Linear drive high-speed press

A technology of linear drive and press, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of limited tonnage of presses, permanent magnets are easily damaged, and output thrust is small, so as to reduce material consumption and cost, and achieve great development Application potential, effect of increasing stamping force tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

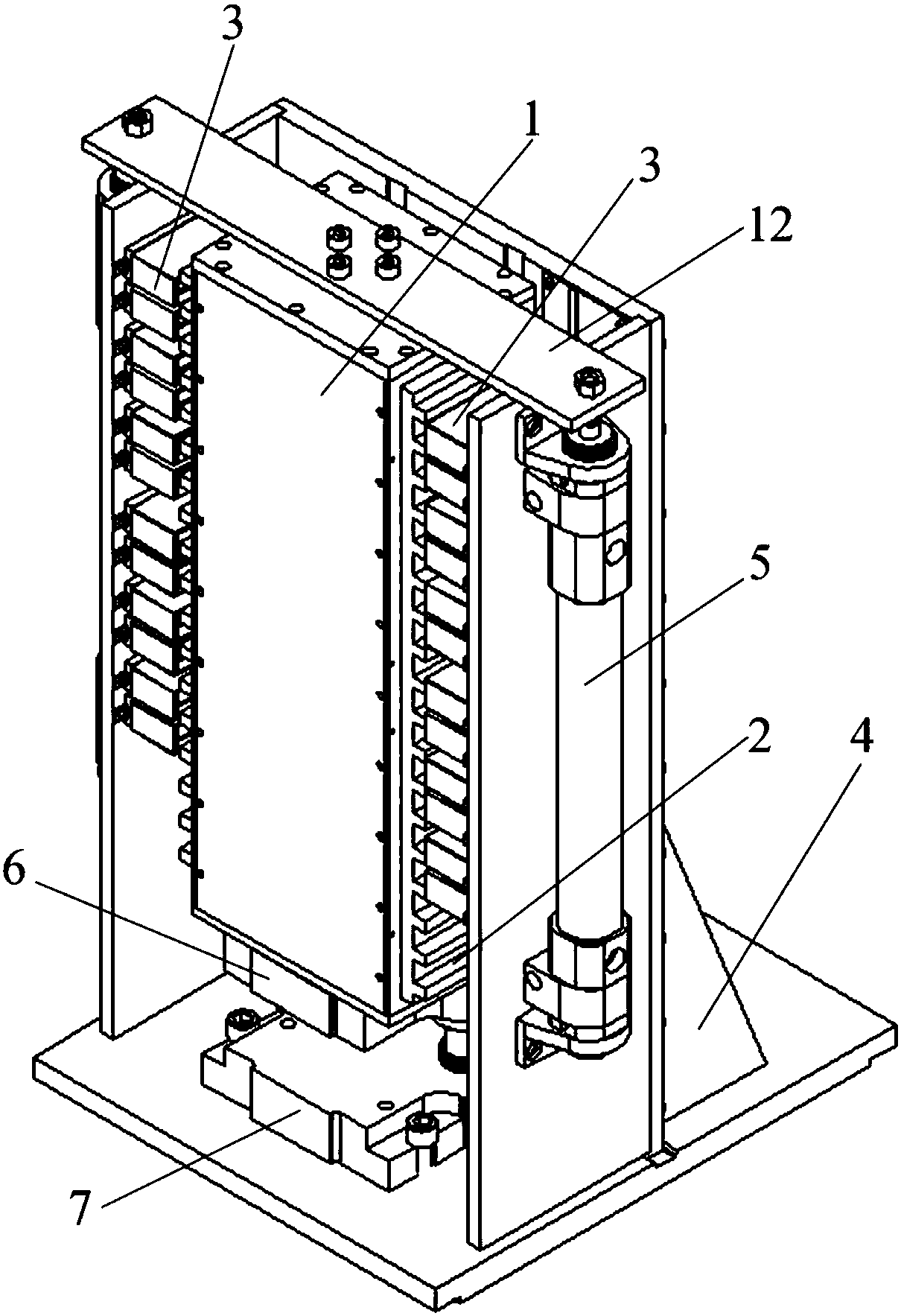

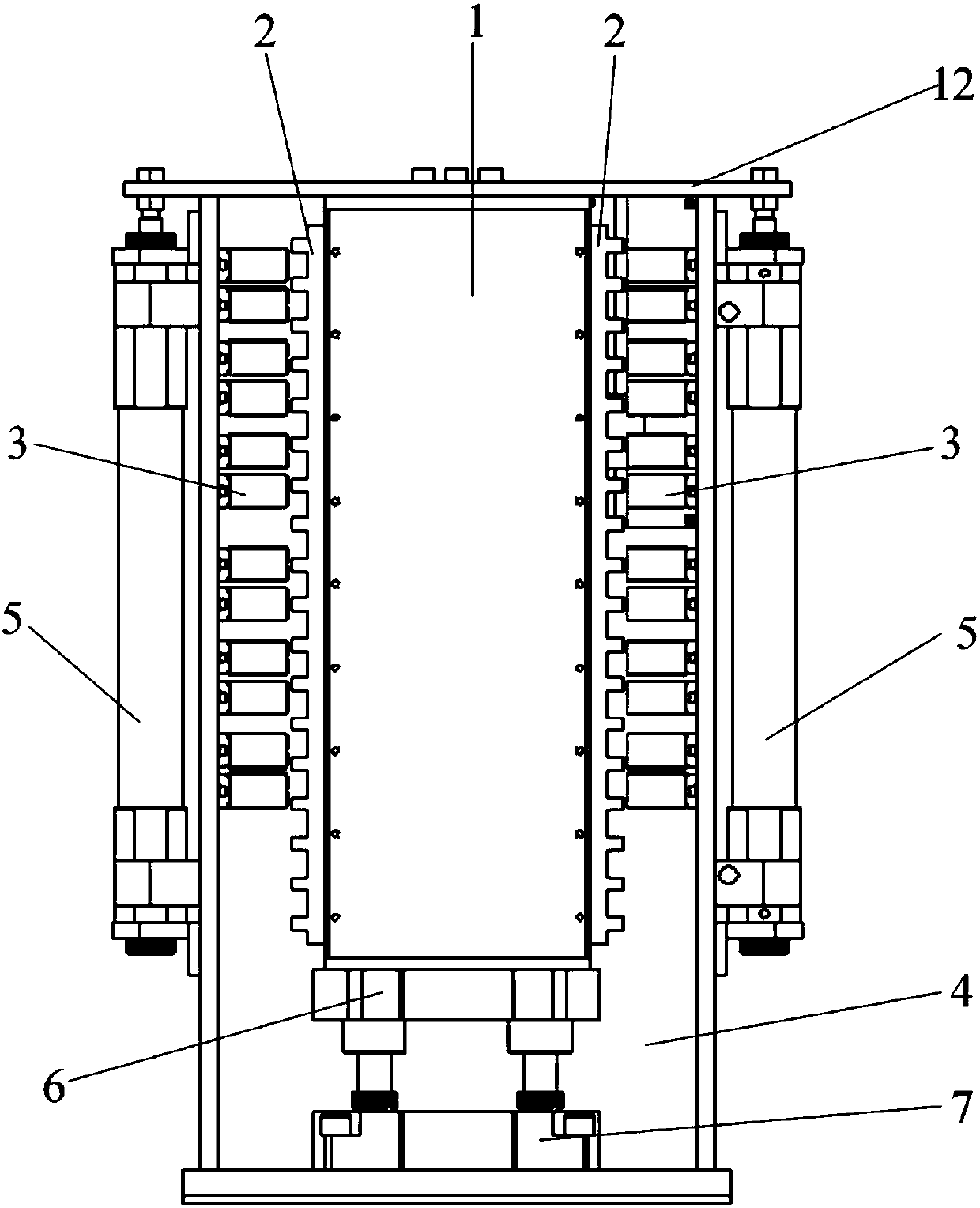

