Intelligent truck loading system

An intelligent, conveyor belt technology, which is applied in the directions of transportation and packaging, loading/unloading, object stacking, etc., can solve problems such as high energy consumption, impact on efficiency, and damage to the surface of goods, and achieve strong system compatibility, compact overall design, and energy saving The effect of business costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

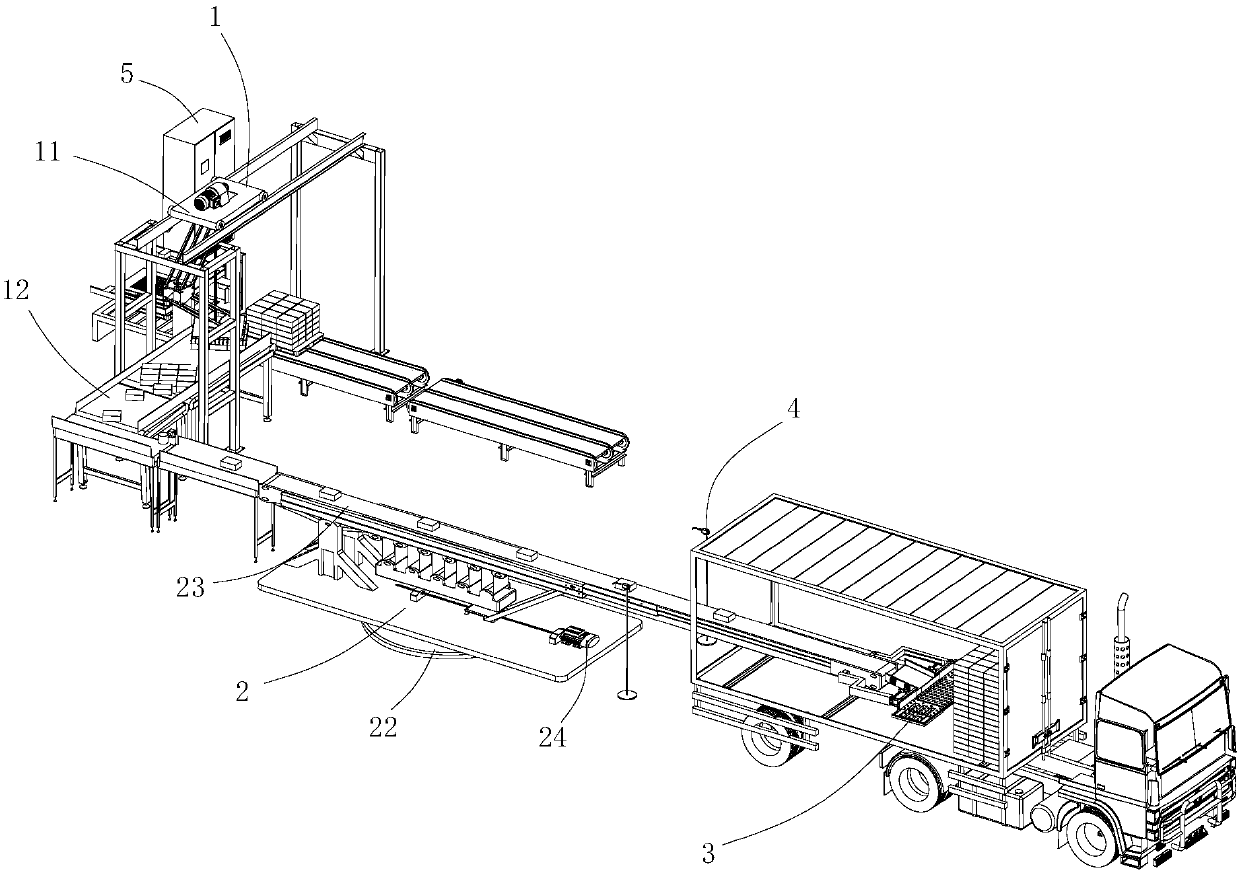

[0041] This embodiment provides an intelligent loading system, such as figure 1 As shown in -7, it includes a destacking device 1, a long-arm robot 2, a fixture 3, a visual positioning device 4, and a control device 5.

