Recovery method of pepper oil processing by-product oiled pepper

A technology of oiling pepper and pepper oil, which is applied in food science and other fields, and can solve the problems of discarding and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 Zanthoxylum bungeanum oil and the recovery of over-oiled Zanthoxylum bungeanum

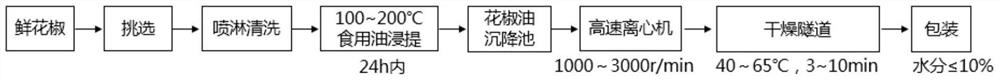

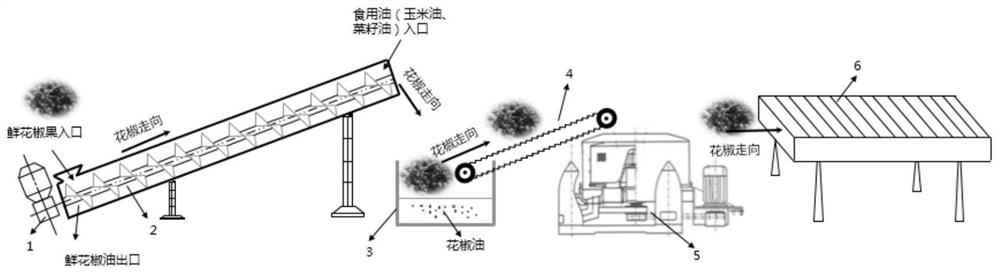

[0045] The specific steps of the method of this embodiment include:

[0046] (1) Fresh Zanthoxylum bungeanum should be picked in sunny days, preferably when there is sunshine, and should not be picked in rainy days or with dew. Fresh Zanthoxylum bungeanum should be used for processing Zanthoxylum bungeanum oil within 24 hours after picking to ensure the color and luster of Zanthoxylum bungeanum oil. pure flavor;

[0047] Fresh peppers are selected to remove moldy and rotten fruits, and then sprayed with water to remove stains, dust and other impurities on the surface of fresh peppers; then, use a high-power fan (power ≥ 2kW) to blow off the residual water on the surface of fresh peppers, so as to facilitate the fresh peppers. Oil immersion extraction; then, short-term hot air drying of most of the water on the surface of fresh peppercorns to obtain washed an...

Embodiment 2

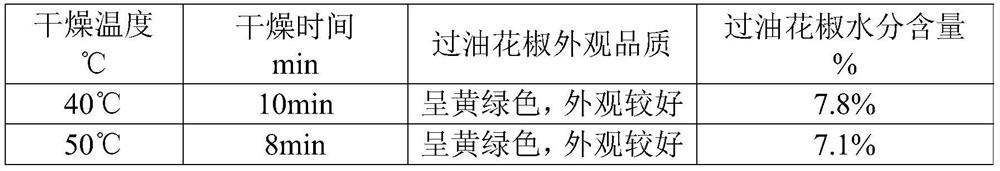

[0052] Embodiment 2 oil temperature condition screening

[0053]Using the method of Example 1, using first-grade rapeseed oil at an oil temperature of 100-200° C., the Chinese prickly ash oil was extracted for 3-15 minutes. According to the sensory evaluation standard of Zanthoxylum bungeanum oil in Table 1 and the sensory evaluation standard of Zanthoxylum bungeanum oil in Table 3, the obtained Zanthoxylum bungeanum oil and Zanthoxylum bungeanum were evaluated and compared respectively.

[0054] Table 1 Sensory evaluation criteria of pepper oil

[0055] index describe Weight KPI, % full marks color Pure and uniform color, natural turquoise 20% 100 transparency Clear and transparent, not turbid, no precipitation 20% 100 odor Has a strong and pure green pepper unique green aroma 30% 100 taste Soft taste, pure numb taste, no bitterness and peculiar smell 30% 100

[0056] Table 2 Evaluation results of Zanthoxylum bungeanum ...

Embodiment 3

[0065] Example 3 Centrifugal condition screening

[0066] Using the method of Example 2, using first-grade rapeseed oil at an oil temperature of 100° C., leaching Zanthoxylum bungeanum oil for 15 minutes, and evaluating and comparing the oiled Zanthoxylum bungeanum obtained under different centrifugation conditions.

[0067] Table 5 Evaluation of the effect of oil-treated Zanthoxylum bungeanum after being centrifuged in a three-legged centrifuge

[0068] Centrifuge speed, r / min Centrifugation time, min Oil content of oily peppercorns, % 1600 3 5.54% 1200 5 5.8% 600 8 6.45%

[0069] It can be seen from the above table 5 that the faster the centrifugal speed of the centrifuge, the better the effect of removing the residual oil on the surface of the oil-treated peppercorns. When the centrifugal speed reaches 1600r / min and 3min, the oil content of the oil-treated peppercorns after centrifugation is 5.54%. The rotating speed is fast, so the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com