A kind of method of vegetable oil degumming

A vegetable oil and degumming technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of long precipitation and separation time of hydrated oil feet, high cost of membrane, affecting equipment processing capacity, etc., and achieve low degumming operation temperature and long separation time Short, easy-rinse finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

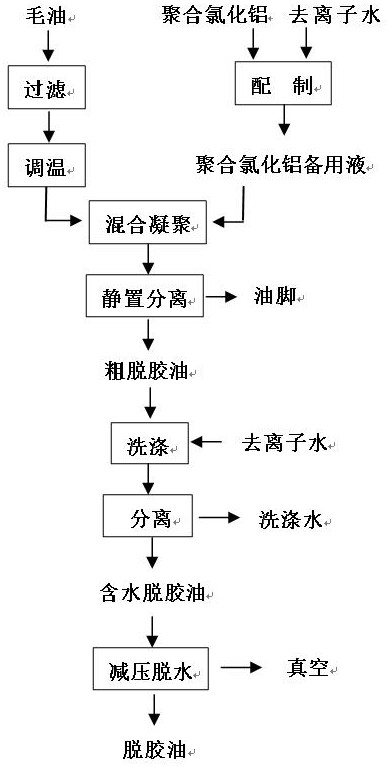

[0033]Seefigure 1The method for degumming the vegetable oil includes the following steps:

[0034](1) Use deionized water to dilute food-grade polyaluminum chloride to a solution with a volume percentage concentration of 0.8%-5%, preferably 1% for use.

[0035](2) Pump the crude rapeseed oil filtered to remove mechanical impurities into the degumming tank, adjust the temperature to 30°C-80°C, preferably 40°C, then add 1% polyaluminum chloride solution, the amount of polyaluminum chloride solution added 1%-5% of the oil weight, preferably 3%-4%, more preferably 4%, stir for 5min-10min to fully mix;

[0036](3) Put the crude oil added with polyaluminum chloride solution to stand, let the colloid in the crude oil fully condense to form larger colloidal particles, so as to facilitate the adsorption of mechanical impurities in the crude oil and sedimentation and separation; After 4h, preferably 3h, the oil feet (gummy) are discharged from the bottom of the degumming tank, or a disc separator or a...

Embodiment 2

[0040]Seefigure 1, The vegetable oil degumming method includes the following steps:

[0041](1) Use deionized water to dilute food-grade polyaluminum chloride to a solution with a volume percentage concentration of 0.8%-5%, preferably 1% for use.

[0042](2) Pump the Camellia oleifera seed oil filtered to remove mechanical impurities into the degumming tank, adjust the temperature to 30℃-80℃, preferably 40℃, and then add 1%-5% polyaluminum chloride solution, preferably 2% -3%, more preferably 2%, stir well for 5min~10min;

[0043](3) Put the tea seed oil added with polyaluminum chloride solution to stand, let the gum in the crude oil fully aggregate to form larger colloidal particles, so as to facilitate the adsorption of mechanical impurities in the crude oil and sedimentation and separation; let stand 1 After -4h, preferably 3h, the oil feet (gummy) are released from the bottom of the degumming tank, or a disc separator or a horizontal screw discharge centrifuge can be used to separate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com