On-line monitoring device for oil pollution of hydraulic system and monitoring method

A technology for hydraulic system and oil pollution, which is applied in the field of online monitoring of oil pollution of hydraulic system, can solve the problems of low accuracy, large variation range, complicated equipment, etc., achieve stable working state, shorten the life of equipment, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

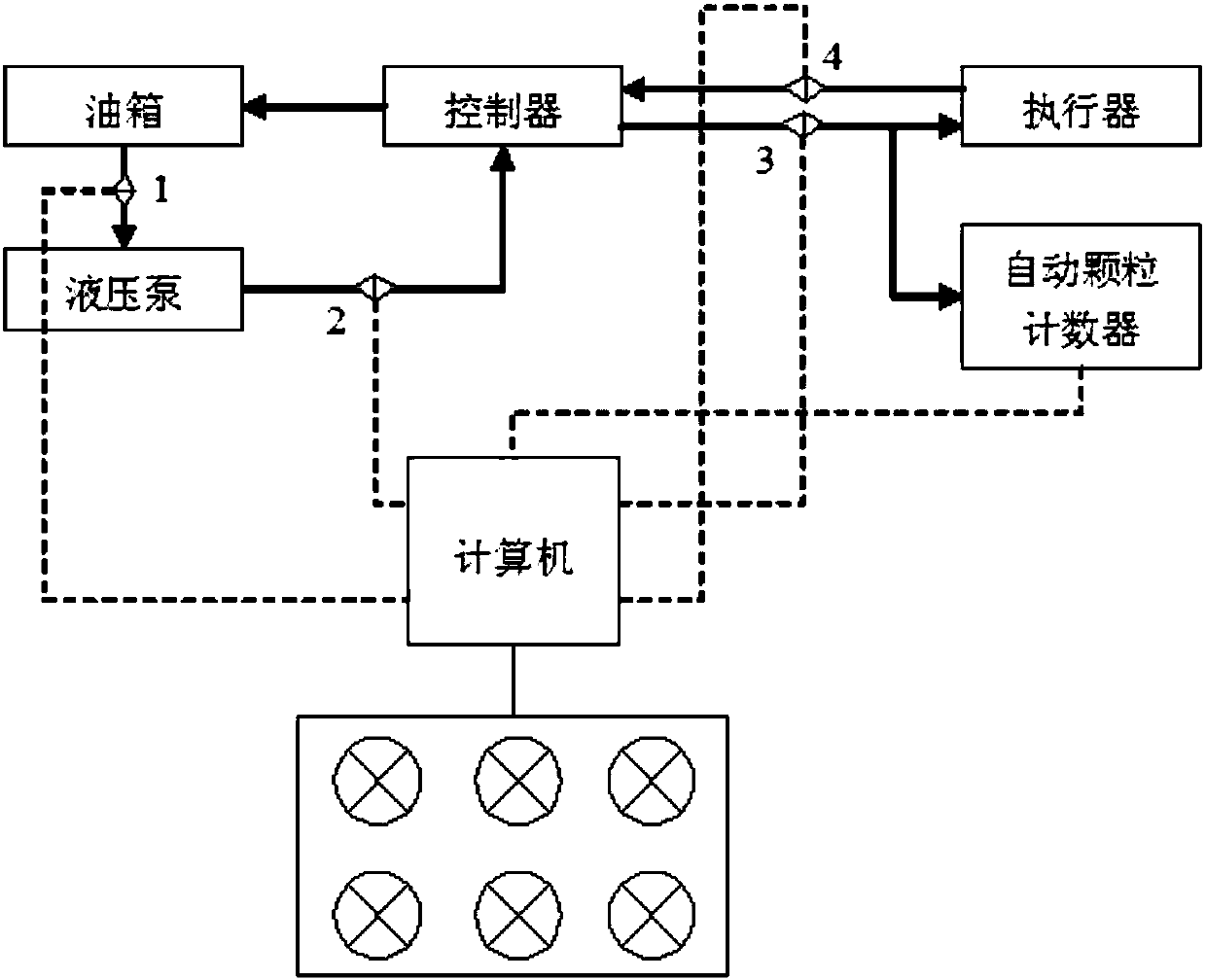

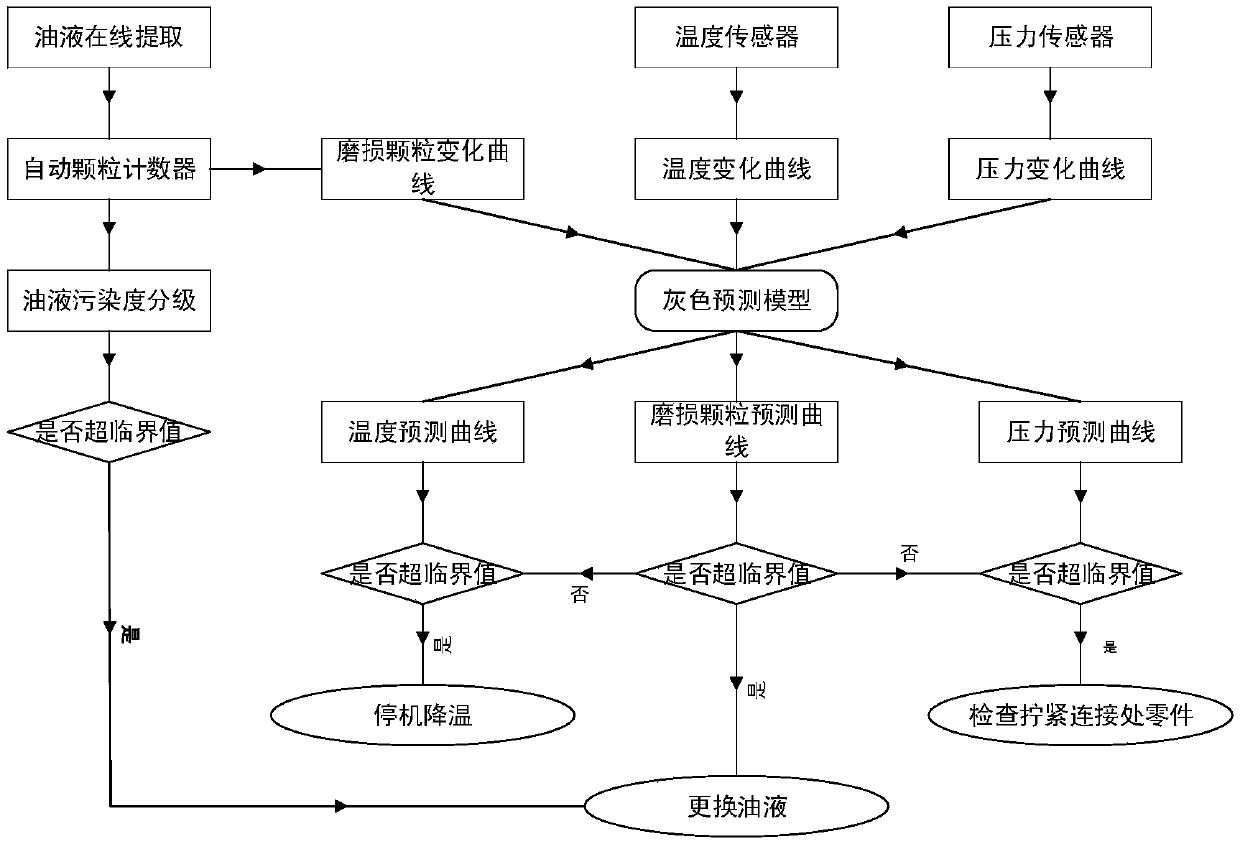