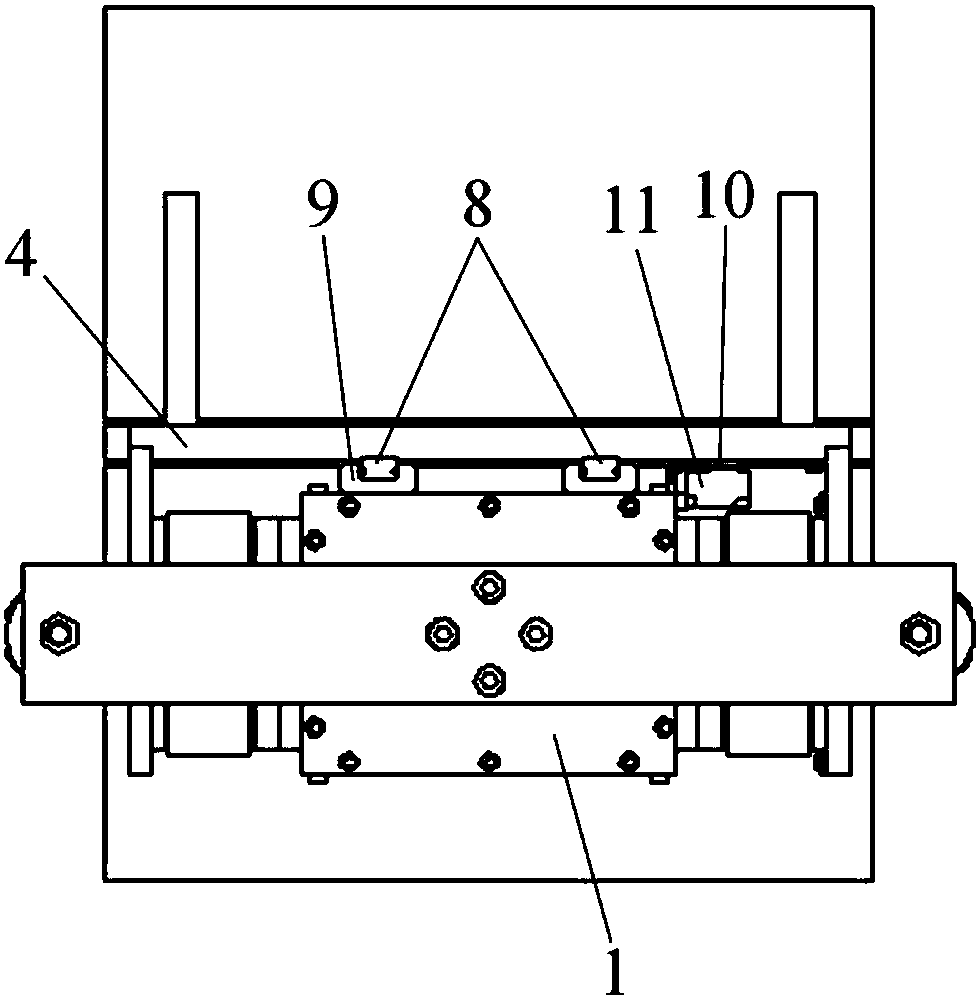

[0028] The composition and structure of a high-speed press driven by a cylindrical stator permanent magnet linear motor of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0029] combine figure 1 with figure 2 As shown, the present invention is a linear drive high-speed press, and its components include a punch 1, a linear motor secondary 2, a linear motor primary module 3, a body 4, a cylinder 5, an upper mold frame 6, a lower mold frame 7, Guide rail 8, slider 9, grating ruler 10, grating reading head 11 and connecting plate 12, the press machine is an open structure, and the punch 1 is a cuboid structure. The switched flux linear motor has a flat structure, and the secondary 2 of the linear motor and several linear motor primary modules 3 form a single-sided flat switched flux permanent magnet linear motor. The left and right sides of the punch 1 are respectively symmetrically provided with a unilateral plate-type s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com