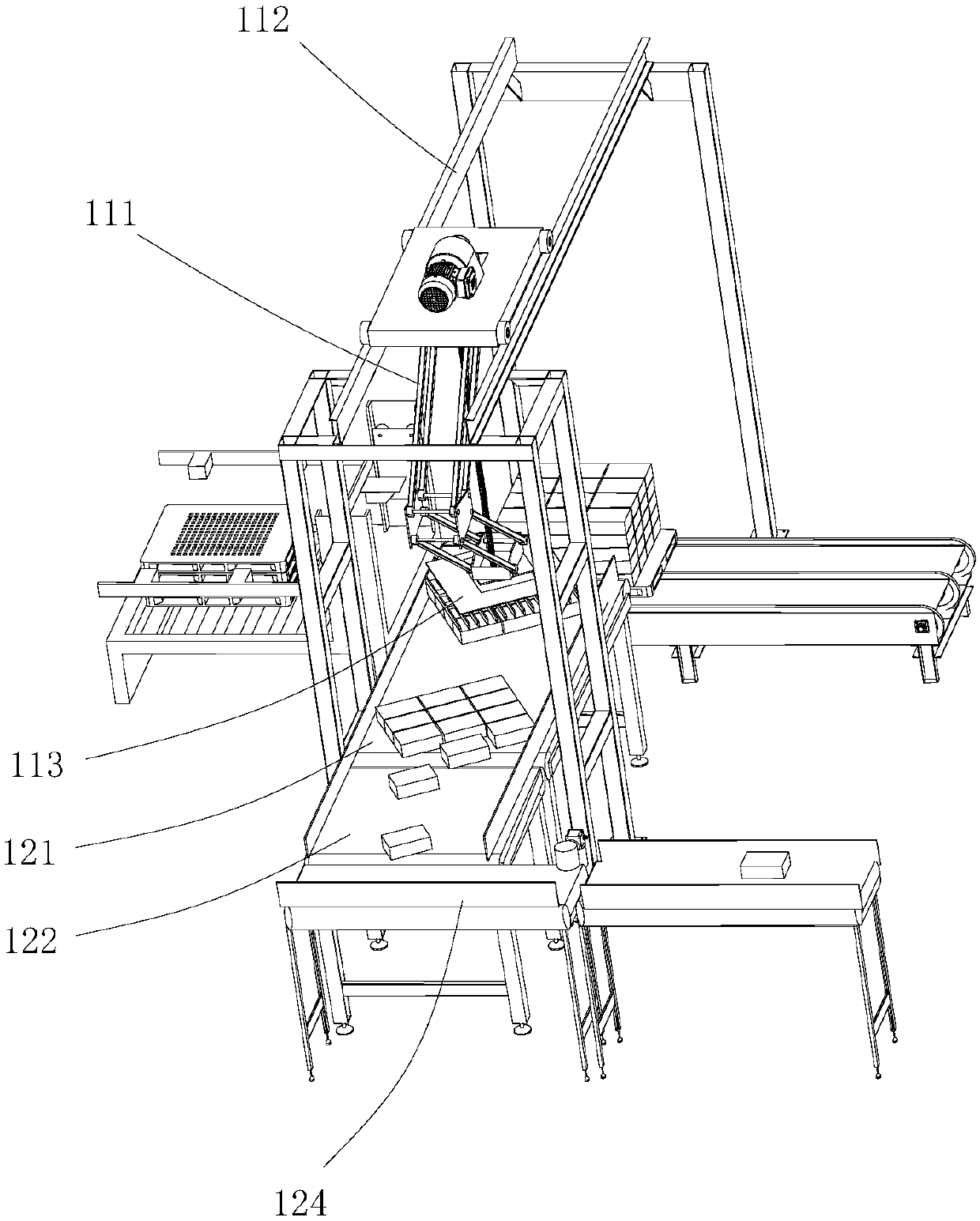

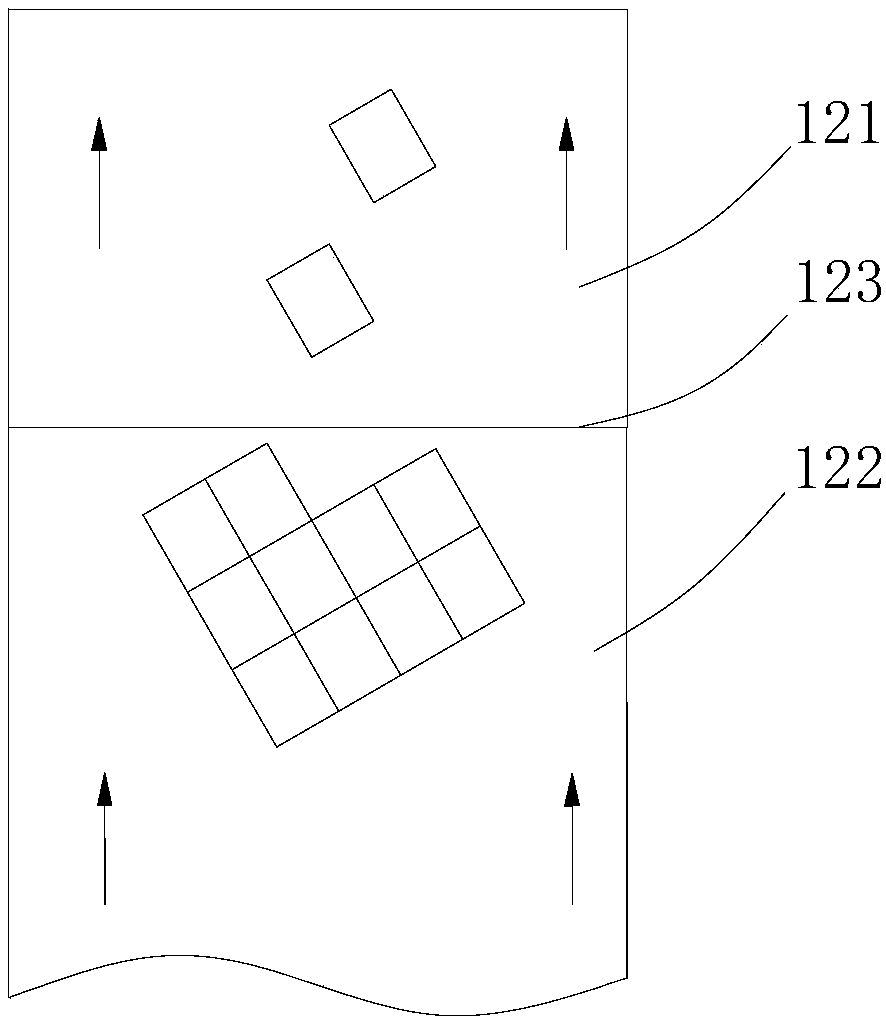

[0042] Wherein, destacking device 1, such as figure 2 As shown, it comprises unstacking robot 11, sub-box mechanism 12, and sub-box mechanism 12 comprises the first conveyor belt 121, the second conveyor belt 122 that are connected successively, and the speed of the first conveyor belt 121 is lower than the speed 122 of the second conveyor belt; The stacking robot 11 picks up the entire layer of goods, and the unstacking robot 11 includes an unstacking mechanical arm 111, a sliding support 112, and a vacuum suction cup 113 arranged at the working end of the unstacking mechanical arm 111. Vacuum up the entire layer of cargo. The unstacking mechanical arm 111 rotates the entire layer of goods at a certain angle, which is matched with the boundary line, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com