Method for nano-scale periodic poling of lithium niobate film

A technology of periodic polarization and lithium niobate, which is applied in nonlinear optics, pattern surface photolithography, optics, etc., can solve the problem that the polarization period cannot reach the nanometer level, and achieve simple and effective yield and preparation The effect of a simple, simplified polarization setup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

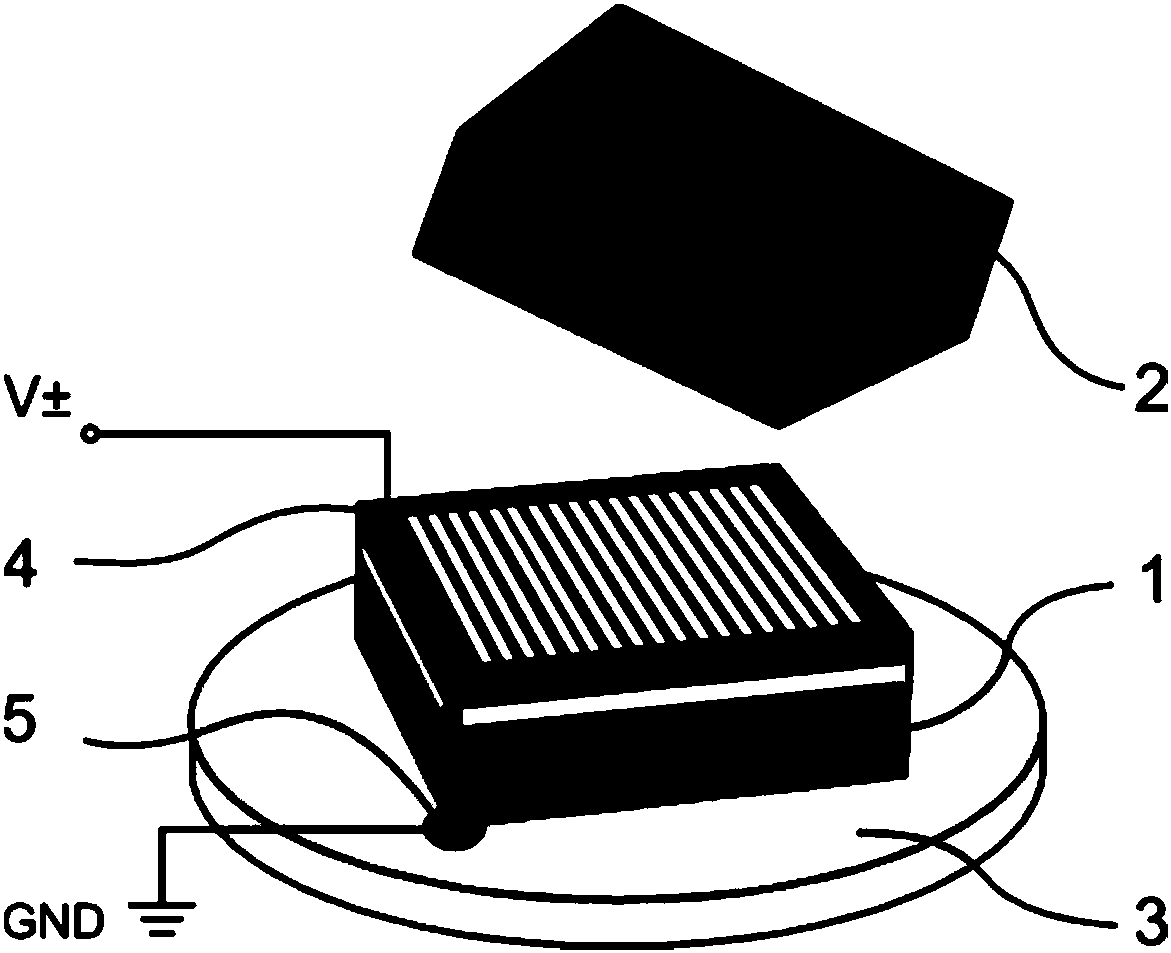

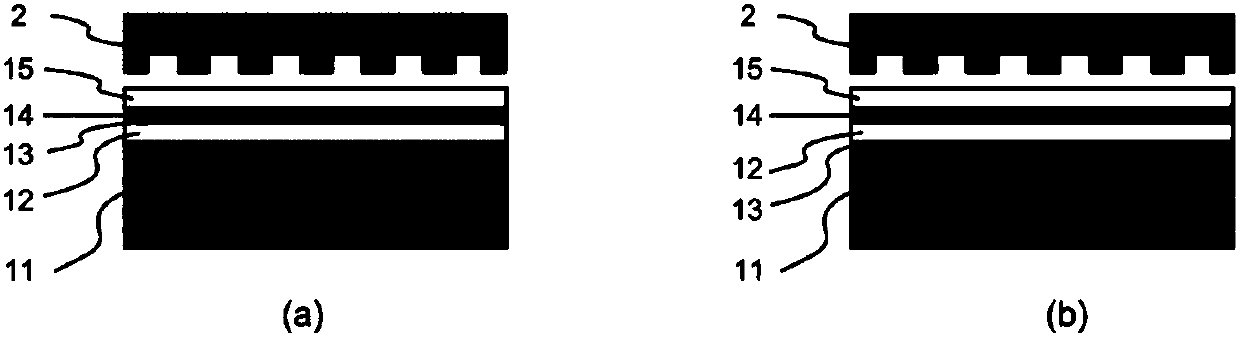

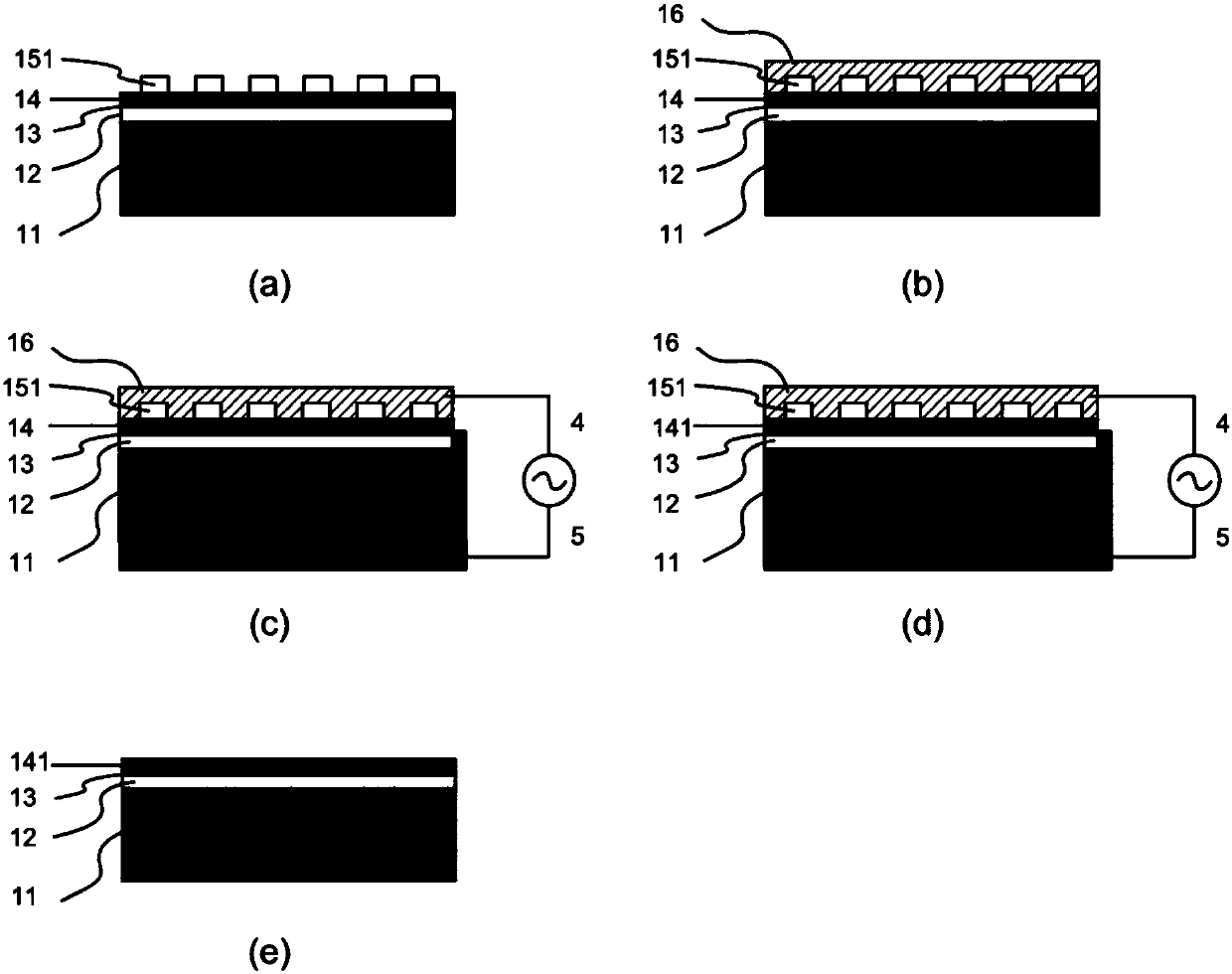

[0021] In this embodiment, two kinds of lithium niobate single crystal thin film samples with different structures are adopted, specifically as figure 2 As shown in a, it is a lithium niobate substrate 11, a silicon dioxide layer 12, a conductive electrode 13, a lithium niobate single crystal thin film layer 14, and an adhesive layer 15; and figure 2 As shown in b, it is a lithium niobate substrate 11, a conductive electrode 13, a silicon dioxide layer 12, a lithium niobate single crystal thin film layer 14, and a glue layer 15. The two lithium niobate thin film structures adopted are basically the same. Except for the slight difference in the value of the applied polarization voltage during the implementation of the electric polarization, other steps and methods are the same.

[0022] The lithium niobate single crystal thin film is Z-cut and has a thickness of 300-700nm.

[0023] This embodiment includes the following steps:

[0024] Such as figure 2 As shown, first, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com