Cleaning method for the cleaning box and the inner wall of the cleaning box

A technology for cleaning boxes and cleaning liquids, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problems of low cleaning efficiency of the inner wall of the cleaning box, and improve self-cleaning efficiency and manufacturing efficiency. , the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

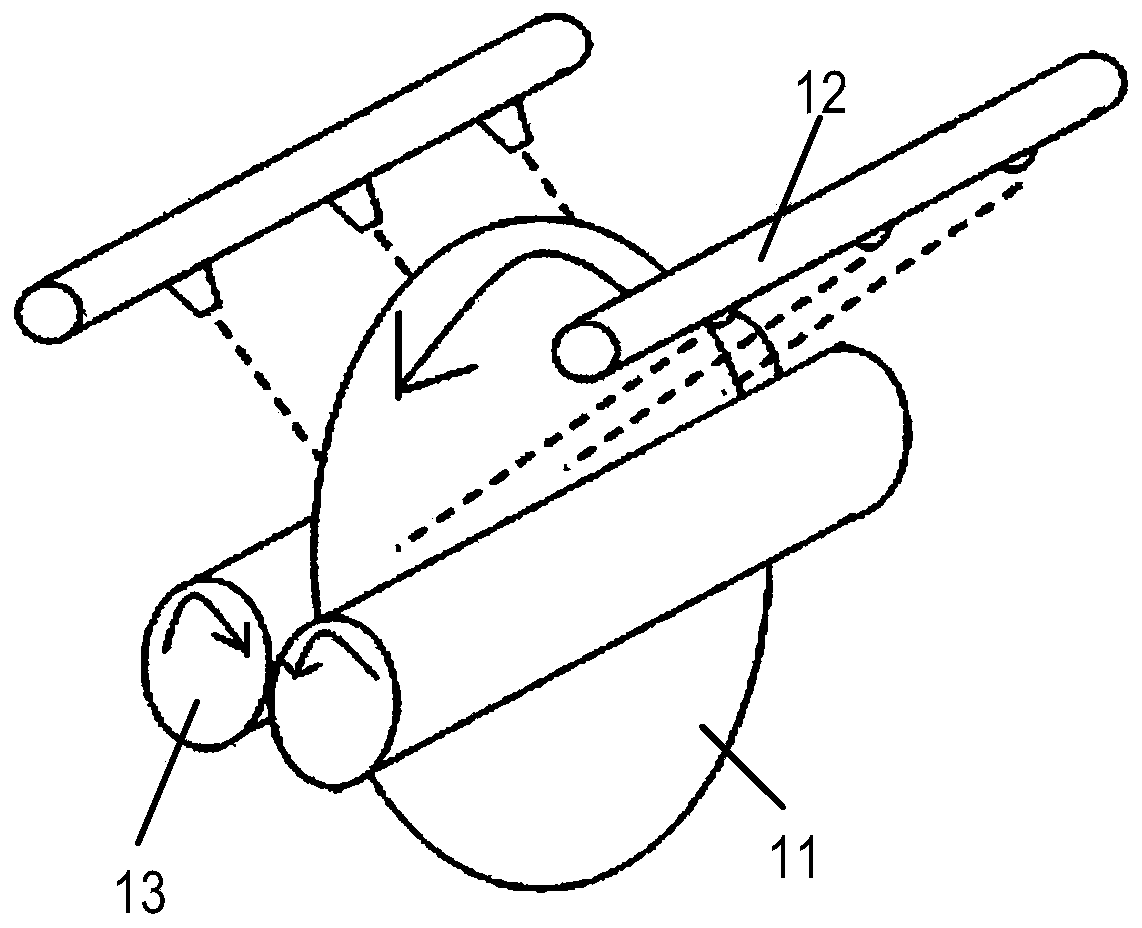

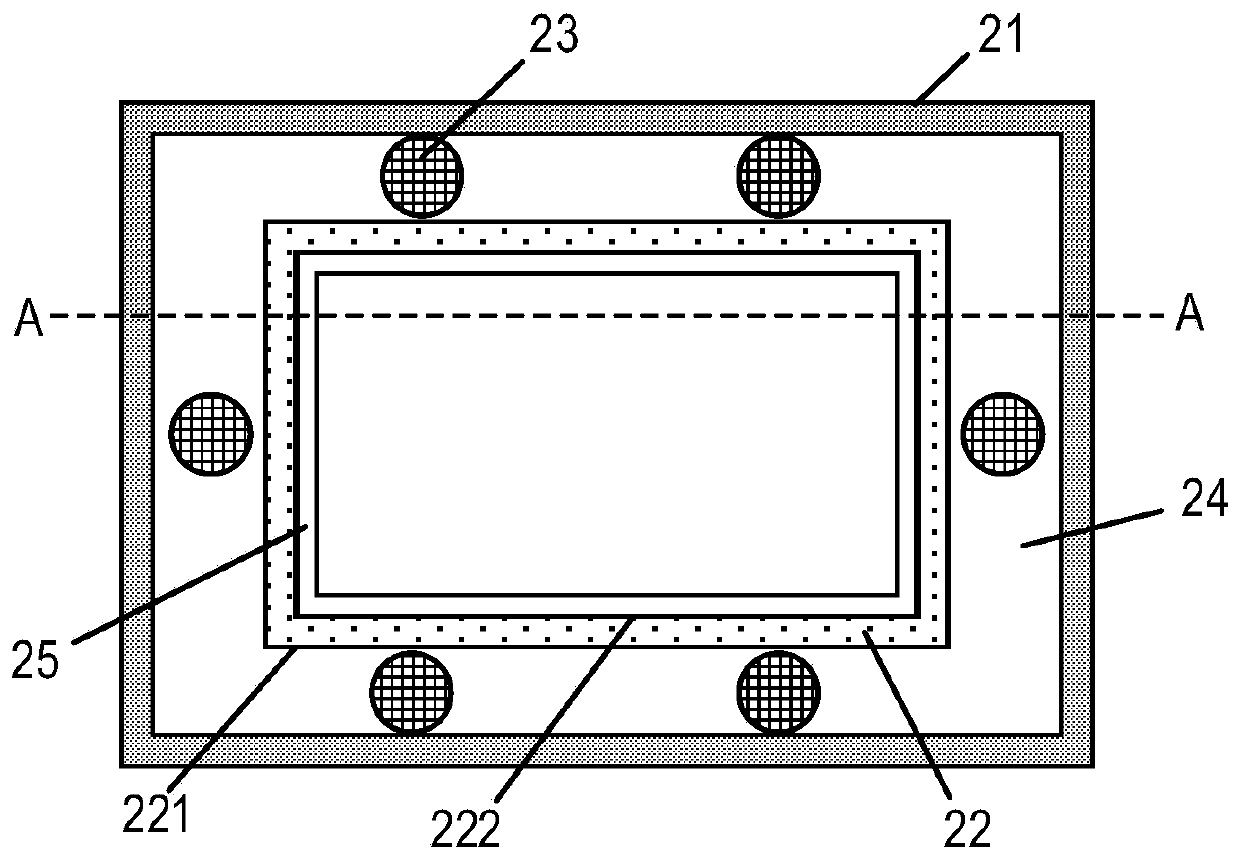

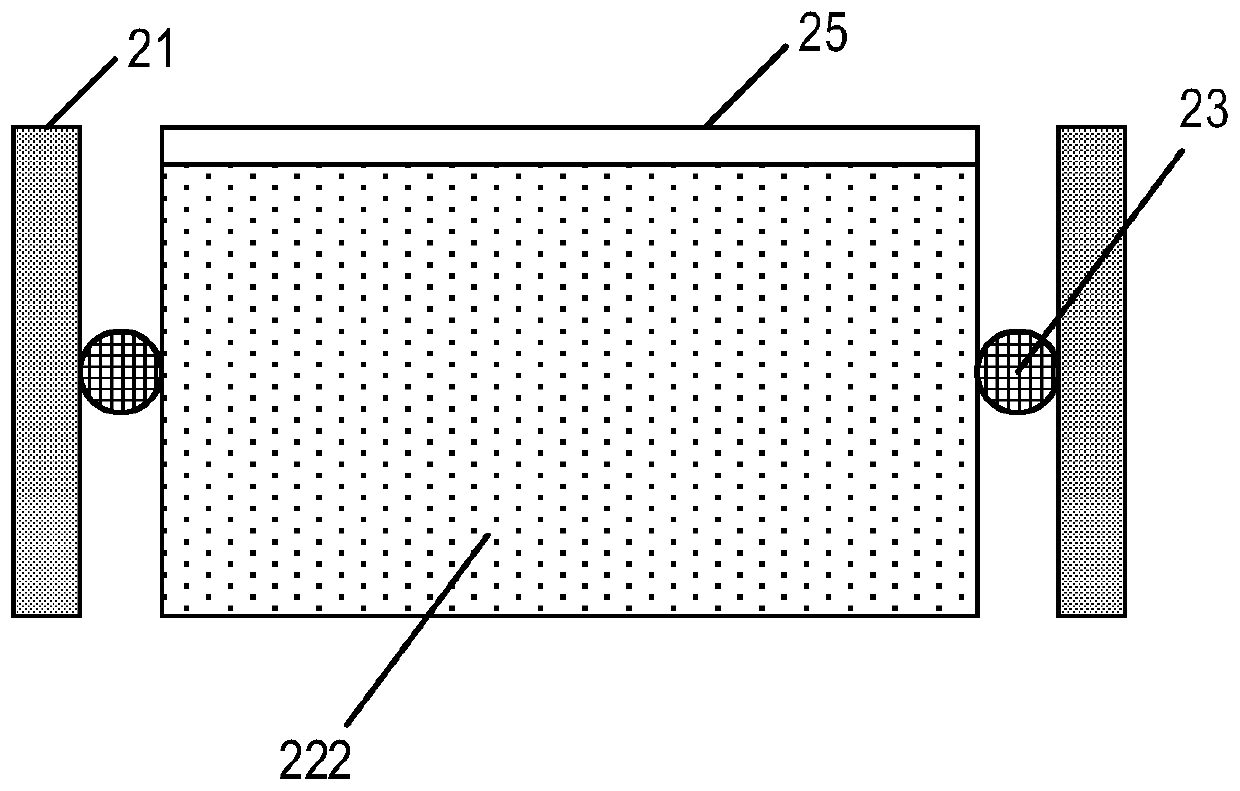

[0024] This specific embodiment provides a cleaning box, with figure 2 It is a top view structure schematic diagram of the cleaning box according to the first specific embodiment of the present invention, with image 3 is attached figure 2 Sectional view along A-A direction. like figure 2 , 3 As shown, the cleaning box provided in this specific