Color printing film plastic woven barrel material bag composite automatic benchmarking device

A technology of color printing film and plastic weaving, applied in lamination devices, lamination auxiliary operations, chemical instruments and methods, etc., to achieve the effects of improving product quality, increasing automation, and reducing physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiment is further described in detail below in conjunction with accompanying drawing:

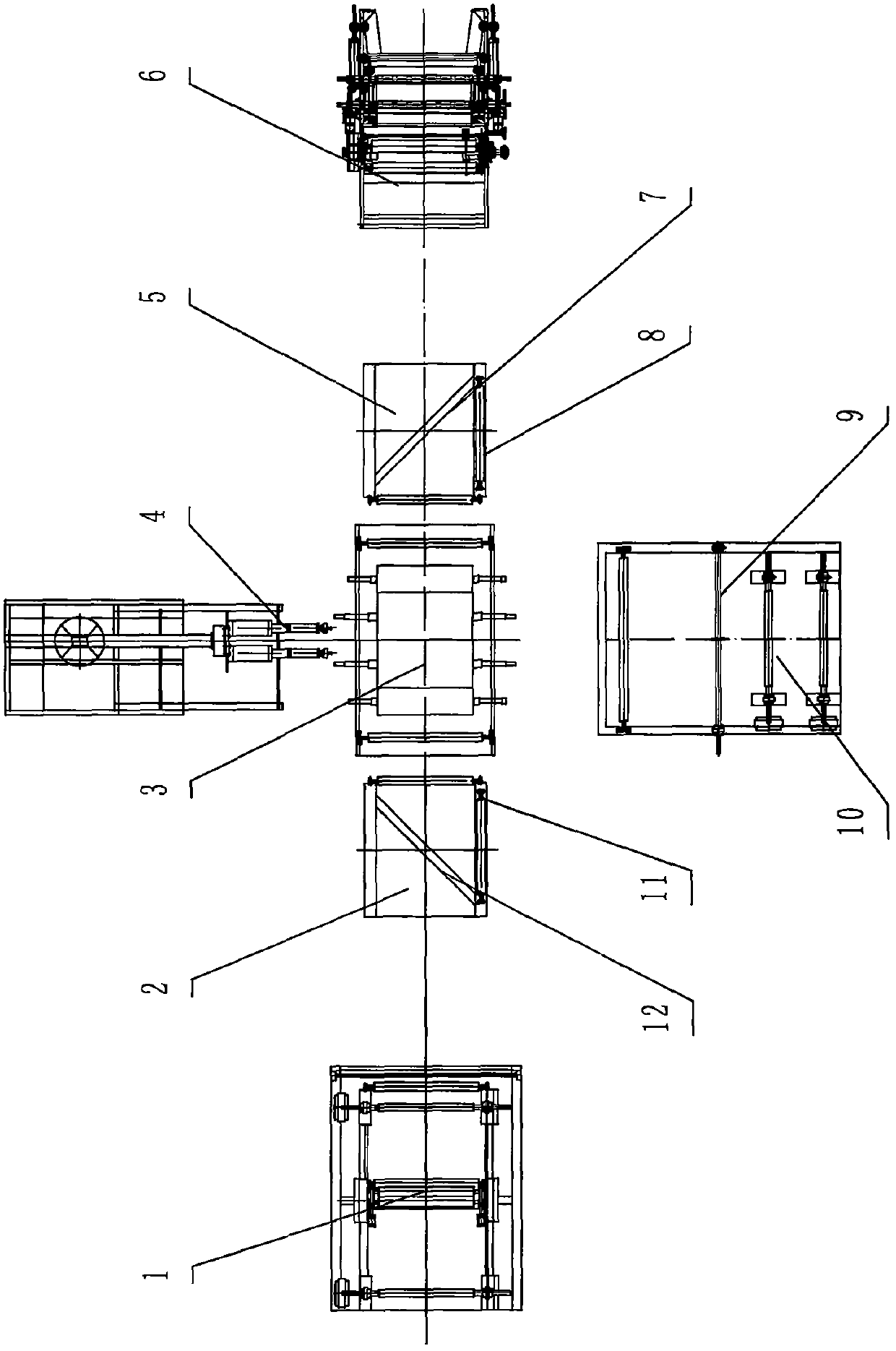

