Immersed type graphite heat exchanger

A graphite heat exchanger, immersion technology, applied in the direction of heat exchanger shell, graphene, heat exchange equipment, etc., can solve the problems of affecting heat transfer efficiency and corrosion resistance, affecting heating efficiency, poor structural strength, etc. The effect of saving structural materials, good structural uniformity and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

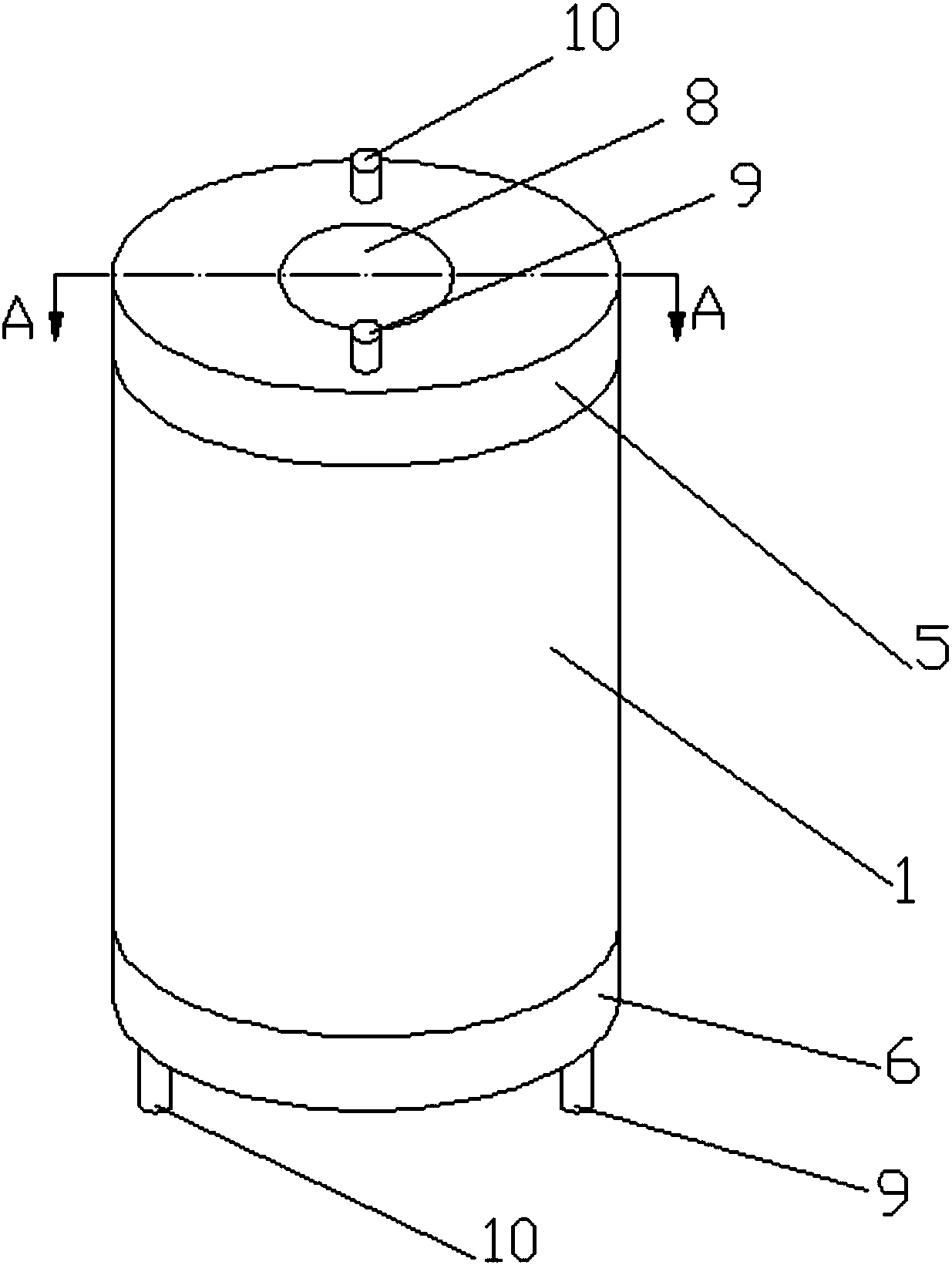

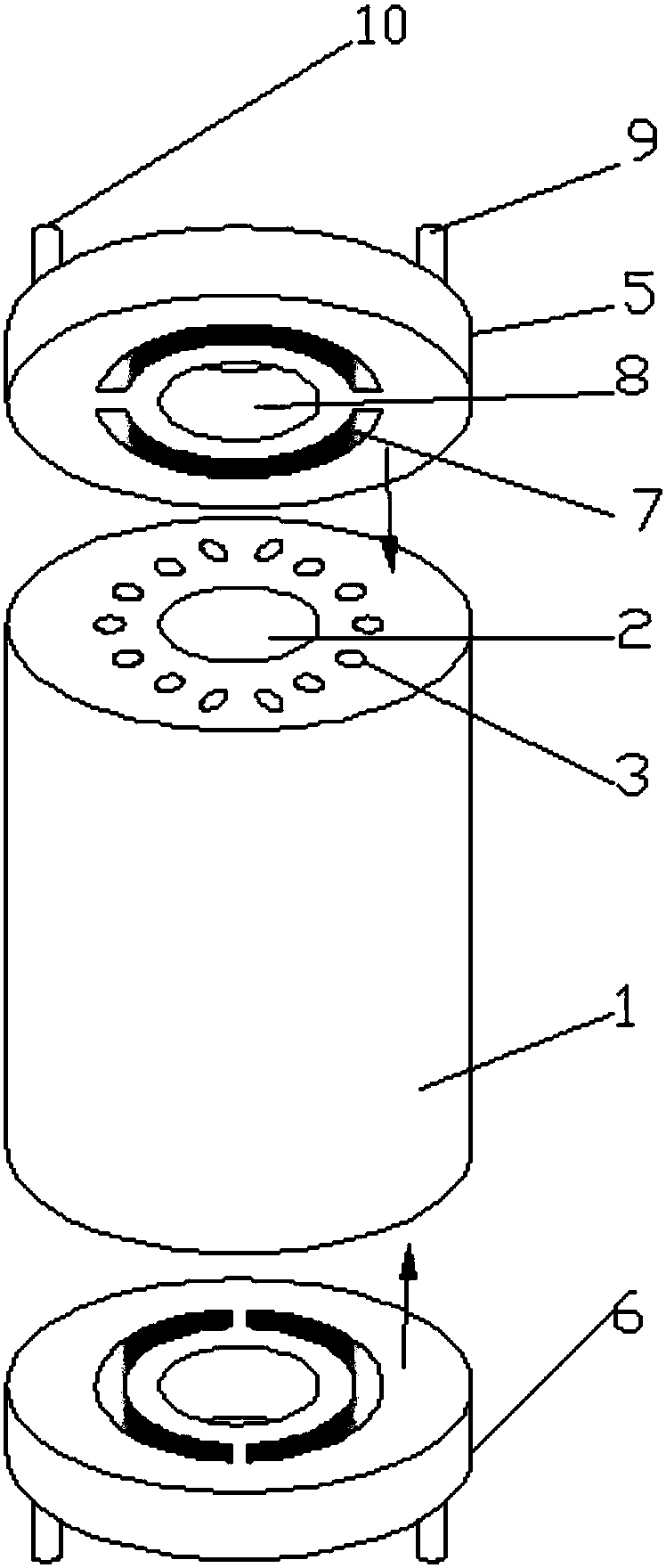

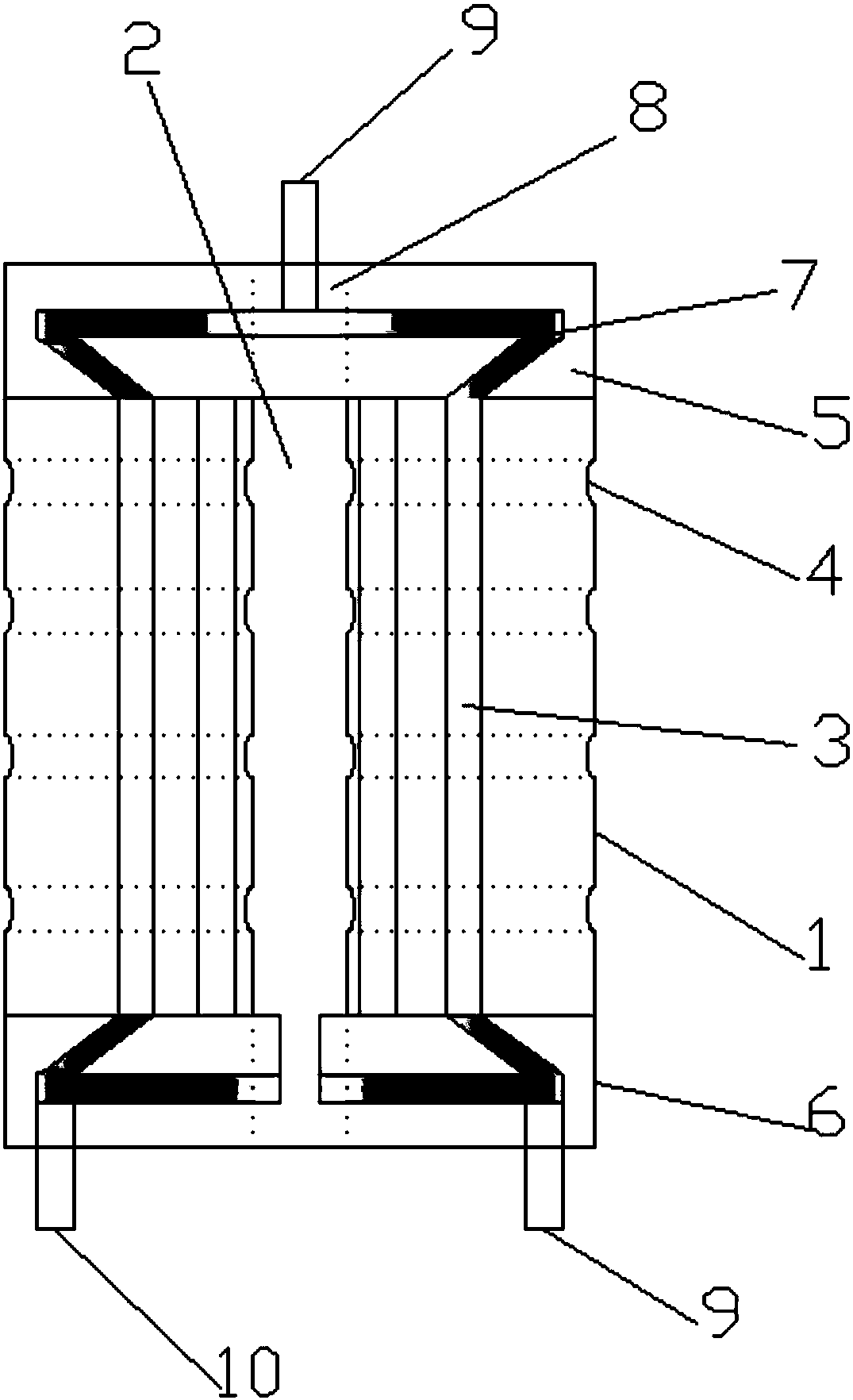

[0031] refer to Figure 1-4 , an immersed graphite heat exchanger, comprising a hollow graphite column 1, the hollow graphite column 1 is cylindrical, the center of the hollow graphite column 1 is a first circular through hole 2, the hollow graphite column 1 The end face is provided with annularly