Underground engineering waterproof structure and construction method thereof

A technology of underground engineering and waterproof structure, which is applied in the direction of infrastructure engineering, construction, protection devices, etc., can solve the factors that increase the instability of the enclosure structure of the foundation pit, the high cost of brick and tire membrane materials and labor costs, and affect the full sealing and waterproofing. Effectiveness and other issues, to achieve the effect of reducing material costs and labor costs, shortening waterproof construction period, and conducive to stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

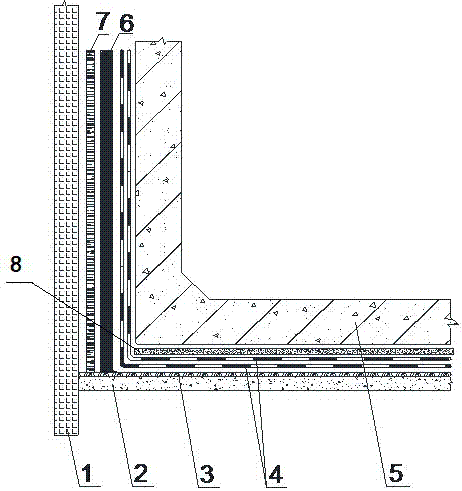

[0042] combine figure 1 As shown, a waterproof structure for underground engineering, an enclosure structure 1 is arranged on the side wall of the pre-excavated foundation pit, a concrete cushion 2 is arranged on the bottom surface of the foundation pit, and a connection formwork 6 is fixed on the inner side of the enclosure structure 1, and in the formwork 6 The waterproof membrane layer 4 is pasted on the side and the concrete pad 2 . Template 6 is a non-wall template.

[0043] In this embodiment, the enclosure structure 1 adopts the enclosure structure of steel sheet piles. In order to prevent the template 6 from being disturbed when the steel sheet pile enclosure structure is disassembled, an isolation layer 7 is also provided between the template 6 and the steel sheet pile enclosure structure. The isolation layer in this embodiment is made of foam board, and the foam board is first laid on the steel sheet The inner side of the pile enclosure structure, and then fix the ...

Embodiment 2

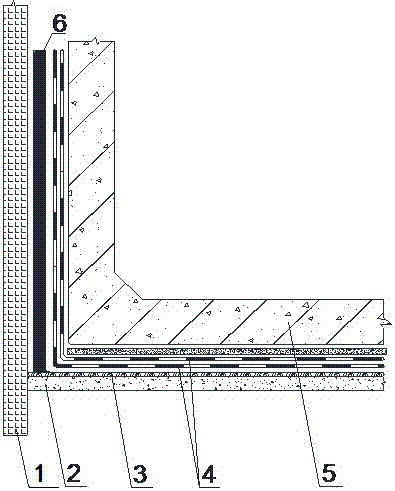

[0061] combine figure 2 As shown, a waterproof structure for underground engineering, an enclosure structure 1 is arranged on the side wall of the pre-excavated foundation pit, a concrete cushion 2 is arranged on the bottom surface of the foundation pit, a formwork 6 is fixedly connected to the inner side of the enclosure structure 1, and a formwork 6 is fixed on the inner surface of the formwork 6 The waterproof membrane layer 4 is pasted on the inner side and the concrete pad 2 . Template 6 is a non-wall template.

[0062] In this embodiment, the enclosure structure 1 adopts a concrete enclosure structure, and the concrete enclosure structure is more specifically an underground diaphragm wall, and it can also be drilled piles, excavated piles, concrete sheet piles, and SMW methods. One or both of the piles. The formwork 6 adopts a plastic formwork, and the inner surface of the formwork 6 is a flat surface, which can fit well with the waterproof membrane layer 4. The plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com