Dam body and reverse building method seamless waterproof construction technology thereof

A jointless, dam body technology, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve the problems of dam body waterproof function failure, dam body function and dam body structure safety impact, shortened dam body structure life cycle and other problems , to shorten the waterproof construction period, solve the problem of sealing water leakage, and achieve the effect of fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment:

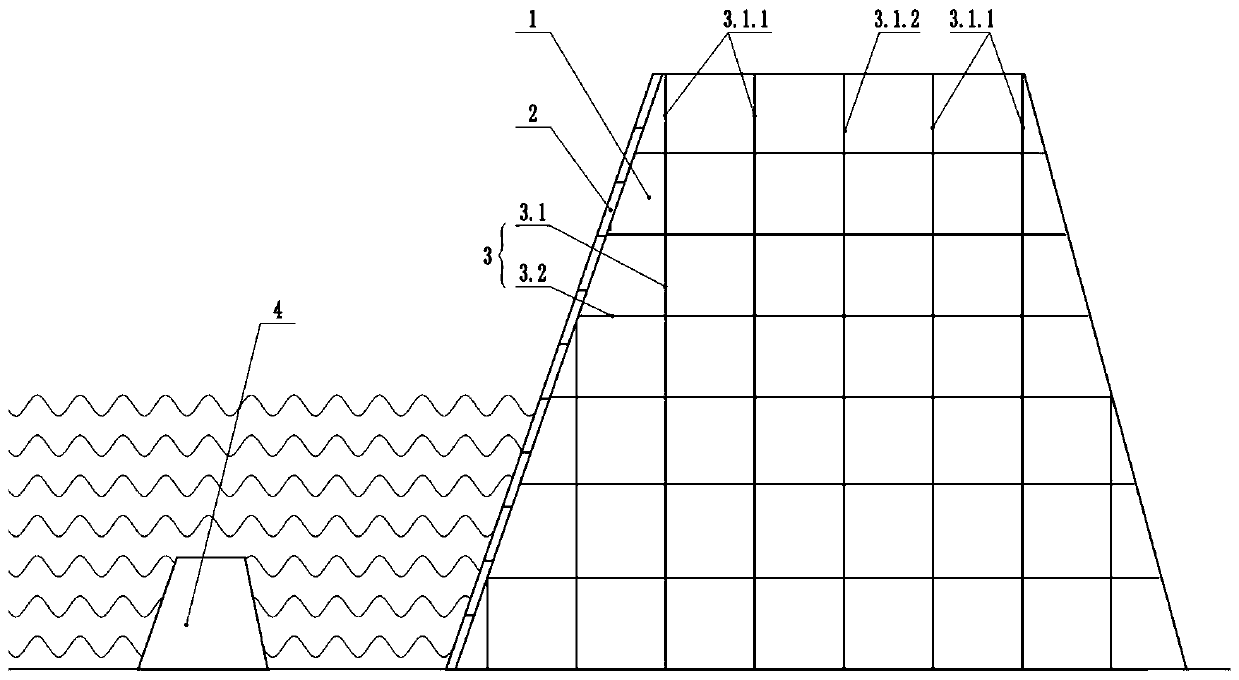

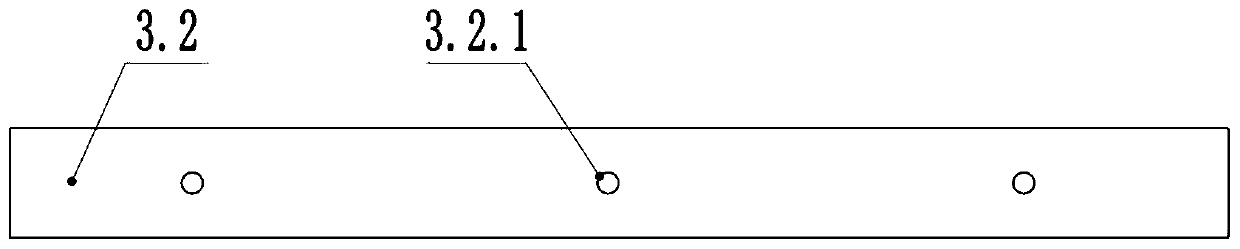

[0029] A dam body, the facing surface of the dam body 1 is laid with a composite concrete waterproof board 2, and the composite concrete waterproof board 2 is provided with inorganic composite ribs 3 to form a separate waterproof protection layer of the dam body, so as to solve the cracks on the foundation surface of the concrete structure of the dam body The problem is that the interior of the dam body 1 and the pile foundation of the foundation of the dam body 1 are provided with inorganic composite reinforcements 3 .

[0030] Further, the inorganic composite bars 3 are hollow tubular basalt fiber composite bars. Compared with high-tech fibers such as carbon fiber, aramid fiber, and ultra-high molecular weight polyethylene fiber (UHMWPE), basalt fiber not only has the characteristics of high strength and high modulus, but also has good high temperature resistance, oxidation resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com