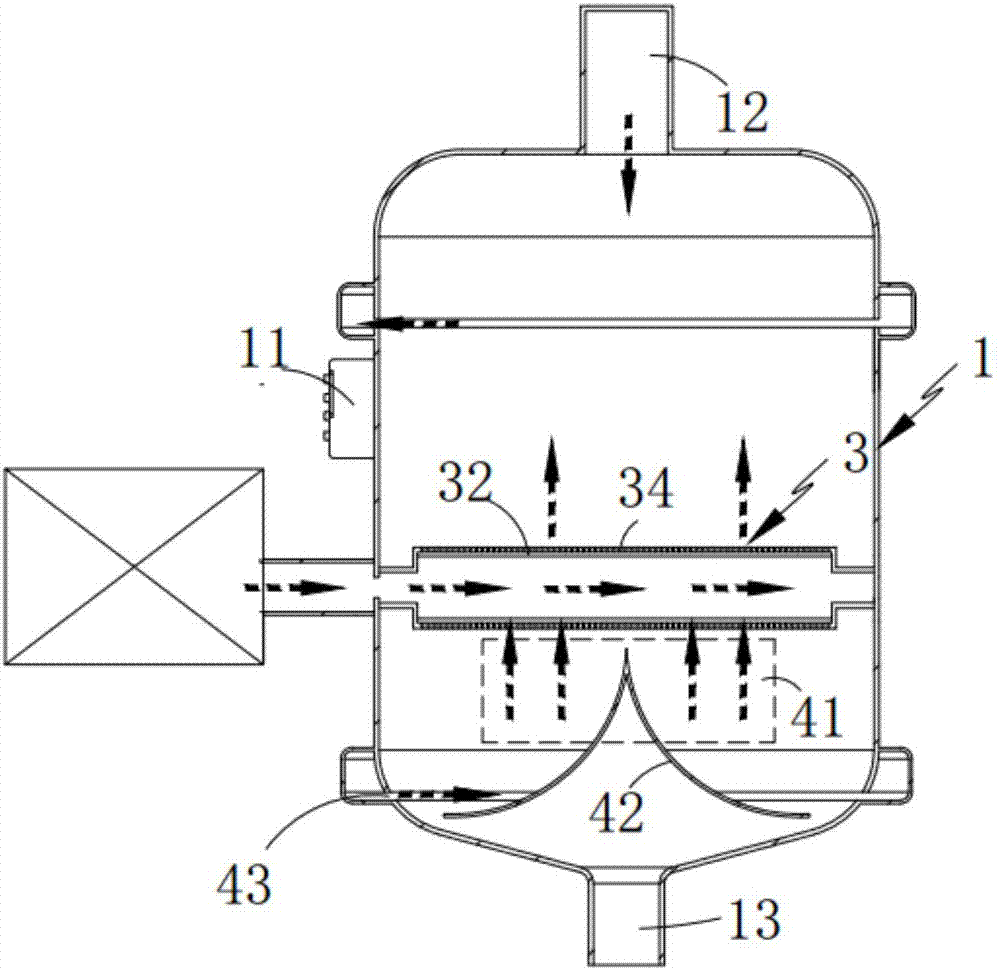

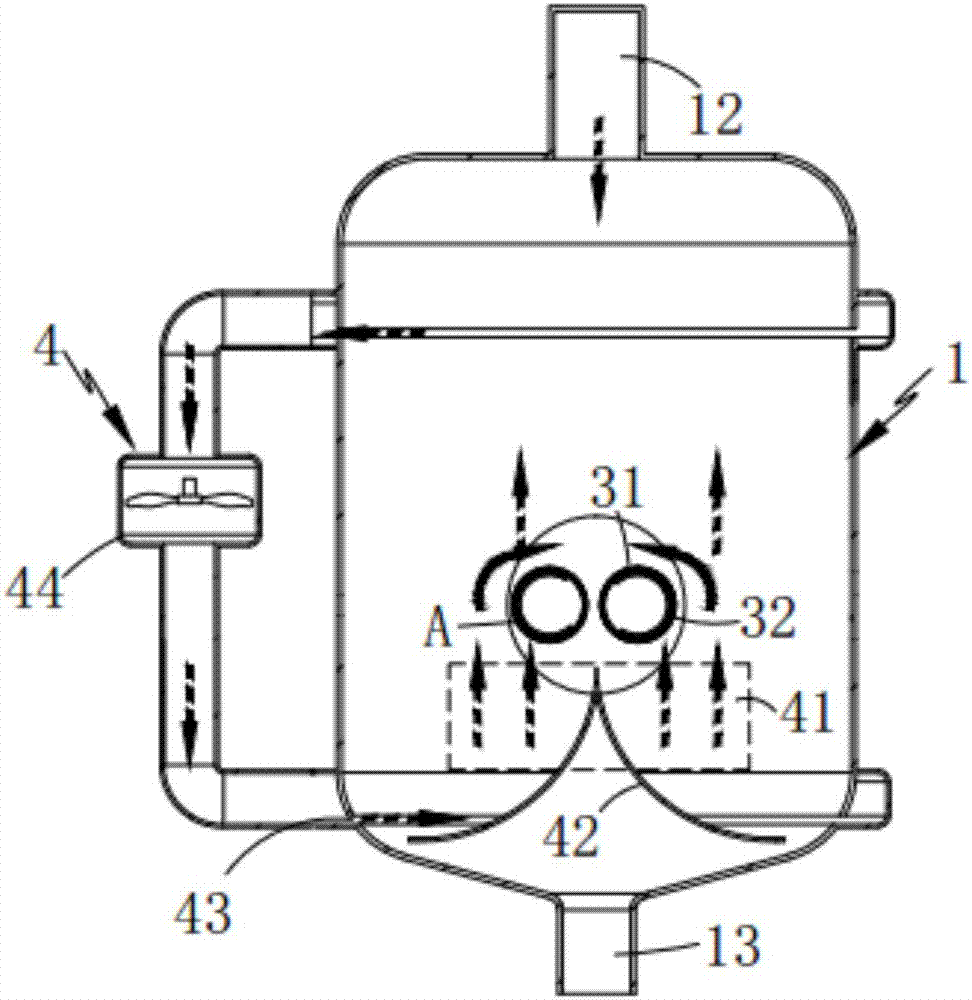

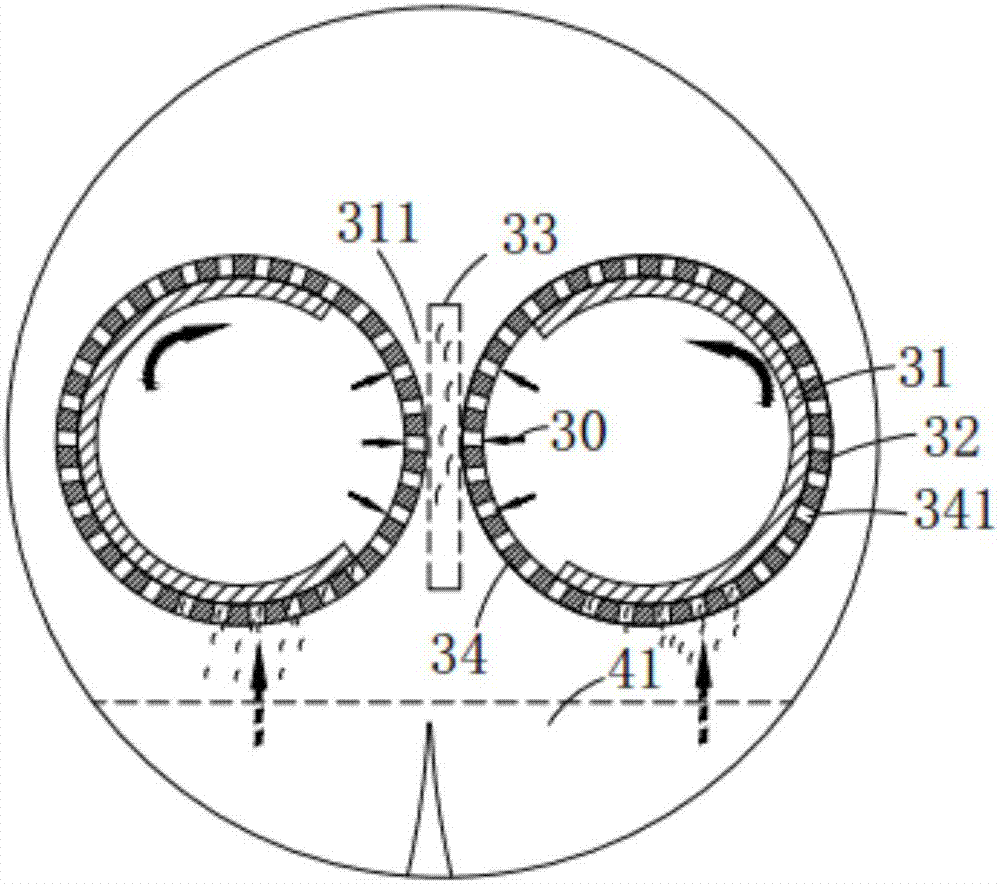

[0030] Such as figure 1 , 2 Shown in and 3, a kind of high-efficiency melting road paint mixing device, comprises melting chamber 1, also comprises:

[0031] Mixing assembly 3, the mixing assembly 3 is arranged in the melting chamber 1, the mixing assembly 3 is provided with an air injection part 34 communicating with its interior, and the gas-powder mixture inside the mixing assembly 3 is sprayed out through the air injection part 34 to form a directional Powder flow 30, the directional powder flow 30 is initially mixed with the powder during the liquid resin transmission process;

[0032] The powder blowing assembly 4, the mixed scattered powder is lifted by the powder blowing assembly 4 and then mixed with the initially mixed resin.

[0033] It should be noted that the mixing assembly 3 is a rotating roller 32 with a number of powder conveying holes 341 on the outer peripheral surface, and the gas-powder mixture in the interior is continuously sprayed out from the air inj...

Embodiment 2

[0041] Such as figure 1 , 2, 3 and 4, wherein the same or corresponding parts as in the second embodiment adopt the corresponding reference numerals with the second embodiment, for the sake of simplicity, only the difference between the second embodiment and the second embodiment is described below; the third embodiment and the implementation The difference of Example 2 is that the powder blowing port 43 is set intermittently.

[0042] It should be noted that, in this embodiment, the air flow for the flying treatment of the scattered filler falling on the blanking plate 42 is introduced from the upper part of the melting chamber 1 through the air flow generator 44, so that the inside of the mixing chamber 41 forms a lower and The upper gas flow direction, thereby reducing the falling speed of the scattered fillers, increasing the contact rate between the resin solution and the fillers, and at the same time ensuring a constant temperature in the melting chamber 1, thereby redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com