Device for preparing micron-order and/or millimeter-order coated powder by intermittent electrodeposition and processing method thereof

A treatment method and coating technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve problems such as unsatisfactory coating uniformity and coating defects, and achieve the effects of uniform replenishment, uniform thickness controllable, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

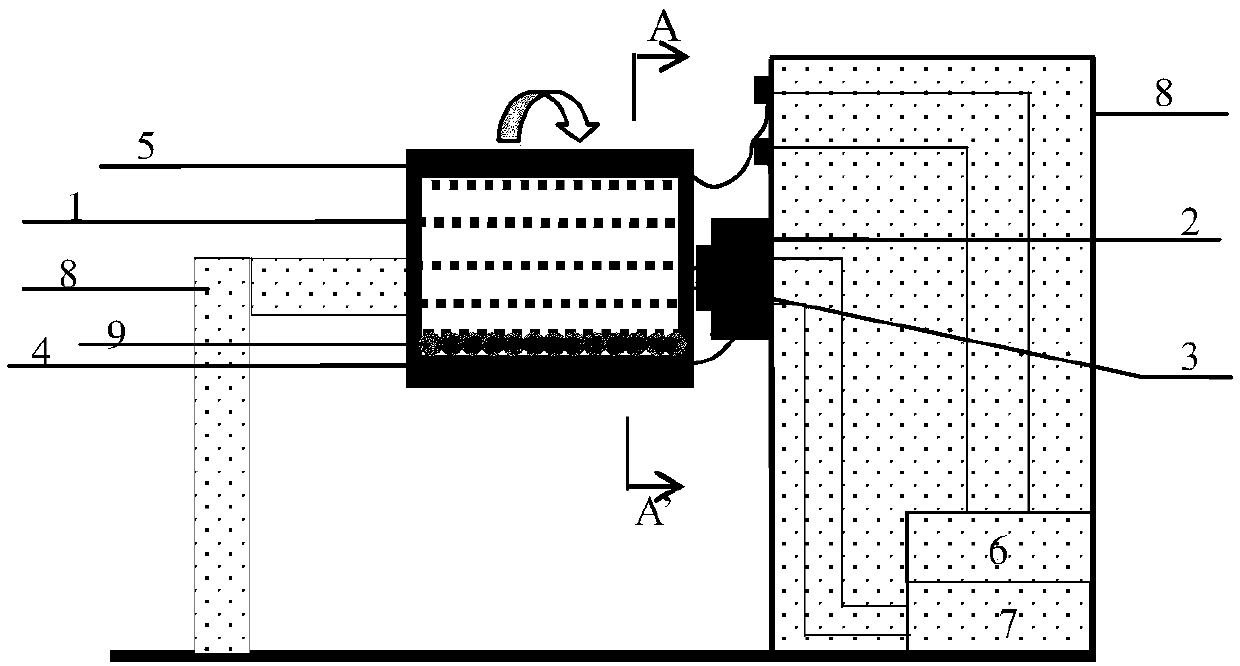

[0068] This embodiment provides a device for preparing coated powder by intermittent electrodeposition, such as figure 1 with figure 2 As shown, the device includes an electroplating tank 1, a power assembly, a cathode plate 4, an anode plate 5, a power supply 6, a power control device 7 and a support 8;

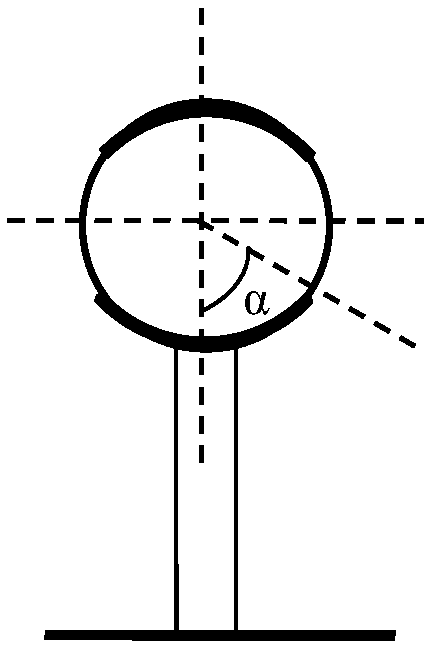

[0069] Wherein, a power assembly is arranged on one side of the electroplating tank 1, the cathode plate 4 is laid on the bottom of the electroplating tank 1, the anode plate 5 is arranged on the top of the electroplating tank 1 and is parallel to the cathode plate 4, and the power supply 6 is connected to the cathode plate 4 and the cathode plate 4 through wires. The anode plate 5 is connected; the power assembly includes a motor 2 and a motor transmission shaft 3, and the motor 2 is connected to one side of the electroplating tank 1 through the motor transmission shaft 3, and is sealed; the power assembly drives the electroplating tank 1 to rotate around the central axis ...

Embodiment 2

[0072] This embodiment provides a device for preparing coated powder by intermittent electrodeposition. The structure of the device is the same as that of Embodiment 1, the only difference is that the electroplating tank 1 is a closed cylinder; the cathode plate 4 The length is less than the length of the electroplating tank 1, the cathode plate 4 is a two-dimensional rectangle, the material of the cathode plate 4 is stainless steel, and the material of the anode plate is Sn-Ag alloy.

Embodiment 3

[0074] This embodiment provides a device for preparing coated powder by intermittent electrodeposition. The structure of the device is the same as that of Embodiment 1, the only difference being that the material of the cathode plate 4 is copper, and the material of the anode plate is Fe- Ni alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com