Preparation method of submicron SiO2/polyethylene glycol modified foam polyurethane composite material

A polyethylene glycol modified and foamed polyurethane technology, applied in the field of polymer composite materials, can solve problems such as limited application temperature range, and achieve excellent impact resistance and protection performance, good physical and chemical stability, and uniform foam pores. delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

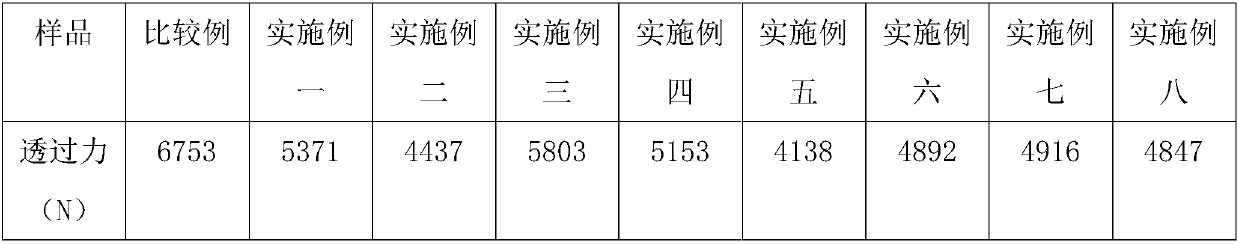

Examples

Embodiment 1

[0024] A preparation method of submicron SiO2 / polyethylene glycol modified foamed polyurethane composite material is carried out in sequence according to the following steps:

[0025] Step 1: Use polyethylene glycol 200 and silica with a particle size of 100nm to mix uniformly, and then add hydroxy-terminated silicone oil with a degree of polymerization of 80 to make STF base material. The polyethylene glycol 200: silica mass ratio is 60: 40. The mass ratio of hydroxyl-terminated silicone oil: polyethylene glycol / silica mixture is 1:99.

[0026] Step 2: Mix the STF base material and the foamed polyurethane A material to obtain a foam preparation. The mass ratio of the STF base material to the foamed polyurethane A component is 0.5:99.5.

[0027] Step 3: Mix and foam the foam preparation obtained in Step 2 with the foamed polyurethane B material (the mixing ratio is fixed at 100:55) to prepare a 1 cm thick foamed board to obtain submicron SiO2 / polyethylene glycol modified Polyurethan...

Embodiment 2

[0029] A preparation method of submicron SiO2 / polyethylene glycol modified foamed polyurethane composite material is carried out in sequence according to the following steps:

[0030] Step 1: Use polyethylene glycol 200 and 950nm silica to mix uniformly, and then add hydroxy-terminated silicone oil with a degree of polymerization of 1000 to make STF base material. The weight ratio of polyethylene glycol 200: silica is 55:45, the mass ratio of hydroxyl-terminated silicone oil:polyethylene glycol / silicon dioxide mixture is 30:70.

[0031] Step 2: Mix the STF base material and the foamed polyurethane A material to obtain a foam preparation. The mass ratio of the STF base material to the foamed polyurethane A component is 18:82.

[0032] Step 3: Mix and foam the foam preparation obtained in Step 2 with the foamed polyurethane B material to prepare a 1 cm thick foamed board to obtain a submicron SiO2 / polyethylene glycol modified foamed polyurethane composite material.

Embodiment 3

[0034] A preparation method of submicron SiO2 / polyethylene glycol modified foamed polyurethane composite material is carried out in sequence according to the following steps:

[0035] Step 1: Use polyethylene glycol 400 and silica with a particle size of 100nm to mix uniformly, and then add hydroxy-terminated silicone oil with a degree of polymerization of 80 to make STF base material. The weight ratio of polyethylene glycol 400: silica is 60: 40. The mass ratio of hydroxyl-terminated silicone oil: polyethylene glycol / silica mixture is 1:99.

[0036] Step 2: Mix the STF base material and the foamed polyurethane A material to obtain a foam preparation, and the mass ratio of the STF base material to the foamed polyurethane A component is 0.5:99.5.

[0037] Step 3: Mix and foam the foam preparation obtained in Step 2 with the foamed polyurethane B material to prepare a 1 cm thick foamed board to obtain a submicron SiO2 / polyethylene glycol modified foamed polyurethane composite material....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com