Range extended double-motor electromechanical coupling system for vehicle and control method thereof

A dual-motor, extended-program technology, applied in the arrangement of multiple different prime movers of general power plants, motor vehicles, vehicle components, etc., can solve the problems of reduced efficiency and NVH performance, complex mechanical structure, and large layout size. Achieve the effect of reducing the cost of the vehicle, ensuring the power of the vehicle, and reducing the demand for battery pack capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

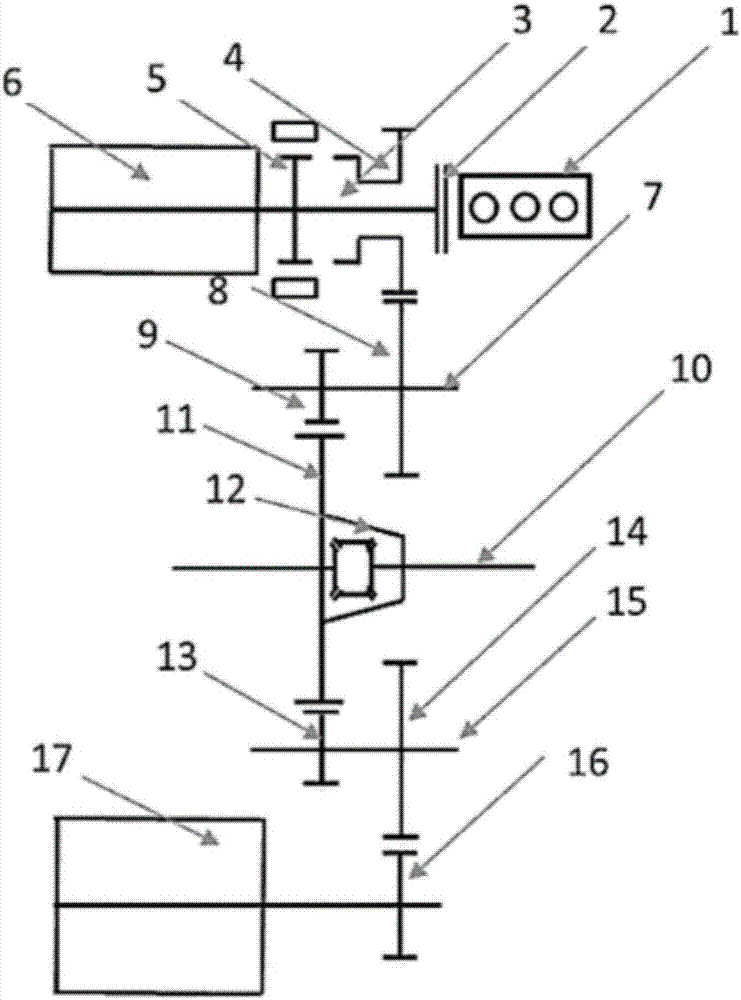

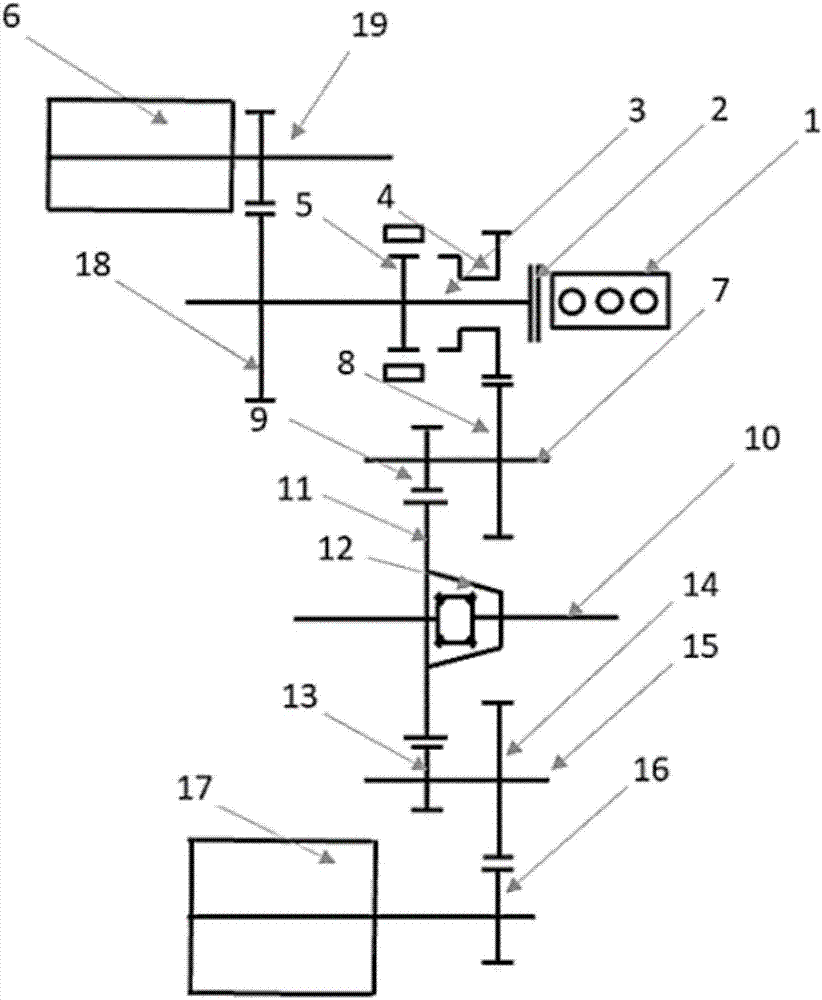

[0034] Such as figure 1 , figure 1As shown, this embodiment includes: engine 1, clutch 2, hybrid input shaft 3, hybrid input gear 4, synchronizer 5, second drive motor 6, hybrid intermediate shaft assembly 7, hybrid output gear 8 , hybrid intermediate shaft gear 9, main reduction drive axle assembly 10, main reduction gear 11, differential assembly 12, pure electric intermediate shaft gear 13, pure electric output gear 14, pure electric intermediate shaft assembly 15, pure electric The electric input shaft gear 16 and the first drive motor 17, wherein: the engine 1 is connected with the hybrid input shaft 3 through the clutch 2, the synchronizer 5 is fixed on the hybrid input shaft 3 through a spline, and