Phosphor material for near infrared LED and preparation method of phosphor material

A fluorescent powder and near-infrared technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of wide excitation range, simple preparation method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

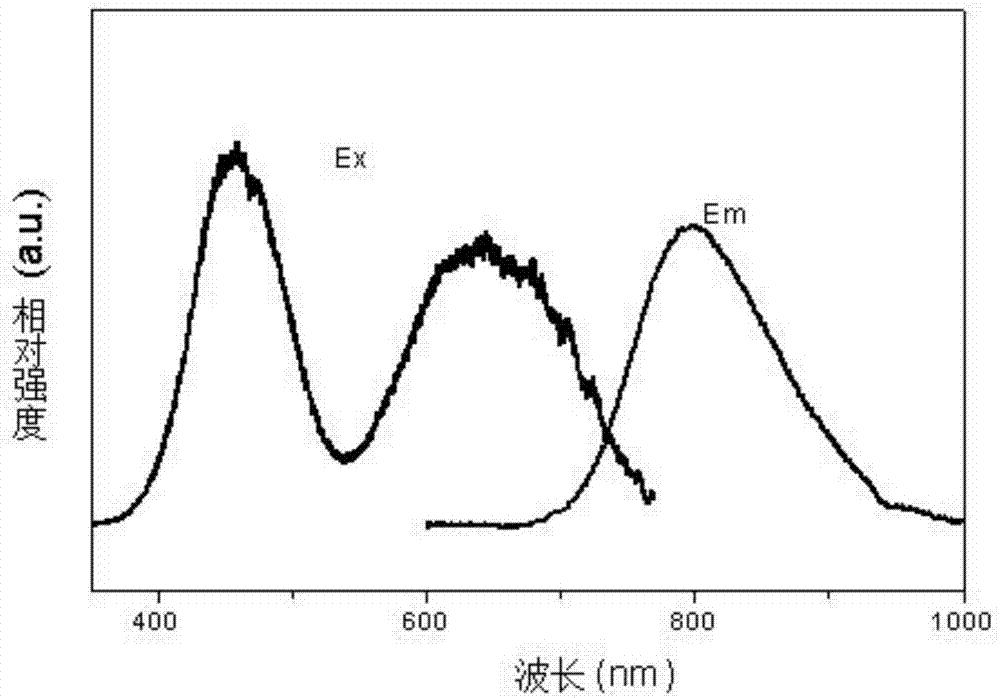

[0028] Weigh raw material Sc 2 o 3 0.025 mol, H 3 BO 3 0.0625 mol, Cr 2 o 3 0.00025 moles. After the raw materials are fully mixed, they are sintered in air at 1300°C for 10h. The resulting product is fully ground, washed three times with deionized water, and dried at 80° C. to obtain the near-infrared fluorescent powder of the present invention. The excitation spectrum and emission spectrum of this embodiment are as attached figure 1 shown.

