Method used for preparing high temperature resistant filter cloth from mineral fiber

A mineral fiber and filter cloth technology, applied in the field of filter cloth, can solve the problems of rising production cost, inability to withstand high temperature environment, short service life of filter cloth, etc., to reduce working pressure difference, improve filtration efficiency, excellent environmental corrosion resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

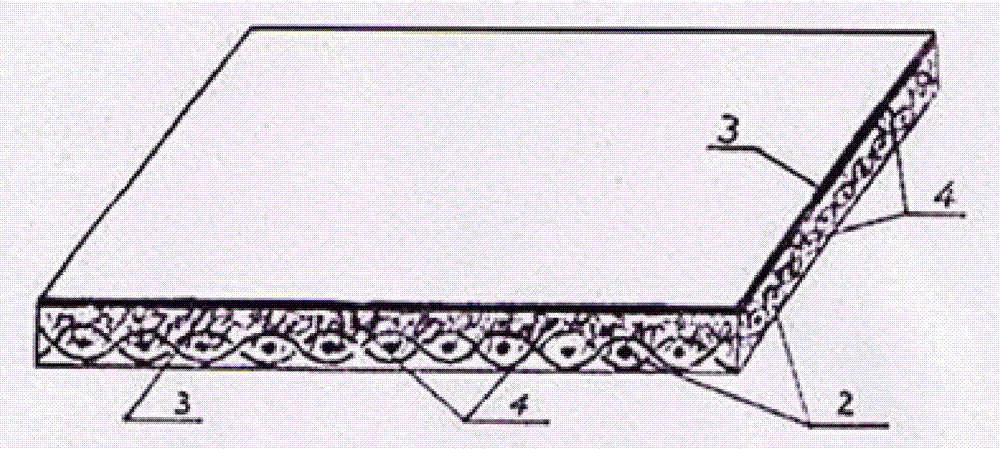

[0017] The embodiments of the present invention are described in detail below, and examples of the embodiments are attached. figure 1 with 2 Shown in. The embodiments described below with reference to the accompanying drawings are exemplary, and are only used to explain the present invention, and cannot be construed as limiting the present invention.

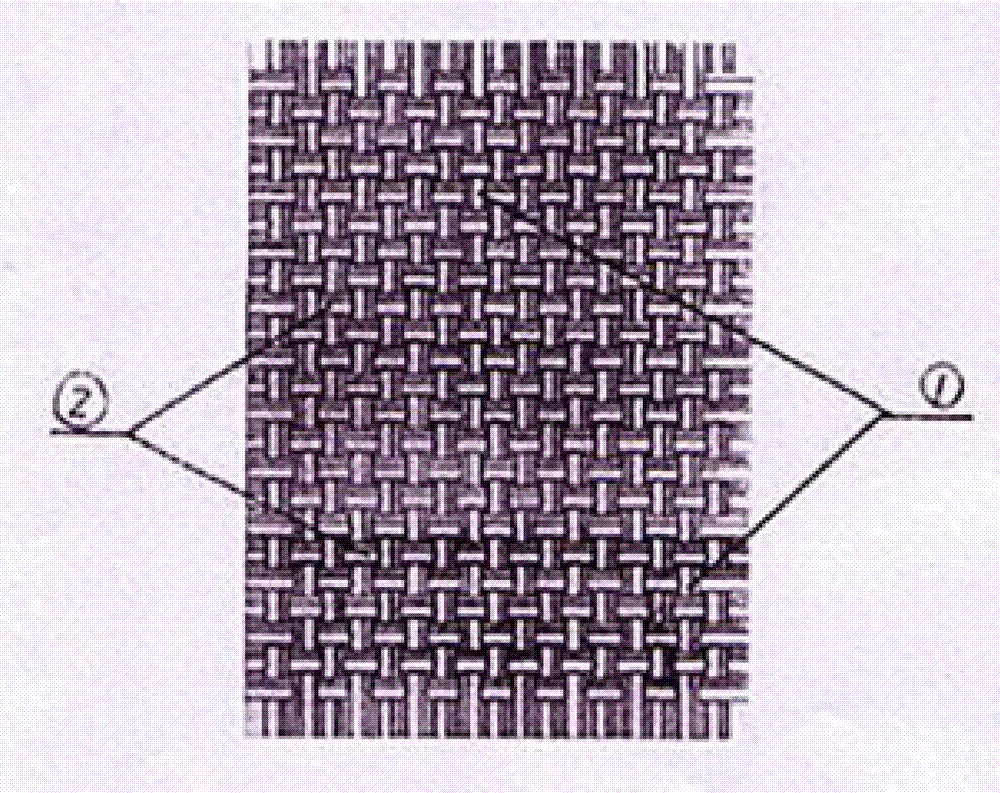

[0018] In the present invention, a high-temperature resistant fiber non-woven filter cloth based on monofilament woven mesh is provided. The filter cloth consists of a two-layer structure, namely: a base cloth layer 2 and a filter layer 4 (attached figure 1 in). The base fabric layer is a woven net structure made of chemical fiber monofilament materials with warp and weft interwoven. This kind of warp and weft interlaced woven mesh base cloth layer only plays the role of support and reinforcement, so the density of the warp and weft interlaced is as small as possible under the premise of ensuring the role of support and reinforceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com