Closed substrate loading and unloading system for coating machine

A closed, coating machine technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of high labor intensity of workers, uneven product quality, and contaminated substrates, to avoid contamination, reduce contamination, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0018] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

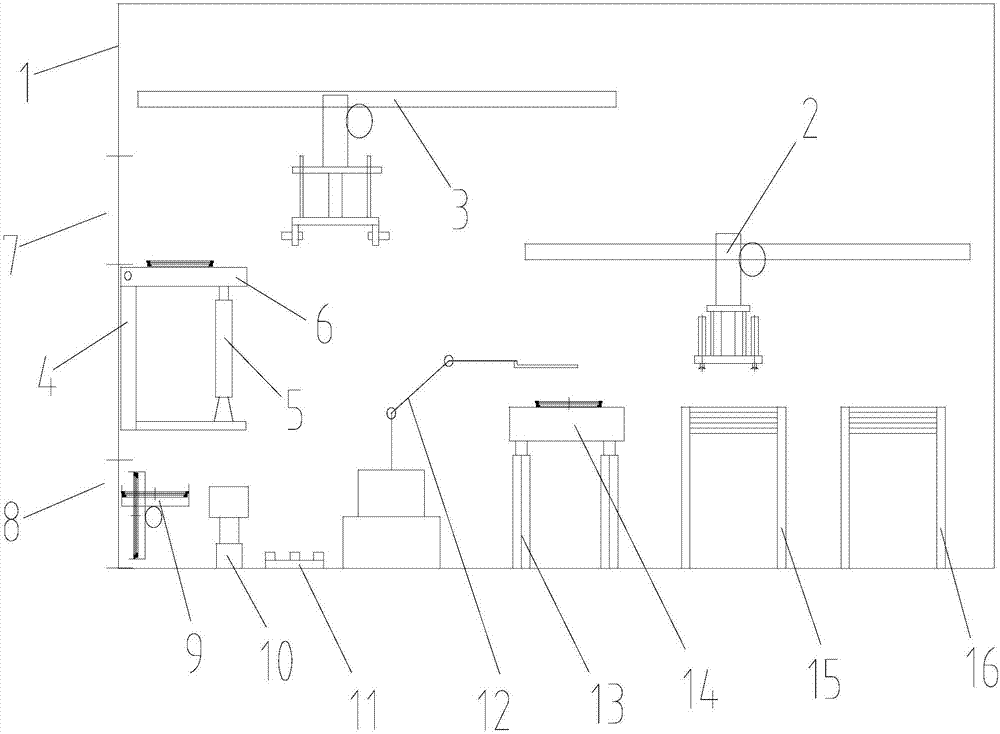

[0019] 1 is the shell, 2 is the substrate transfer mechanism, 3 is the clamp transfer mechanism, 4 is the discharge mechanism, 5 is the jacking cylinder, 6 is the discharge table, 7 is the discharge port, 8 is the feed port, 9 is a feeding mechanism, 10 is a substrate identification mechanism, 11 is a circle identification mechanism, 12 is a manipulator, 13 is a telescopic cylinder, 14 is a receiving frame, 15 is a square substrate storage rack, and 16 is a circular substrate storage rack.

[0020] For the convenience of description, the up, down, left, and right directions mentioned below are the same as figure 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com