the hybrid input gear 4 is connected by a needle roller The bearing is empty sleeved on the hybrid input shaft 3, and the hybrid input gear 4 is welded with coupling teeth. The second drive motor 6 is connected to the other end of the hybrid input shaft 3 through a spline. ...

Embodiment 2

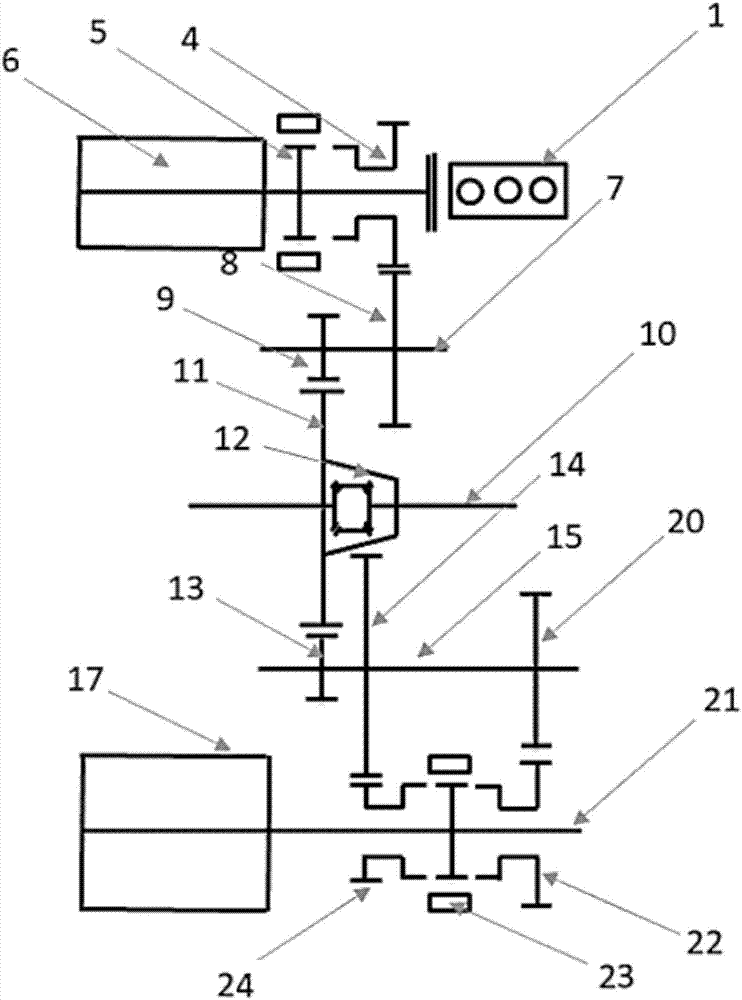

[0069] Such as image 3 As shown, since the whole vehicle is working, the first drive motor is always in working condition. In Embodiment 1, due to the fixed speed ratio of the transmission shaft system, it is impossible to take into account the high-efficiency performance range of the first drive motor, the maximum vehicle speed and the climbing performance of the vehicle. Therefore, in this embodiment, the power transmission mechanism of the first drive motor is replaced by a pure electric input gear assembly 22 for electric input second gear, a pure electric input gear assembly synchronizer 23, and a shaft gear 24 for pure electric input first gear. The input gear assembly 21 corresponds to adding a pure electric output second gear shaft gear 20 on the pure electric intermediate shaft assembly. When the vehicle is running at low speed, a large speed ratio is used to ensure high torque output. When the vehicle is running at a medium and high speed, a small speed ratio is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com