Device and method for enhancing heat and mass transfer for superheated steam drying of sludge

A technology of superheated steam, heat and mass transfer, applied in chemical instruments and methods, dehydration/drying/thickened sludge treatment, mixer with rotating stirring device, etc., can solve insufficient contact, low sludge drying rate, Affect the drying effect and other issues, to achieve the effect of increasing the number and frequency of exercise, improving heat and mass transfer effect, and improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

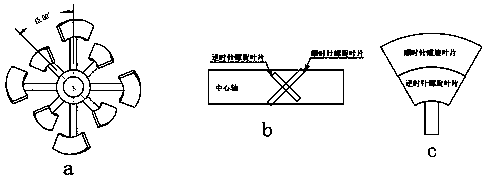

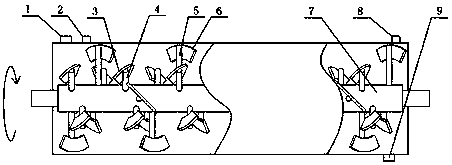

[0033] Such as figure 1 The shown sludge superheated steam drying heat and mass transfer enhancement device includes feed inlet 1, air outlet 2, counterclockwise spiral blade 3, counterclockwise spiral blade support column 4, clockwise spiral blade support column 5, and clockwise spiral blade support column. Blade 6, central axis 7, air inlet 8 and discharge port 9.

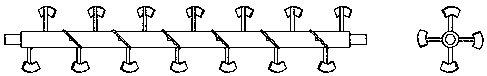

[0034] Such as figure 2 The clockwise spiral blade 6 is arranged from the feed port 1 to the discharge port 9, and forms a clockwise spiral blade around the central axis 7. The clockwise spiral blade 6 is welded to the clockwise spiral blade support column 5 connected, and the axial angles between each blade and the central axis 7 are the same, and the clockwise spiral blade support columns 5 are arranged every 90°, and are welded on the central axis 7.

[0035] Such as image 3The counterclockwise s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com