Carbon-aluminum composite material heald frame

A technology of aluminum composite materials and heald frames, which is applied in healds, textiles, papermaking, textiles, etc., can solve the problems of increasing actual costs, complex structures, and high cost of magnesium alloy materials, and achieves easy production or manufacturing and low material costs , Improve the effect of vibration reduction and sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

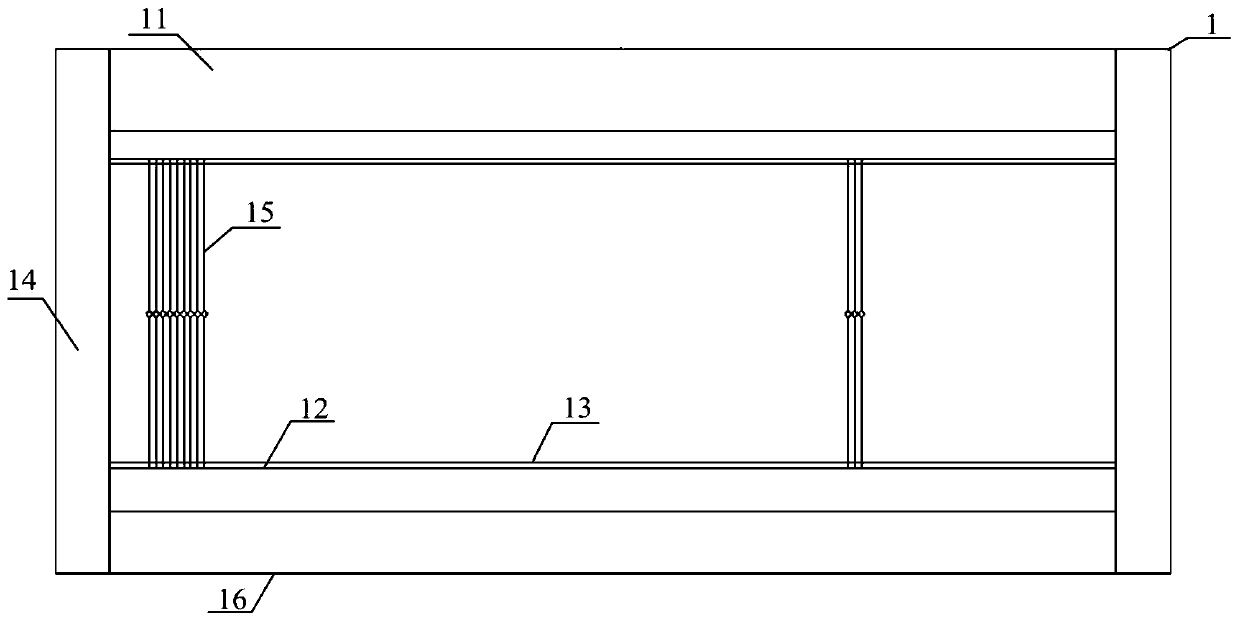

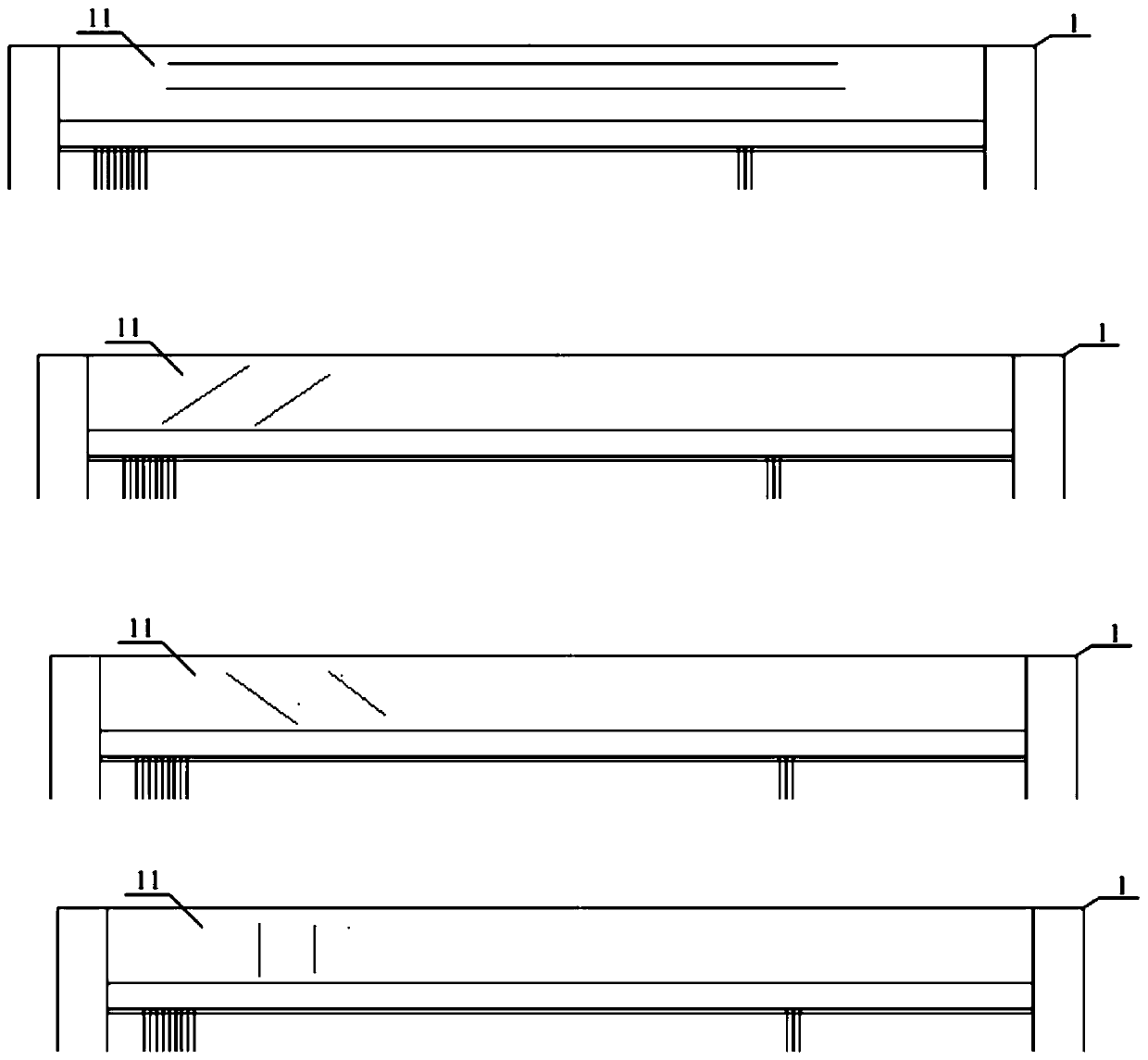

[0037] Embodiment 1, a kind of carbon-aluminum composite material heald frame, as Figure 1-3 As shown, a rectangular frame 1 consisting of healds 15 and two transverse elements 11 and two lateral supports 14 is included, and two installation rails 13 parallel to the transverse elements 11 are provided in the inner cavity of the rectangular frame 1 , A heald 15 is installed between the two installation rails 13, and the heald 15 is perpendicular to the installation rail 13. details as follows:

[0038] The two transverse elements 11 comprise an upper transverse element and a lower transverse element, and the two lateral supports 14 comprise a left lateral support and a right lateral support. The mutually facing surfaces of the two transverse elements 11 are called inner sides 12 , and the surfaces of the transverse elements 11 opposite the inner sides 12 are called outer sides 16 . The transverse element 11 is provided with mounting rails 13 on the inner side 12 , and a hedd...