embodiment includes a box body, the inner wall of the box is provided with a fluid channel 25, and the cleaning liquid can flow out through the fluid channel 25 to cover the inner surface 222 of the inner wall 22; The inner wall 22 of the box body also includes an interlayer, and at least one ultrasonic transducer 23 is arranged in the interlayer, and the ultrasonic transducer 23 is used to emit ultrasonic waves, and the ultrasonic waves act on the cleaning liquid to realize cleaning. Cleaning of the inner wall 22. In this specific embodiment, the box includes an inner wall 22 and an outer wall 21 , the inner wall 22 forms a waf...

no. 2 Embodiment approach

[0033] This specific embodiment provides a cleaning method for cleaning the inner wall of the box, with Figure 4 It is a flow chart of the cleaning method for cleaning the inner wall of the tank according to the second embodiment of the present invention. like Figure 4 As shown, the cleaning method for the inner wall of the cleaning box described in this specific embodiment includes the following steps:

[0034] Step S31, providing a box body of a cleaning box, the inner wall of the box body is provided with a fluid channel, and the inner wall of the box body also includes an interlayer, and at least one ultrasonic transducer is arranged in the interlayer for emitting ultrasonic waves . In this specific embodiment, the interlayer can be arranged on the side, top or bottom of the inner wall, and those skilled in the art can choose according to actual needs. The following description will be made by taking the interlayer disposed on the side of the inner wall as an example....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com