Water standing wave shaking table and beneficiation method

A standing wave and bed technology, applied in the field of water standing wave shaking table and mineral processing, can solve the problems of low recovery rate, environmental hazards, wide separation particle size, etc., achieve rapid mineral processing efficiency, ensure mineral processing efficiency, and high mineral processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

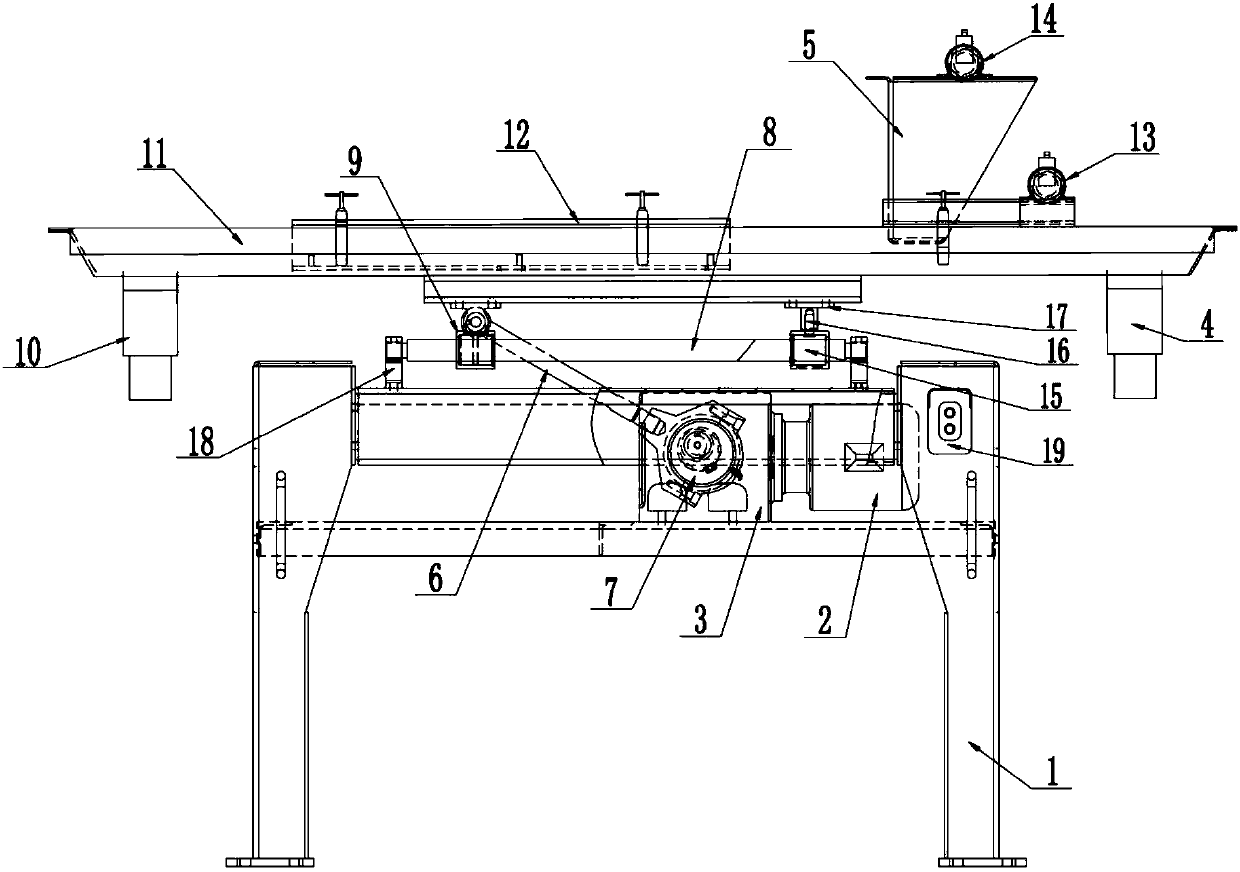

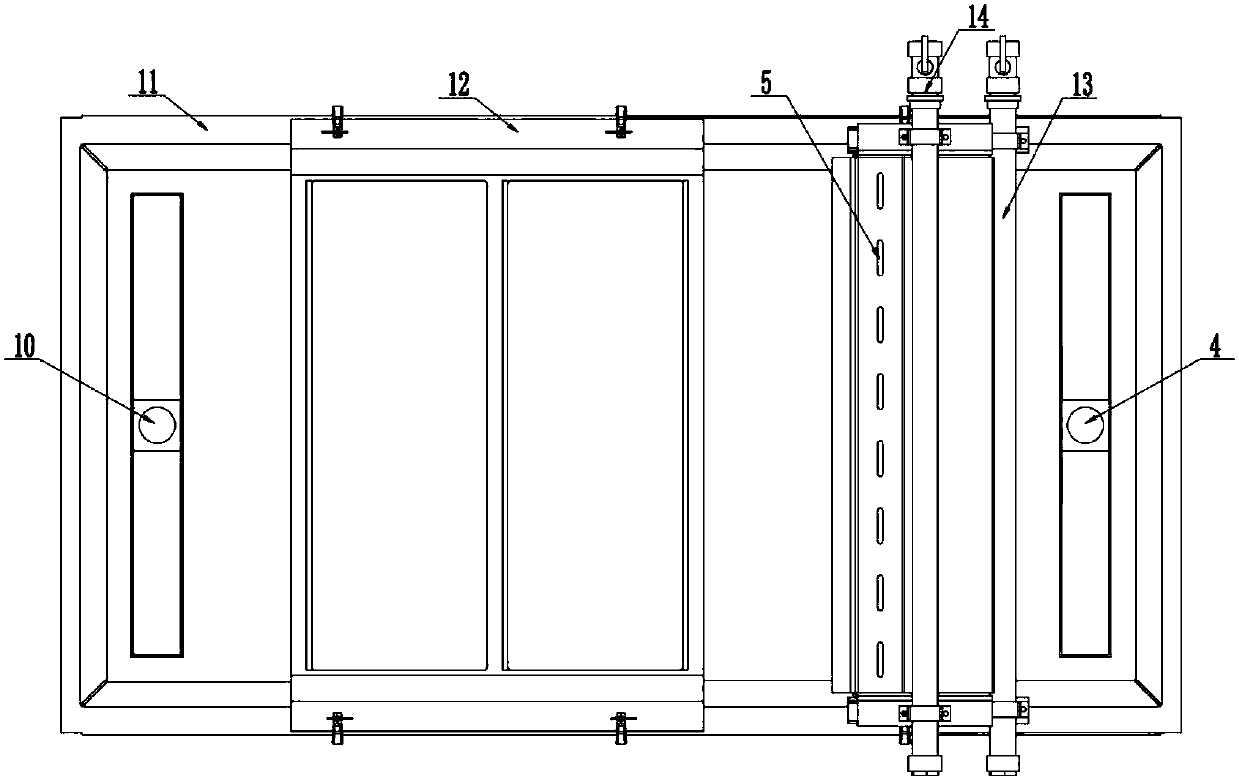

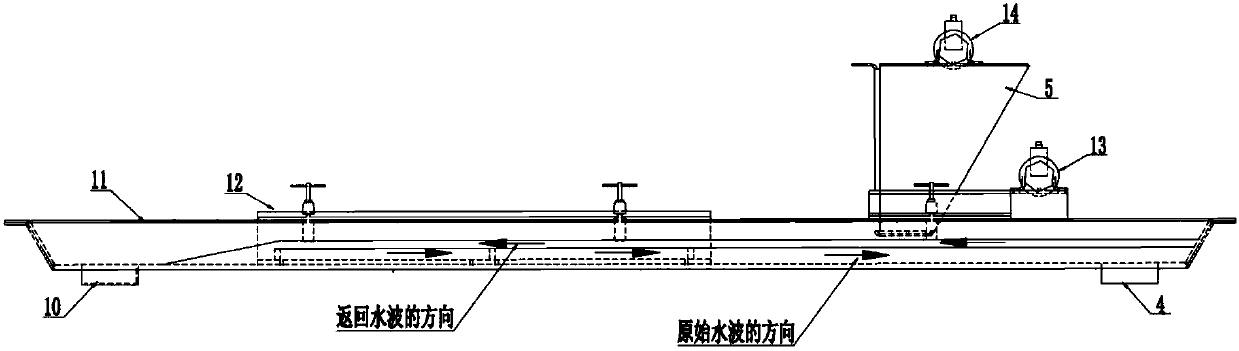

[0032] Such as Figure 1-Figure 3 Shown, a kind of water standing wave shaker, comprise frame 1 and be arranged on the bed support drive mechanism and bed 11 on the frame, the bed is provided with feed tank 5, water pipe 13, precision Mine discharge port 4 and tailings discharge port 10;

[0033] The bed support drive mechanism includes a drive motor 2, a reducer 3, and polished rods 8, active sliding sleeves 9, passive sliding sleeves 15 and deflection mechanisms respectively arranged on both sides of the bed, and the two ends of the polished rods are supported by The seat 18 is fixedly connected with the frame, the active sliding sleeve 9 and the passive sliding sleeve 15 are slidably fitted on the outside of the polished rod, the top of the activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com