Embodiment 2

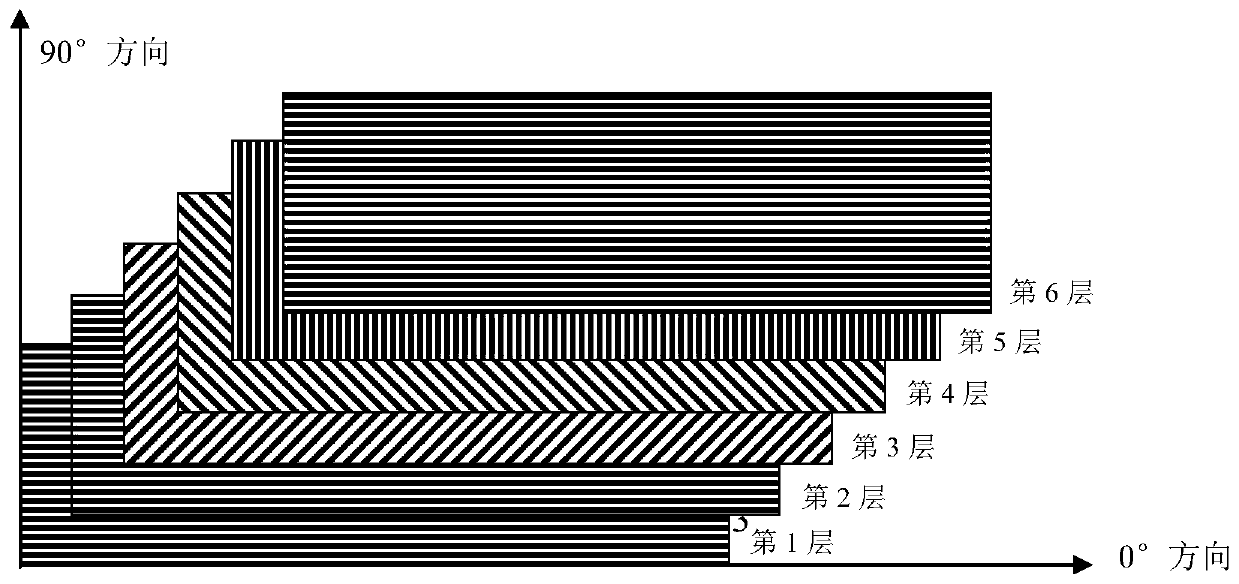

[0051] Embodiment 2, make the following changes to the reinforcement layer assembly 22 in Embodiment 1:

[0052] The reinforcement layer assembly 22 is composed of 8 layers of carbon fiber prepreg layers arranged on the outer surface of the transverse element 11 in sequence, the 8 layers of carbon fiber prepreg layers from inside to outside, the carbon fiber prepreg layer of each layer of carbon fiber prepreg layer The laying angles of the fiber directions of the impregnation relative to the installation rail 13 are 0° / 0° / 45° / -45° / 0° / 0° / 90° / 0° respectively.

[0053] The rest are equal to Example 1.

Embodiment 3

[0060] Embodiment 3, heald frame, change its transverse element 11, all the other are equal to embodiment 1, as Figure 4 shown.

[0061] The transverse element 11 includes a hollow profile 35, and at least one profile cavity is provided in the profile 35 (generally a profile cavity 1 31, a profile cavity 2 32 and a profile cavity 3 33 are provided, a total of three profile cavities), at least one A filling element 28 is arranged in the profile cavity, and a profile reinforcement layer 34 is provided on the outer surface of the profile 35; a concave heald frame support rail 36 used in conjunction with the installation track 13 is provided at one end of the profile 35, and a heald frame support rail 36 is provided with Groove 37, installation rail 13 is fixed on heald frame support rail 36 and has groove 37. The heald frame support rail 36 and the profile 35 are integrally formed.

[0062] The heald frame support rail 36 of the transverse element 11 in embodiment 3 is better ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com