Preparation method of lithium sulfate concentrated purification liquid in process of producing battery-grade lithium carbonate

A technology of concentration and purification, lithium sulfate, applied in lithium sulfate/sulfite, lithium carbonate;/acid carbonate and other directions, can solve the problem of high energy consumption, low energy consumption, lithium sulfate concentration and purification of impurities Low content and other problems, to achieve the effect of low process energy consumption and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

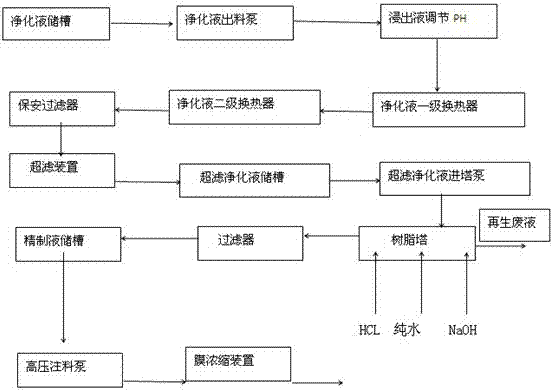

[0025] 1. The purification solution for impurity removal and purification meets the following indicators for storage. T=85℃ pH=11~12 SS=17PPmT.H=310mg / l Li 2 SO 4 9%

[0026] 2. The purification solution enters the resin tower process pH value regulator, adding sulfuric acid to adjust the pH value index is:

[0027] T=87℃ pH=9.5~10.5 SS=18PPm T.H=310mg / l Li 2 SO 4 9%

[0028] 3. After passing through the two-stage heat exchanger, the cooling index is: T=43°C, pH=9.5~10.5 SS=18PPm T.H=310mg / l Li 2 SO 4 9%

[0029] 4. The indicators of the security filter entering the membrane filtration system are: T=43°C, pH=9.5~10.5 SS=15PPm T.H=310mg / l Li 2 SO 4 9%

[0030] 5. The indicators for the purified liquid to enter the ultrafiltration device are: T=43°C, pH=9.5~10.5 SS=1PPm T.H=310mg / l Li 2 SO 4 9%

[0031] 6. The purified liquid is transported by the tower pump to the purified liquid and enters the chelating resin tower system for ion adsorption, and the resin fil...

Embodiment 2

[0034] 1. The purification solution for impurity removal and purification meets the following indicators for storage. T=87℃ pH=11~12 SS=16PPmT.H=305mg / l Li 2 SO 4 10%

[0035] 2. The purification solution enters the resin tower process pH value regulator, adding sulfuric acid to adjust the pH value index is:

[0036] T=87℃ pH=9.5~10.5 SS=17PPm T.H=305mg / l Li 2 SO 4 10%

[0037]3. After passing through the two-stage heat exchanger, the cooling index is: T=45°C, pH=9.5~10.5 SS=18PPm T.H=310mg / l Li 2 SO 4 10%

[0038] 4. The index of the security filter entering the membrane filtration system is: T=45°C, pH=9.5~10.5 SS=12PPm T.H=305mg / l Li 2 SO 4 10%

[0039] 5. The indicators for the purified liquid to enter the ultrafiltration device are: T=45°C, pH=9.5~10.5 SS=0.8PPm T.H=305mg / l Li 2 SO 4 10%

[0040] 6. The purified liquid is transported to the chelating resin tower system through the tower pump for ion adsorption, and the resin filling volume is 0.7m 3 Res...

specific Embodiment approach 3

[0042] 1. The purification solution for impurity removal and purification meets the following indicators for storage. T=86℃ pH=11~12 SS=15PPmT.H=300mg / l Li 2 SO 4 11%

[0043] 2. The purified liquid enters the resin tower process PH value regulator, adding sulfuric acid to adjust the PH value index is:

[0044] T=86℃ pH=9.5~10.5 SS=16PPm T.H=300mg / l Li 2 SO 4 11%

[0045] 3. After passing through the two-stage heat exchanger, the cooling index is: T=40℃, pH=9.5~10.5 SS=16PPm T.H=300mg / l Li 2 SO 4 11%

[0046] 4. The indicators of the security filter entering the membrane filtration system are: T=40°C, pH=9.5~10.5 SS=10PPm T.H=300mg / l Li 2 SO 4 11%

[0047] 5. The indicators for the purified liquid to enter the ultrafiltration device are: T=40°C, pH=9.5~10.5 SS=0.5PPm T.H=300mg / l Li 2 SO 4 11%

[0048] 6. The purified liquid is transported to the chelating resin tower system through the tower pump for ion adsorption, and the resin filling volume is 0.8m 3 Resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com