Chemically foamed polysulfide sealant for aerospace fuel tank use

一种聚硫化物、密封剂的技术,应用在其他化学过程、化学仪器和方法、胶粘剂等方向,能够解决微结构易塌陷或破裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

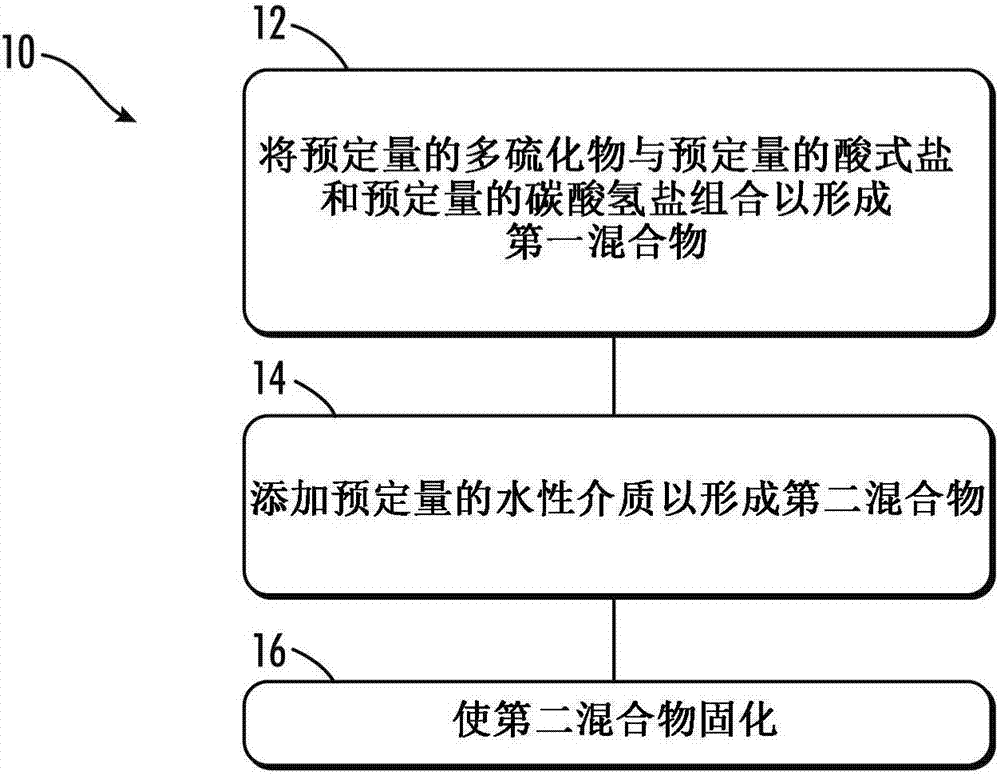

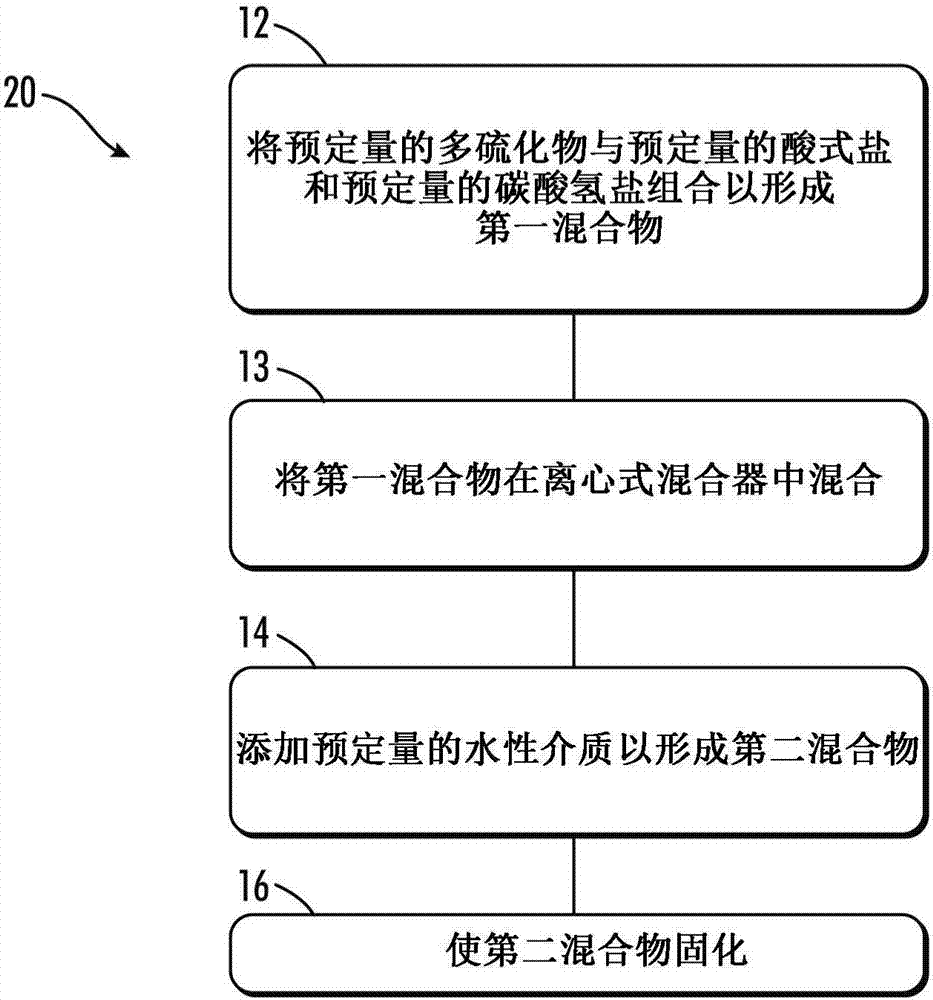

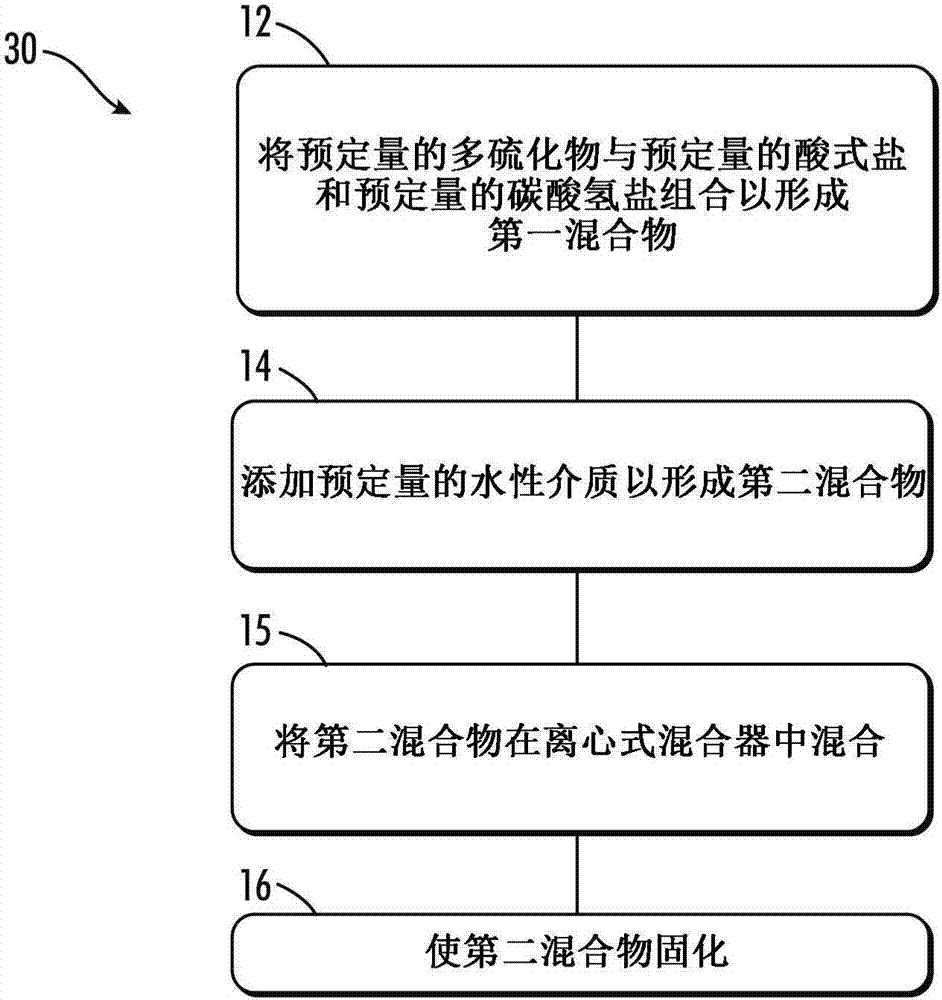

Method used

Image

Examples

Embodiment 1

[0059] A commercially available polysulfide composition, Pro-Seal 890F A-2 (PPG Aerospace), was removed from the refrigerator and thawed in a warm water bath for 10 minutes. The polysulfide ingredients were then dispensed in plastic cups, sodium bicarbonate and acid salt (sodium aluminum sulfate, Table 1) were weighed separately, and mixed with the polysulfide compound in a centrifugal mixer at a predetermined varying RPM. Time (ie, 15 seconds each at 800, 1400, 2000 and 2350 RPM). An aqueous medium comprising deionized water was added to the mixture, and the mixture was remixed in a centrifugal mixer at predetermined varying RPMs for predetermined times (ie, 15 seconds each at 800, 1400, 2000, and 2350 RPM). The sealant mixture was cured for 12 hours at atmospheric pressure in a mixing cup in a 120°F oven.

