Quick dismounting type hub motor

A wheel hub motor and quick-release technology, which is applied in the field of electric vehicles, can solve problems such as unfavorable cable fixing, heavy weight of a single unit, unfavorable folding/disassembly of the whole vehicle, etc., and achieve a simple and practical appearance, reduce the weight of a single unit, The effect of easy detachment and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

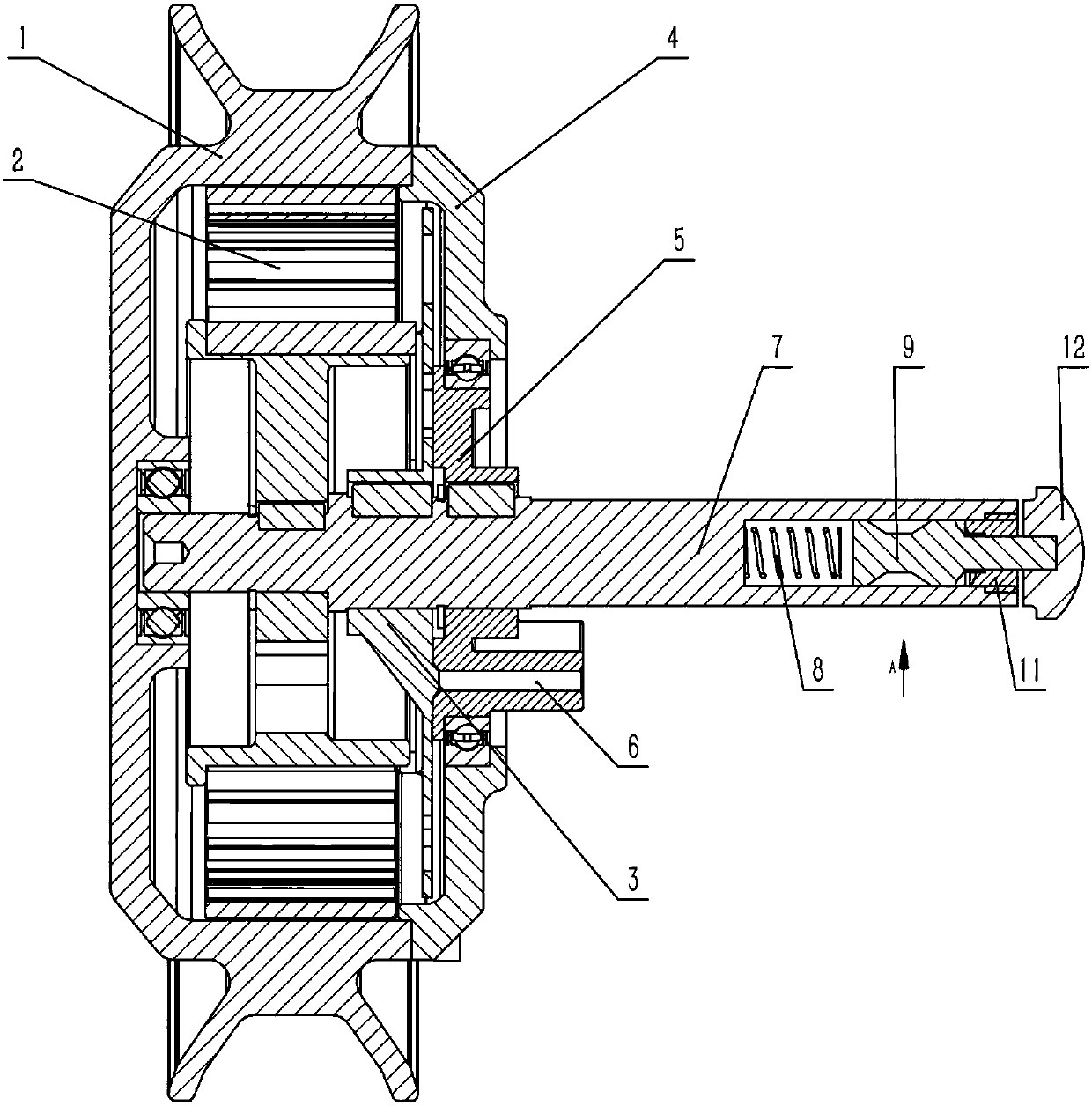

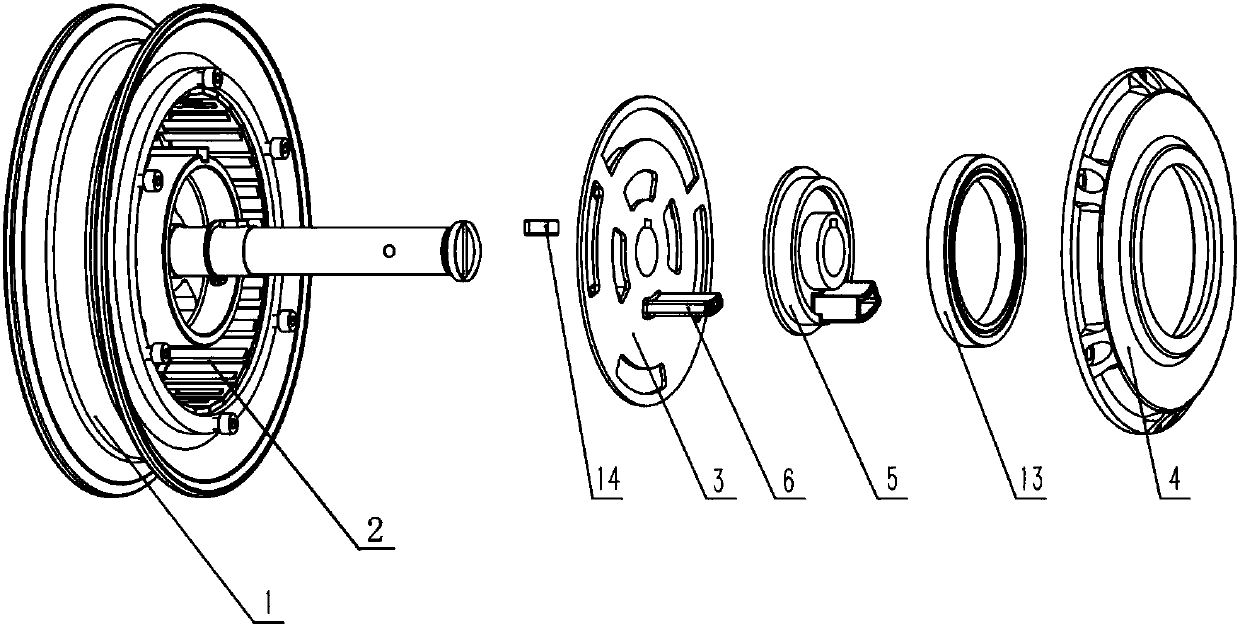

[0027] A quick-detachable in-wheel motor includes a motor hub 1, a motor shaft 7, a stator group 2, a terminal fixing frame 3, a terminal socket 6, a transition cover 5, an end cover 4, a push rod 9 and a quick-release knob 12.

[0028] The motor hub 1 is used as a motor casing with an opening on one side.

