Modified conjugated diene polymer and its preparation method and styrene-butadiene rubber

A conjugated diene and polymer technology, applied in the field of rubber modifiers, can solve the problems of reducing the cold flow of rubber, increasing the damping value, inapplicability, etc., and achieving the effect of good rubber storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of a modified conjugated diene polymer, the method comprising:

[0042] (1) Under an inert atmosphere, in an organic solvent, and in the presence of an organolithium initiator, the conjugated diene is subjected to anionic polymerization;

[0043] (2) In the presence of a free radical initiator, the reaction product obtained in step (1) and a modifying agent are subjected to a contact reaction to obtain a modified conjugated diene polymer;

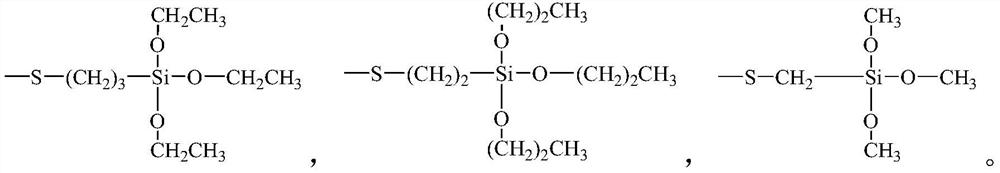

[0044] Wherein, the modifying agent is selected from formula (2) One or more mercapto-containing compounds in HS-R-OH and HS-R-COOH, R 1 -R 3 each independently for C 1 -C 10 Alkyl and C 1 -C 10 The alkoxyl group, R 4 for C 1 -C 20 Alkylene; R is C 1 -C 10 Alkylene, C 3 -C 10 Cycloalkylene, C 6 -C 12 the arylene group;

[0045] The conjugated diene is selected from C 4 -C 8 Conjugated dienes;

[0046] The number average molecular weight of the modified conju...

preparation example 1

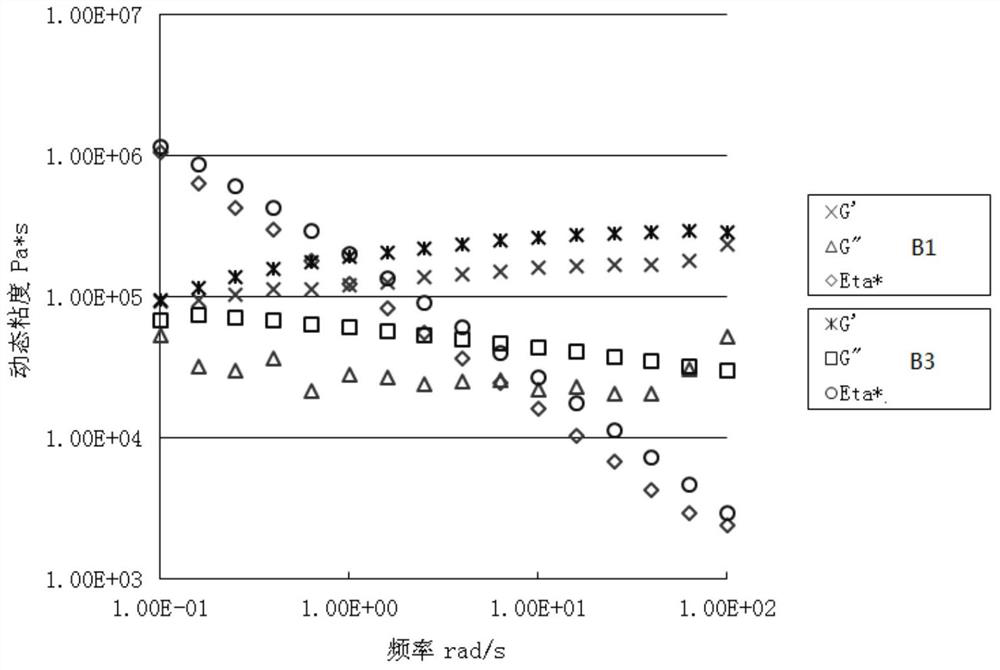

[0085] Under the protection of high-purity nitrogen, 2300g of cyclohexane, 62.4g of styrene and 249.6g of butadiene were mixed, then 1250mg of tetrahydrofurfuryl alcohol ethyl ether was added, and 115mg of n-butyllithium was added at 50°C to initiate, and at 50 React at ℃ for 60 minutes. After the end, take half of the weight of the glue as the base liquid of styrene-butadiene rubber A1, and the remaining glue is condensed by water vapor to obtain the styrene-butadiene rubber sample B1.

preparation example 2

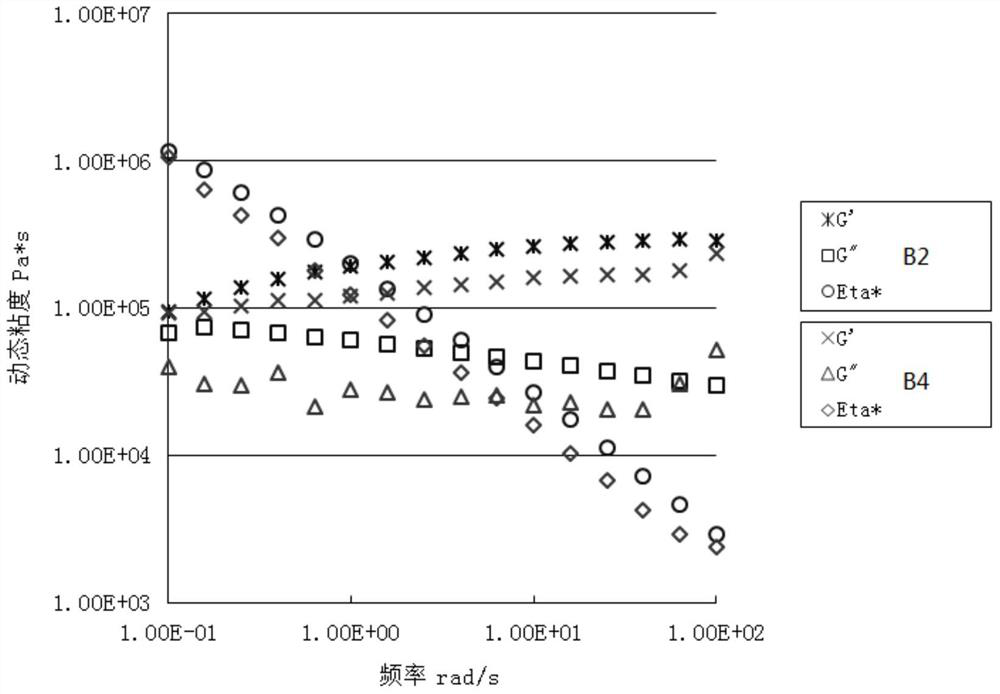

[0087] Under the protection of high-purity nitrogen, mix 2300g of cyclohexane, 62.5g of styrene, 117.6g of isoprene and 127.9g of butadiene, then add 700mg of tetrahydrofurfuryl butyl ether, and add 164mg of n- Initiated by butyllithium, react at 60°C for 60 minutes, then add 67mg of tin tetrachloride, react at 60°C for 20 minutes, after the end, take part of half the weight of the glue as the base liquid of styrene-butadiene rubber A2, and the remaining glue After the liquid was condensed by water vapor, the styrene-butadiene rubber sample B2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| coupling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com