Quickly mounted pipeline structure

A pipeline and quick installation technology, applied in the direction of pipeline supports, pipes, branch pipelines, etc., can solve the problem of inconvenient operation of pipeline maintenance, cleaning, and checking the wear degree of the inner pipe, clogging of the fine chip pipeline system, and easy breakage of the raw material belt. and other problems to achieve the effect of good inner wall finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

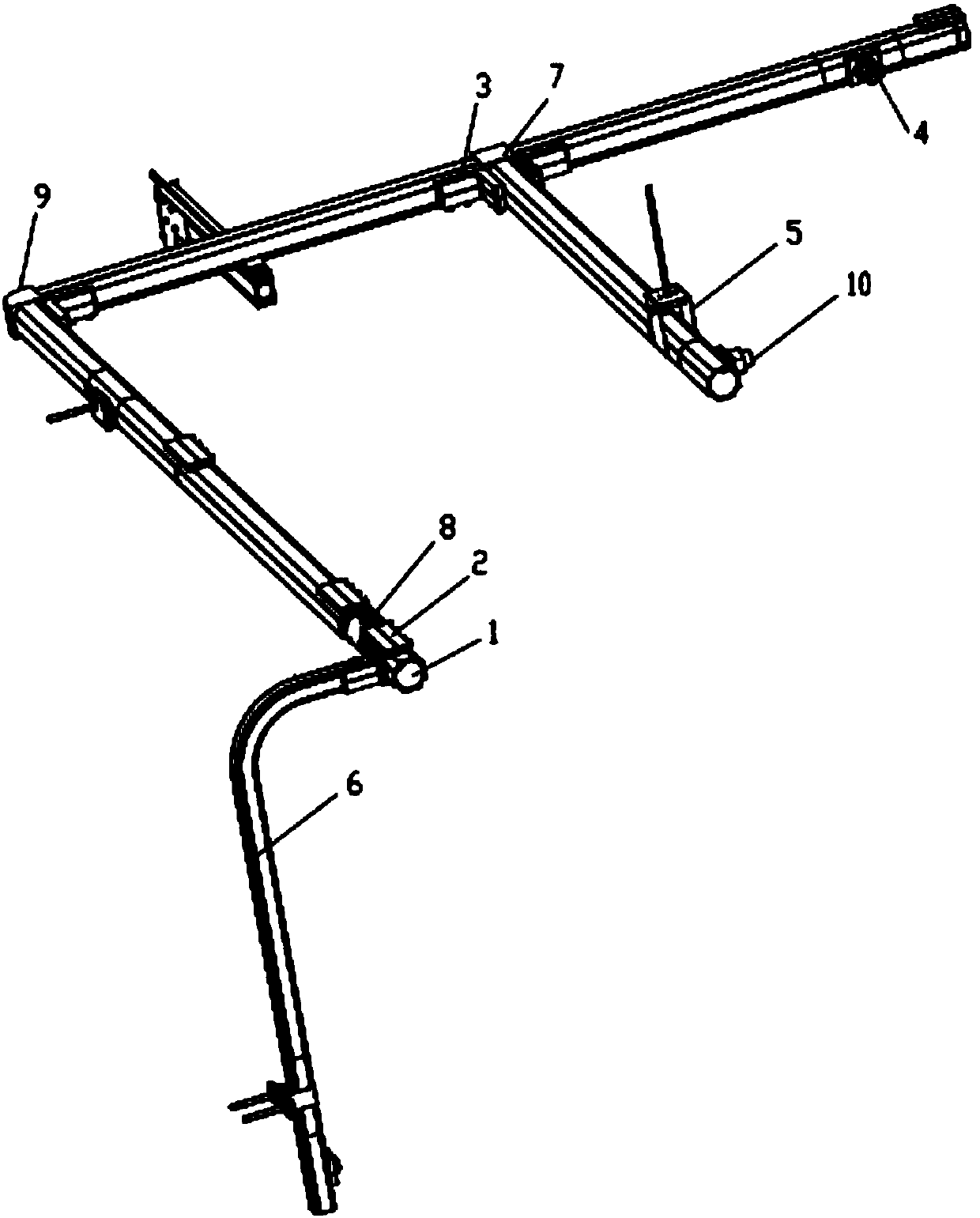

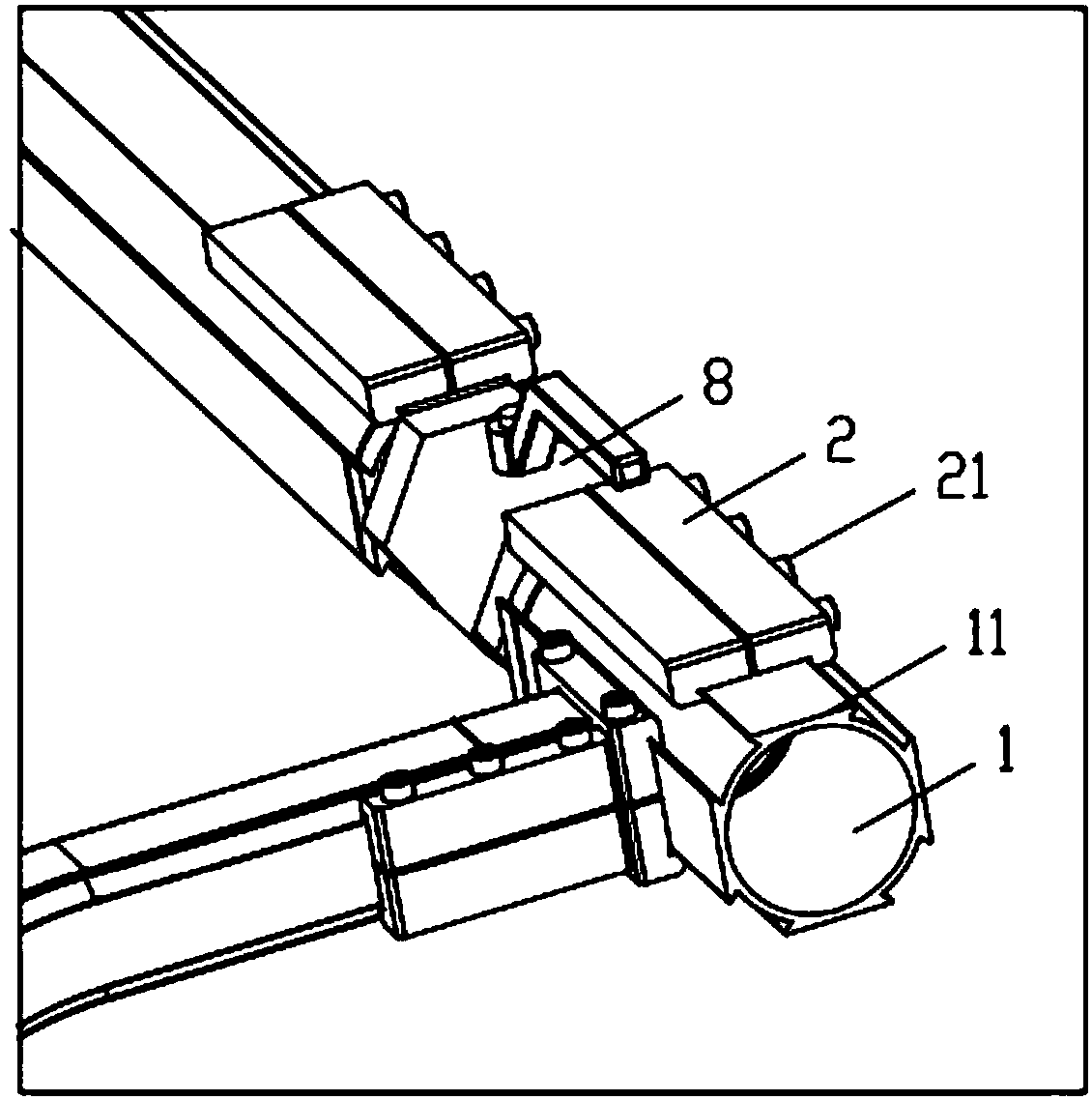

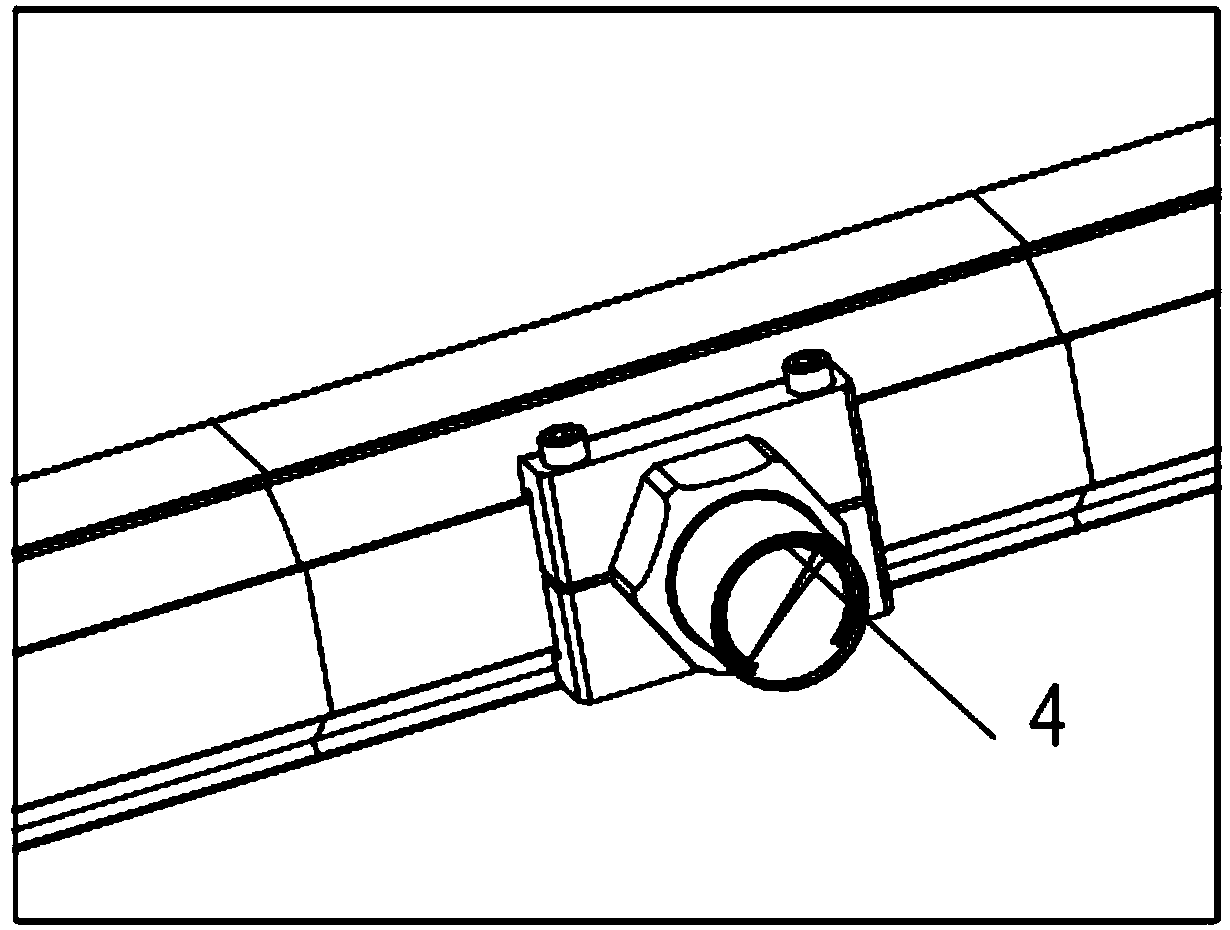

[0029] Such as Figure 1-13 As shown, a fast-installed pipeline structure includes a pipe body 1 and pipe fittings. The outer wall of the pipe body 1 is provided with a number of parallel longitudinal installation grooves 11, which run through the entire outer wall of the pipe body 1. Due to the groove structure, the cross section of the pipe body 1 The outer shape of the outer ring is similar to that of a petal, and the inner ring is still circular. The pipe fittings include a clamping spacer and a connecting sealing pipe. The clamping spacer is installed on the outside of the pipe body 1. When the pipe body and the pipe body are butted, the connecting sealing pipe is installed in the pipe body 1, bridges the two pipe bodies, and communicates with the pipe body. Seal the connection gap between the pipe bodies, and the clamping spacer is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com