Inner mold for filling mine

A mine filling and internal mold technology, which is applied to fillings, mining equipment, safety devices, etc., can solve problems such as low compressive strength, damage to groundwater, and high water content of mixture slurry, so as to improve the strength of the filling layer and reduce the Filling cost and effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

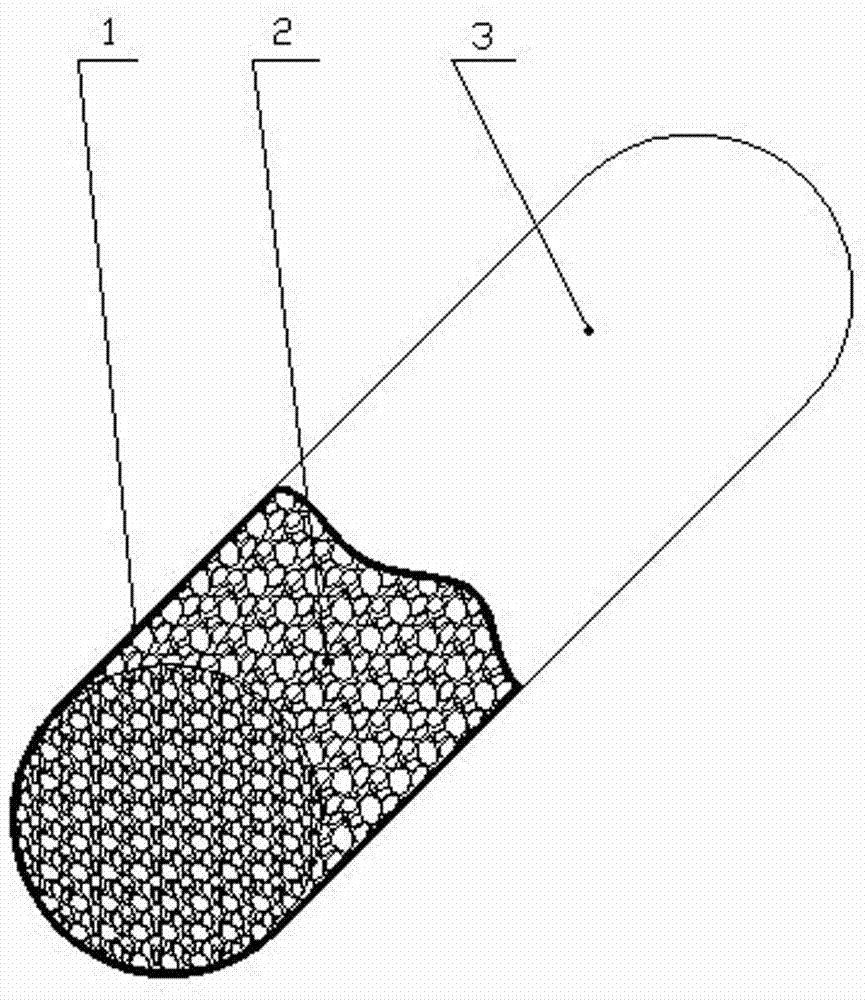

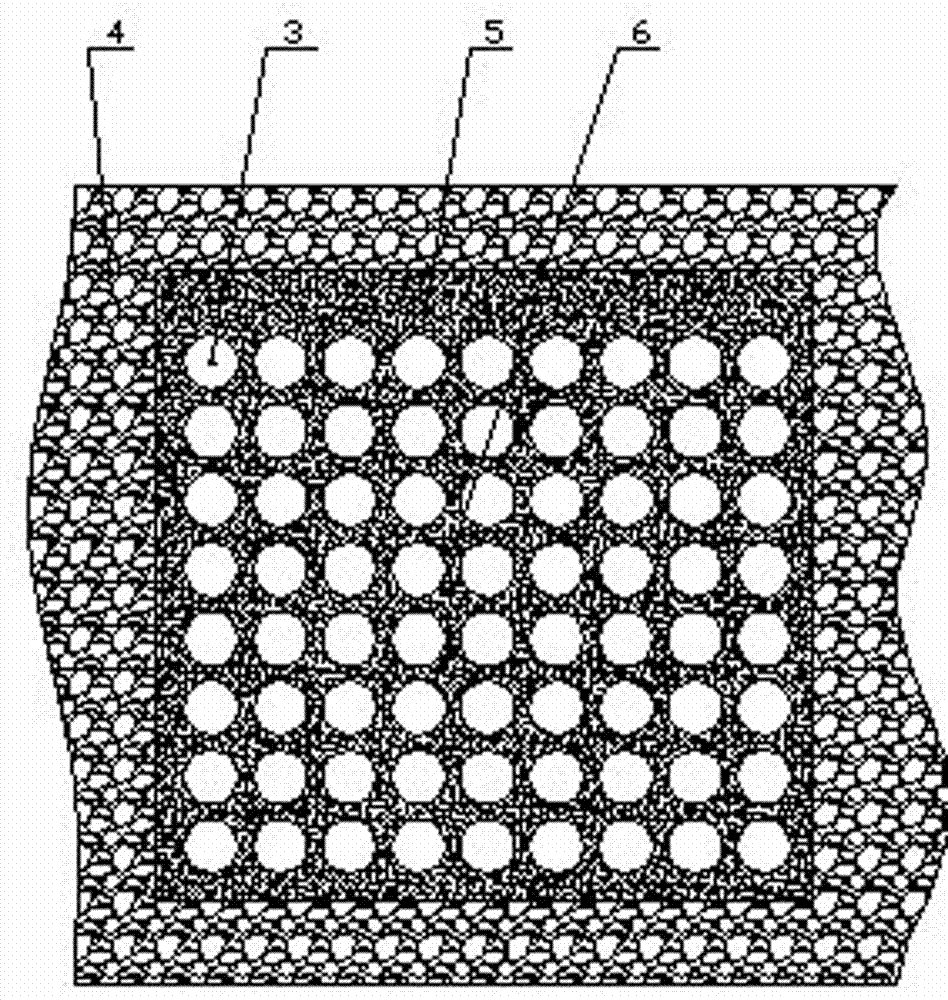

[0028] Embodiment 1, the inner mold 3 of the present invention includes an inner core 2 and an outer cladding layer 1, and the inner core 2 is formed by pressing or extruding solid waste materials and then wrapping the outer cladding layer 1 to form an inner mold 3. The inner mold 3 is filled in the concrete 5 to form an inner mold 6 for mine filling to fill the mine. By arranging the internal molds in a regular or irregular shape and fixing them in the goaf, a solid honeycomb structure is formed after pouring concrete to achieve the effect of mine filling, which can greatly improve the filling efficiency, reduce the filling cost and improve the strength of the filling layer. The honeycomb structure also has the effect of earthquake resistance and disaster reduction. The inner core is made of urban waste, which can effectively solve the problem of harmless disposal of urban waste, and is of great significance to the protection of the geological environment of mining areas and t...

Embodiment 2

[0029] Example 2, the inner mold 3 includes an inner core 2 and an outer cladding layer 1, and the inner core 2 is pressed or extruded from solid waste materials and pushed into the outer cladding layer 1 to form the inner mold 3. The mold 3 is filled in the concrete 5 to form the inner mold 6 for filling the mine to fill the mine. The outer cladding layer 1 is flexible or rigid cylindrical. refer to Figures 1 to 9 , all the other are with embodiment 1.

Embodiment 3

[0030] Embodiment 3, the outer cladding layer 1 is made of metal or non-metal, organic or inorganic or their mixture or modified material. refer to Figures 1 to 9 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com