Optical module, SFP+ module with TO-CAN packaging and SFP+ module with COB packaging

A technology of optical components and optical paths, applied in the coupling of optical waveguides, etc., can solve the problems of large phase difference of optical components, narrow transition band, and difficult film system design, so as to meet structural requirements, improve coupling efficiency, and miniaturize the size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

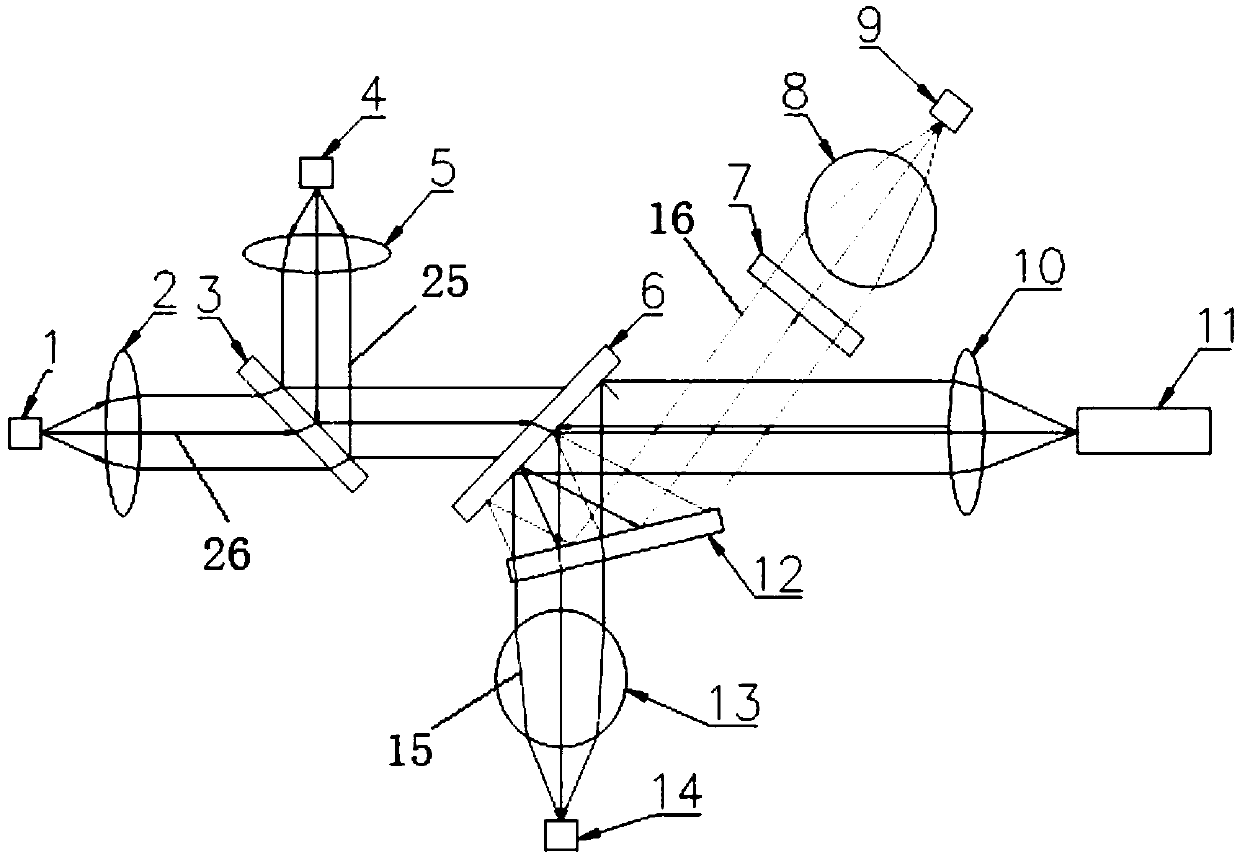

[0029] As an optimization scheme of the embodiment of the present invention, please refer to figure 1 , the angle α between the second filter 12 and the collimated outgoing light from the optical port 11 , 0figure 1 Among them, the angle between the second filter 12 and the horizontal line (that is, the outgoing light of the optical port end 11) is α, and when it is greater than 15°, the second filter 12 cannot completely combine the first uplink light 15 and the second Uplink light 16 splits away. Preferably, the best effect can be achieved when 13° is selected.

[0030] To further optimize the above scheme, please refer to figure 1 , the optical path between the second receiving end 9 and the second filter 12 is provided with a third filter 7, the second uplink light 16 passes through the third filter 7 and enters the second receiving end 9, the third filter 7 and The angle γ=90°+4α between the outgoing lights of the optical ports 11 . The angle between the third filter 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com