Drum-type chain roller and production technology thereof

A kind of manufacturing process, waist-drum-shaped technology, applied in the field of waist-drum-shaped chain roller and its manufacturing process, can solve the problems such as difficulty in meeting the quality requirements of roller parts, achieve the goal of reducing service life, improving stress state, and increasing high-speed bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

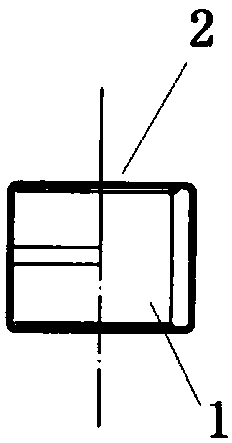

[0019] Example 1: A waist drum-shaped chain roller, as attached figure 1 As shown, the roller body 1 is included, and the middle of the shaft of the roller body 1 has a waist-drum-shaped protrusion 2 of 0.01 mm (this size refers to the distance from the highest point of the waist-drum-shaped protrusion to the level of the shaft).

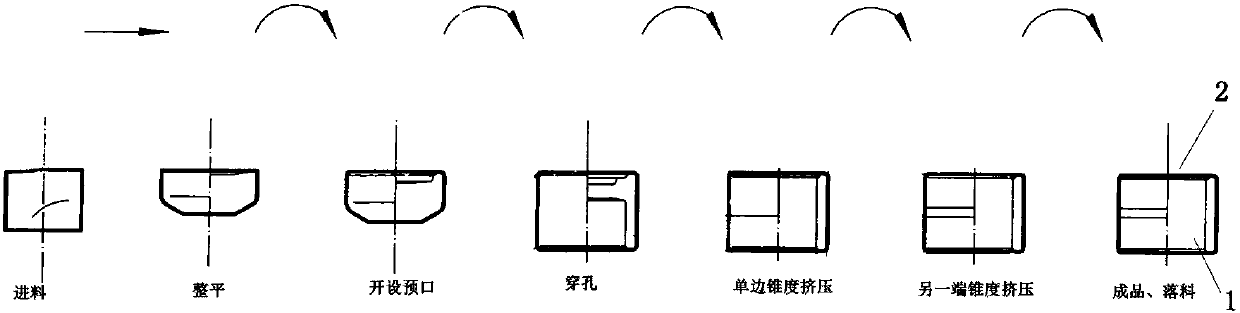

[0020] The manufacturing process of the drum-shaped chain roller, as attached figure 2 As shown, including the following steps;

[0021] a. Feed the round steel bar, cut it to obtain the roller blank, and level the end of the roller blank;

[0022] b. Open a 1.5mm deep pre-port at the end of the roller blank (the pre-port can be a blind hole milled out to prepare for the subsequent perforation), and then the roller blank is positively squeezed and stretched. An extrusion cavity is formed inside the blank;

[0023] c. Perforate the roller blank to remove the waste in the roller blank;

[0024] d. Place one end of the roller blank in a conical die, and use ...

Embodiment 2

[0027] Embodiment 2: A waist drum-shaped chain roller, comprising a roller body, the middle of the roller body has a waist drum-like protrusion of 0.02 mm.

[0028] The manufacturing process of the drum-shaped chain roller includes the following steps;

[0029] a. Feed the round steel bar, cut it to obtain the roller blank, and level the end of the roller blank;

[0030] b. A 2mm-deep pre-port is opened at the end of the roller blank, and then the roller blank is positively squeezed and stretched to form an extrusion cavity inside the roller blank;

[0031] c. Perforate the roller blank to remove the waste in the roller blank;

[0032] d. Place one end of the roller blank in a conical die, and use a punching rod on the other end for unilateral taper extrusion;

[0033] e. Rotate the roller blank, and perform unilateral taper extrusion on the other end of the roller blank to form a 0.02mm waist-drum protrusion in the middle of the roller blank;

[0034] f. Straighten and squeeze the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com