Embodiment 2

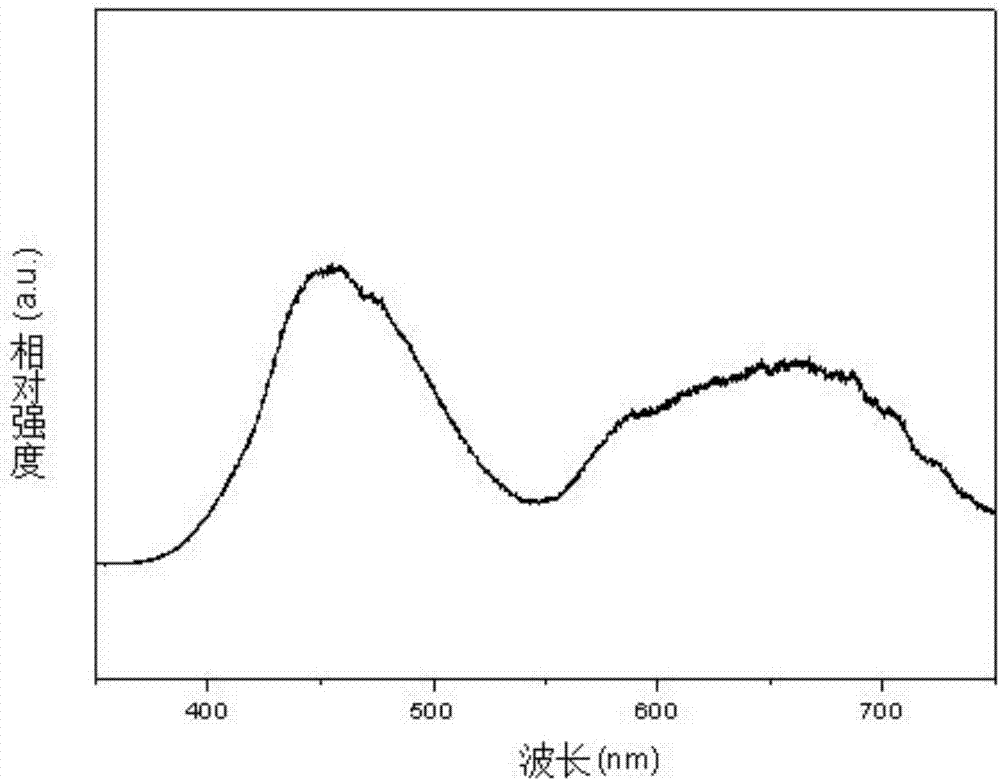

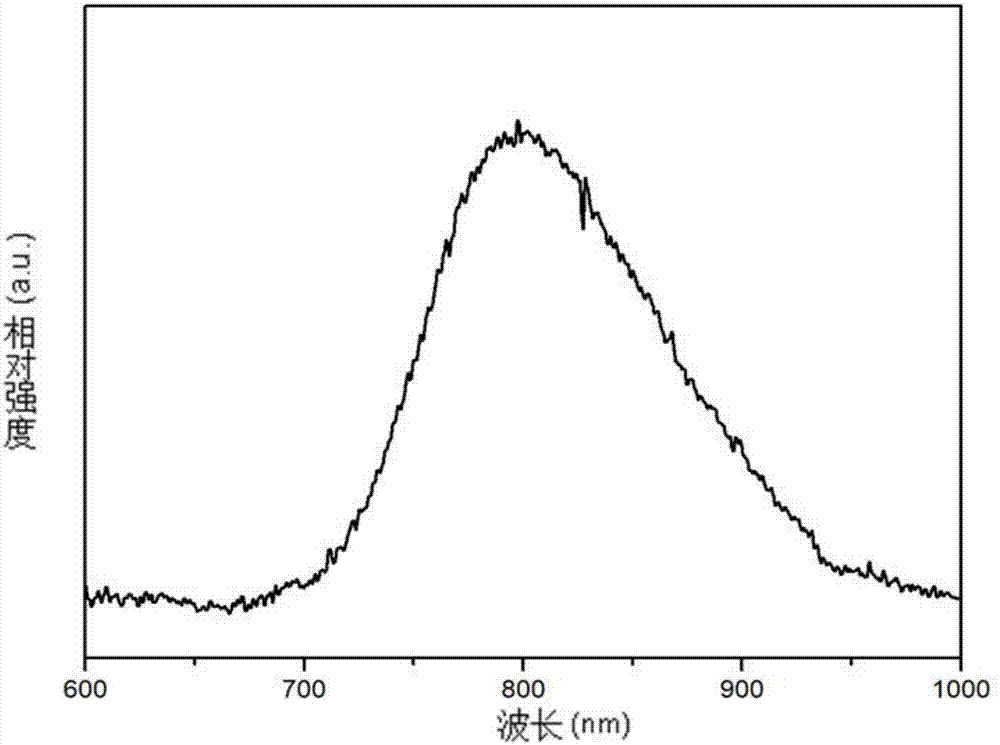

[0030] Weigh raw material Sc 2 o 3 0.025 mol, H 3 BO 3 0.1 mole, Cr 2 o 3 0.00025 mole, weigh 1% BaF of raw material weight 2 as a flux. After fully mixing the raw materials and flux, sinter in air at 1200°C for 5h. After the calcined product is fully ground, it is fired a second time at 1200°C for 10 hours in air. The resulting product is ground, washed three times with deionized water, and dried at 100° C. to obtain the near-infrared fluorescent powder of the present invention. The excitation spectrum and emission spectrum of this embodiment are as attached figure 2 , 3 shown.

Embodiment 3

[0032] Weigh raw material Sc 2 o 3 0.025 mol, H 3 BO 3 0.075 mol, Cr 2 o 3 0.0005 mol, weigh 5% of the raw material weight of BaF 2 as a flux. After fully mixing the raw materials and flux, sinter in air at 1200°C for 20h. After the calcined product is fully ground, it is washed three times with deionized water and dried at 120°C to obtain the near-infrared fluorescent powder of the present invention. The excitation spectrum and emission spectrum of this embodiment are as attached Figure 4 , 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com