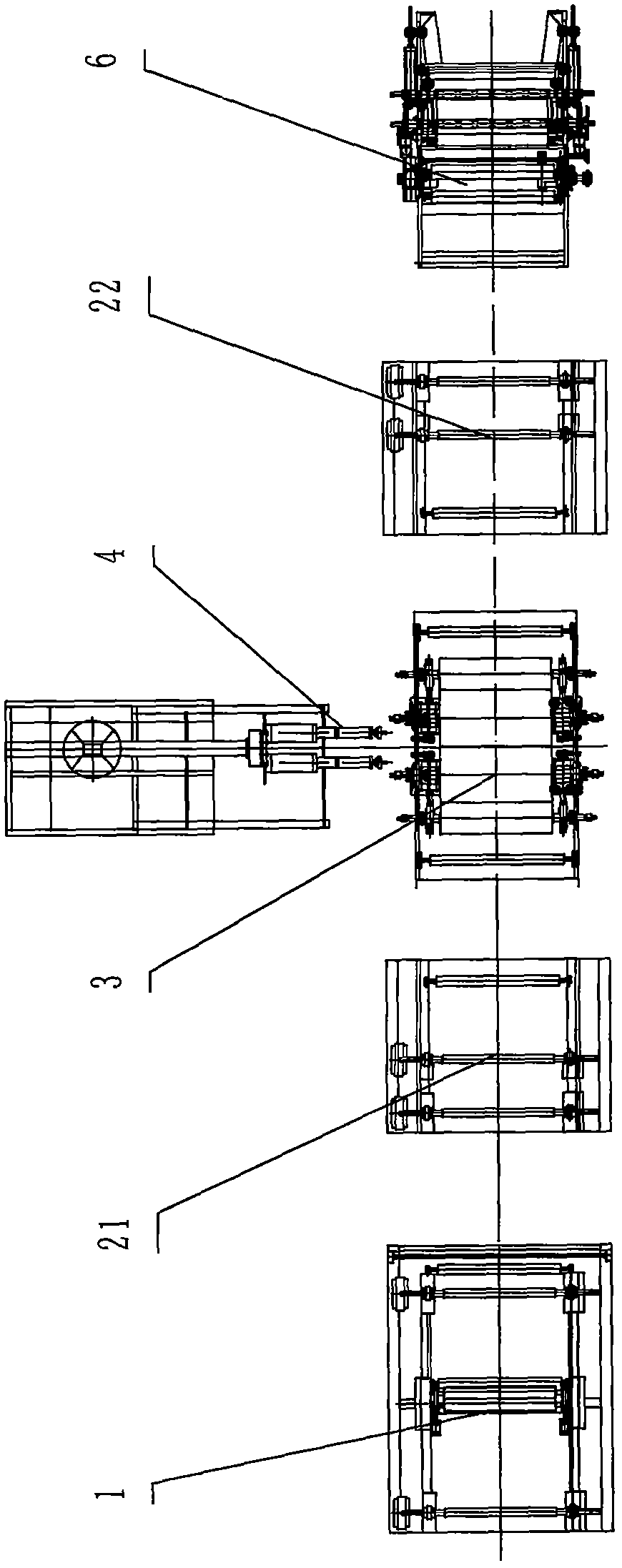

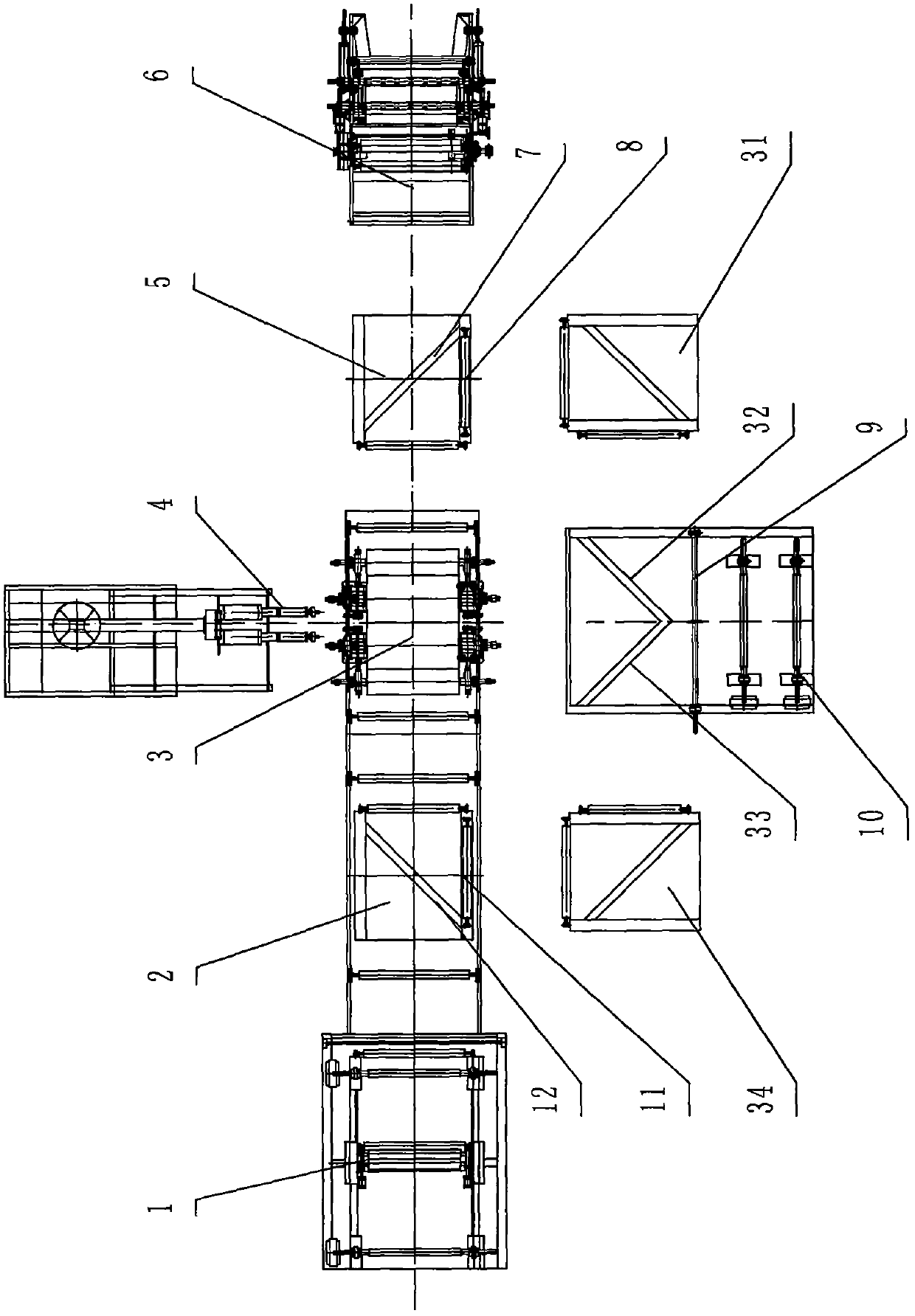

[0011] refer to figure 1 : 1-Plastic woven tube bag unwinding device, 2-A turning film guiding device, 3-composite pressure roller device, 4-plastic extrusion double die head, 5-B turning film guiding device, 6-color printing film plastic weaving Bag winding device, 7-B triangular film guide, 8-B guide roller, 9-divider, 10-color printing film unwinding frame, 11-A guide roller, 12-A triangular film guide, in the figure: color printing Composite automatic benchmarking device for film-plastic woven cylinder bags. The arrangement of each equipment is in the longitudinal direction, there are plastic woven cylinder material bag unwinding device 1, A turning film guiding device 2, composite pressing roller device 3, B turning film guiding device 5 , the color printing film plastic woven bag rewinding device 6, the plastic extrusion double die head 4, the divider 9 and the color prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com