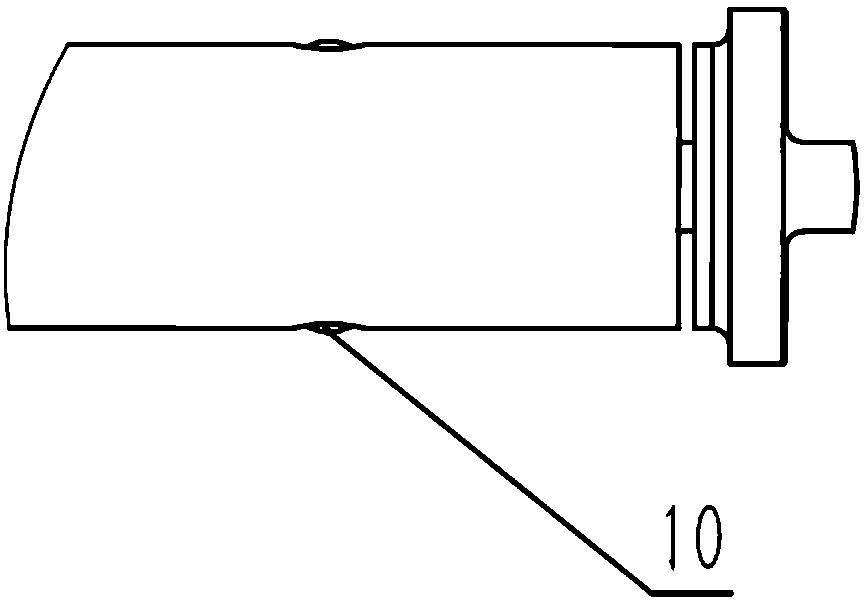

[0029] The driving section of the motor shaft 7 passes through the opening of the motor hub 1 and is rotatably fixed at the center of the inner wall of the motor hub 1 through the first bearing member.

[0030] The stator assembly 2 is fixed on the driving section of the motor shaft 7 and located inside the motor hub 1 .

[0031] The terminal fixing frame 3 is radially fixed on the driving section of the motor shaft 7 through a flat key, and is close to the outside of the stator group 2 . The terminal socket 6 is arranged on the outer surface of the terminal fixing frame 3 for connecting the stator coil and the external circuit.

[0032] The terminal socket (plug) is mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com