distributed longitudinal heating holes 3, the longitudinal heating holes 3 are parallel to the first circular through hole 2 and run through the two end faces of the hollow graphite column 1, the inner wall of the hollow graphite column 1 is provided with transverse The feed holes 4, the transverse feed holes 4 penetrate to the outer wall of the hollow graphite column 1, the transverse feed holes 4 located on the same surface are distributed in a divergent ring, and the transverse feed holes 4 and the longitudinal heating holes 3 They are not connected to each other, and the transverse feeding holes 4 are divided into multiple layers and distributed equidistantly along the column wal...

Embodiment 2

[0045] refer to Figure 1-4, an immersed graphite heat exchanger, comprising a hollow graphite column 1, the hollow graphite column 1 is cylindrical, the center of the hollow graphite column 1 is a first circular through hole 2, the hollow graphite column 1 The end face is provided with annularly distributed longitudinal heating holes 3, the longitudinal heating holes 3 are parallel to the first circular through hole 2 and run through the two end faces of the hollow graphite column 1, the inner wall of the hollow graphite column 1 is provided with transverse The feed holes 4, the transverse feed holes 4 penetrate to the outer wall of the hollow graphite column 1, the transverse feed holes 4 located on the same surface are distributed in a divergent ring, and the transverse feed holes 4 and the longitudinal heating holes 3 They are not connected to each other, and the transverse feeding holes 4 are divided into multiple layers and distributed equidistantly along the column wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com