Circular saw

A circular saw, disc-shaped technology, applied in the field of circular saws with surface roughness, can solve the problems that the suppression of cutting vibration cannot be eliminated, and the finished surface cannot be ensured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

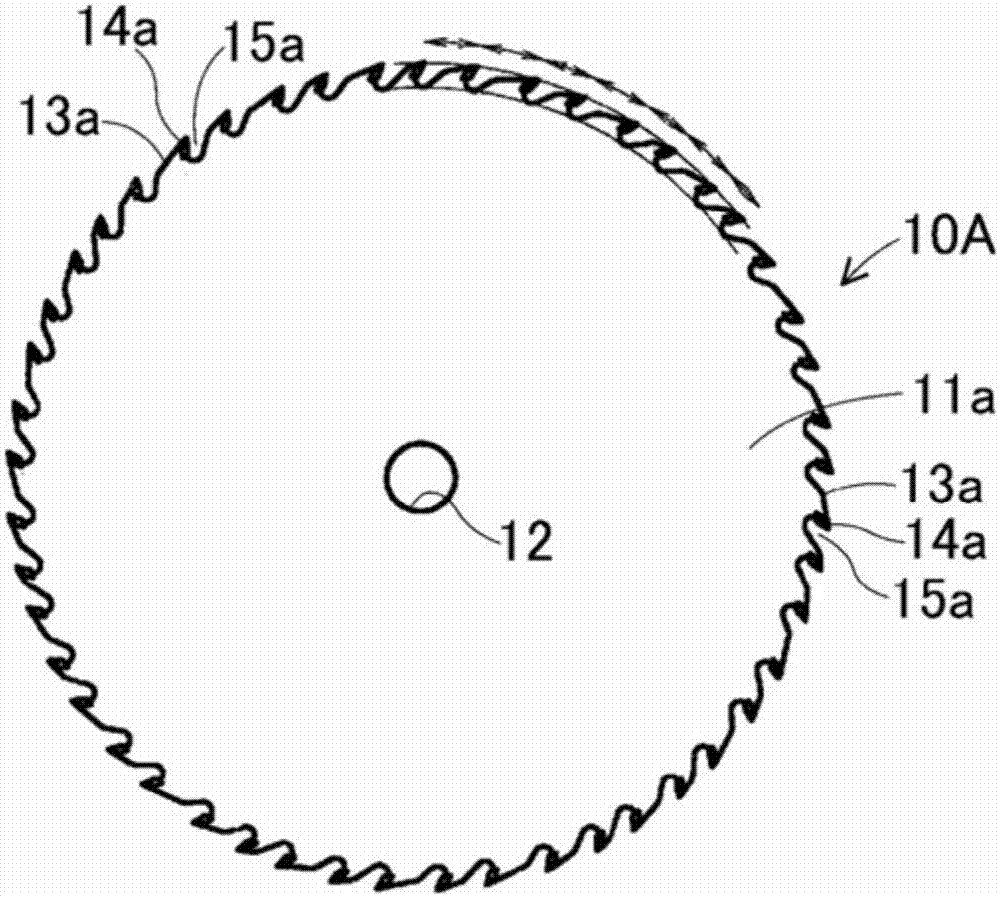

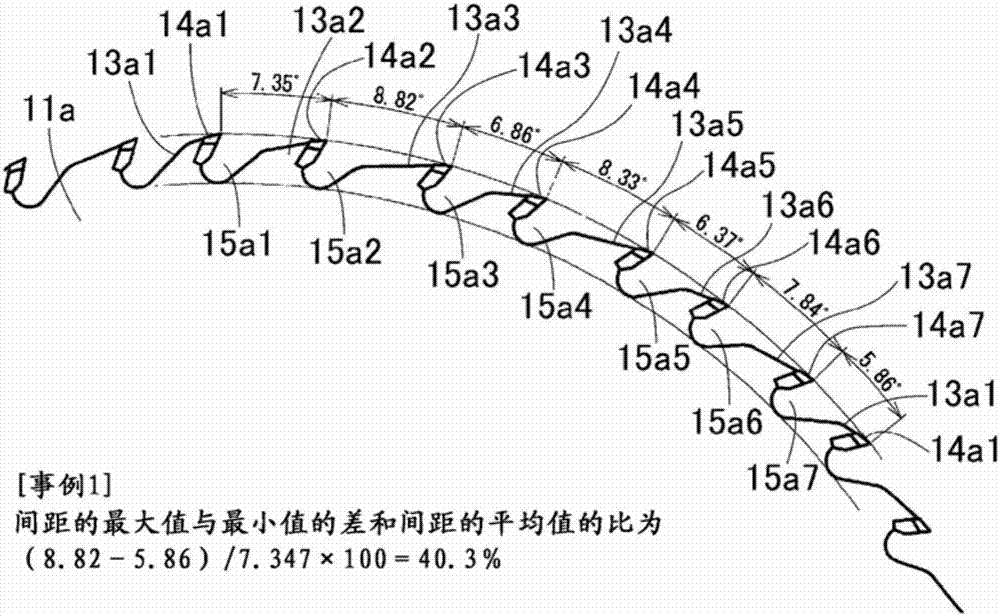

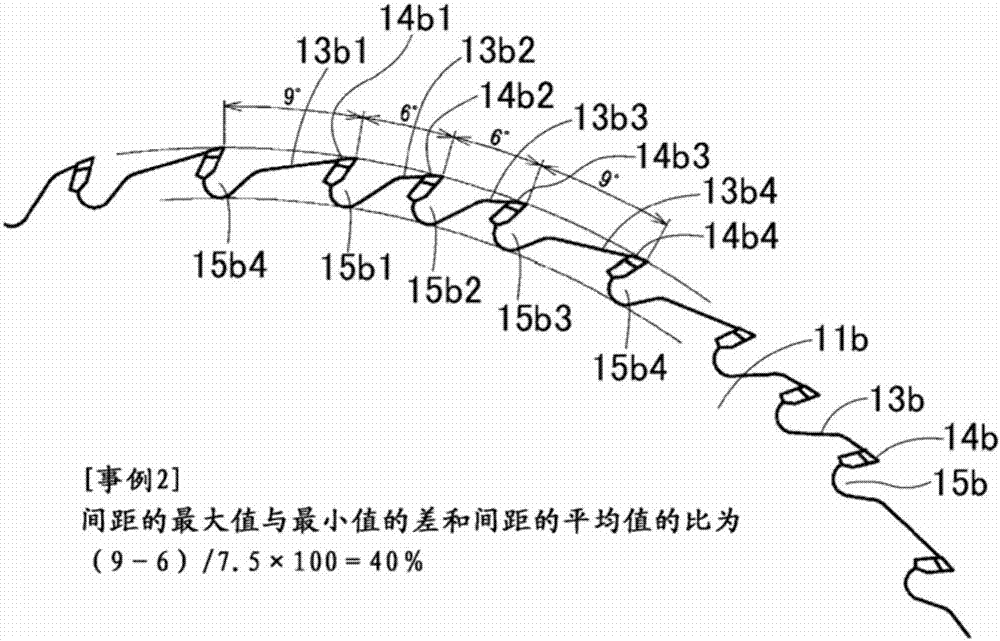

[0036] Embodiments of the present invention will be described below using the drawings. Figure 8 The circular saw 20 according to Example 1 is shown by an overall view. The base metal 21 constituting the circular saw 20 is a steel disk-shaped thin plate with an outer diameter of 305 mm×a tooth thickness of 2.8 mm, and a center hole 22 into which a rotating shaft of a machine to be processed is inserted is provided at the center thereof. The outer peripheral side of the base metal 21 forms approximately diamond-shaped blades 23 protruding in the radial direction at 72 positions in the circumferential direction, and each blade 23 is notched in an arc shape to form tooth chambers 24 recessed in the radial direction. On the front end side of each blade 23 in the rotation direction R, a mounting seat 25 for mounting a cutting tooth 28 is provided such that the cutout is substantially at a right angle.

[0037] Each blade 23 consists of three adjacent blades 23a, 23b, and 23c as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com