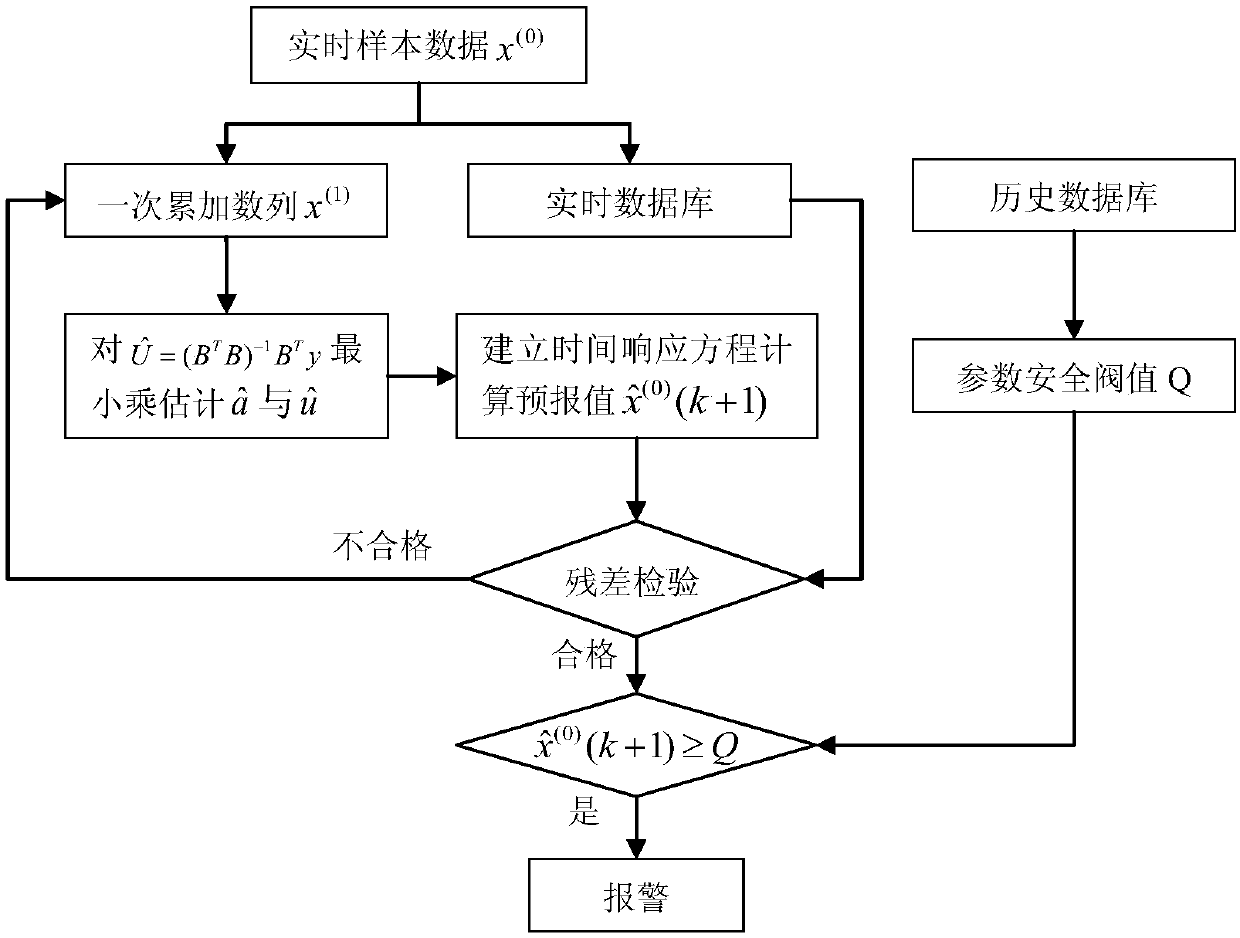

[0036] When the hydraulic system works normally, the system parameters are all working near the design and set values. If these parameters deviate from the predetermined values during work, the system will fail or may fail. For example, the working temperature of a reasonably designed hydraulic system changes. The range is limited, and the abnormal rise of system temperature often means that there is a fault in the system, and the system pressure comprehensively reflects the working status of the system and its components. According to the characteristics of the hydraulic system and the parameters to be measured, a new online monitoring method and device for oil pollution in the hydraulic system are designed. For the pressure and temperature of the main working parameters, it is only necessary to set sensor measuring points at the inlet and outlet of the pump (1, 2) and the inlet and outlet of the actuator (3, 4), and measure the pressure and temperature of four points 1, 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com