[0060] Once fully cured, density measurements of the supply polysulfide compound and cured mixture (present as foamed sealant material) were made by cutting slices and m...

Embodiment 2

[0064] A commercially available polysulfide composition, Pro-Seal 890F A-2 (PPG Aerospace), was removed from the refrigerator and thawed in a warm water bath for 10 minutes. The polysulfide ingredients were then dispensed in plastic cups, sodium bicarbonate and acid salt (monocalcium phosphate, Table 2) were weighed separately, and mixed with the polysulfide compound in a centrifugal mixer at predetermined varying RPM Predetermined times (ie, 15 seconds each at 800, 1400, 2000 and 2350 RPM). An aqueous medium comprising deionized water was added to the mixture, and the mixture was remixed in a centrifugal mixer at predetermined varying RPMs for predetermined times (ie, 15 seconds each at 800, 1400, 2000, and 2350 RPM). The sealant mixture was cured in a mixing cup in a 120°F oven for 12 hours.

[0065] Once fully cured, density measurements of the supply polysulfide compound and cured mixture (present as foamed sealant material) were made by cutting slices and measuring the v...

Embodiment 3

[0069] Commercially available polysulfide composition AC-770 (3M - Aerospace Sealants, Garden Grove, CA) was removed from the refrigerator and thawed in a warm water bath for 10 minutes. The polysulfide components were then dispensed in plastic cups, sodium bicarbonate and acid salt (sodium acid pyrophosphate, Table 3) were weighed separately, and mixed with polysulfide compound in a centrifugal mixer at a predetermined changing RPM Mix for a predetermined time (ie, 15 seconds each at 800, 1400, 2000 and 2350 RPM). An aqueous medium comprising deionized water was added to the mixture, and the mixture was remixed in a centrifugal mixer at predetermined varying RPMs for predetermined times (ie, 15 seconds each at 800, 1400, 2000, and 2350 RPM). The sealant mixture was cured in a mixing cup in a 120°F oven for 12 hours.

[0070] table 3

[0071]

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cross-linking density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com