Weight method-based ore pulp concentration meter

A densitometer and gravimetric technology, applied in the field of measuring devices for detecting fluid concentration, can solve the problems of easy caking and clogging of measuring equipment, unusable use, affecting the process process, etc., to avoid easy deposition and caking, and prevent clogging. Significant, increased measurement frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

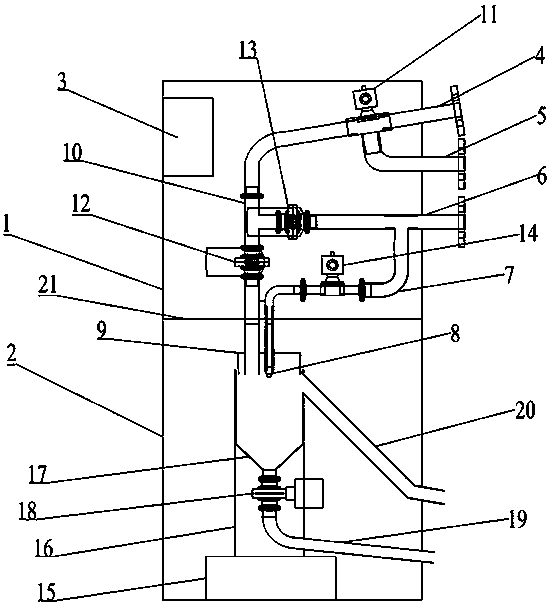

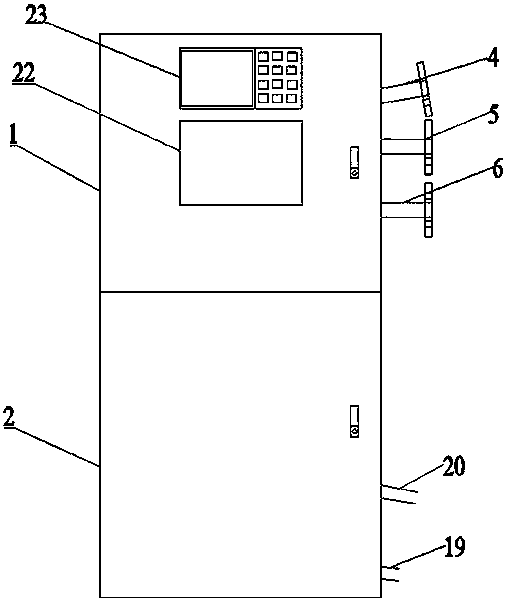

[0027] Such as figure 1 and figure 2 A slurry concentration meter based on the specific gravity method shown includes an upper box body 1, a lower box body 2, a liquid inlet cleaning structure arranged in the upper box body, a circuit control board 3 and a control display screen assembly 23, which are arranged in the lower box body. The weighing and measuring structure in the box body 2, the liquid inlet cleaning structure includes a liquid inlet pipe 4, a circulation pipe 5, a flushing main pipe 6 and a flushing branch pipe 7; the liquid inlet pipe 4 is sequentially provided with an automatic three-way valve 11, The flushing main pipe access section 10, the first electric valve 12, the circulation pipe 5 is connected to the liquid inlet pipe 4 through the automatic three-way valve 11; the flushing main pipe 6 passes through the second electric valve 13 and the flushing on the liquid inlet pipe 4 The connecting section 10 of the main pipe is connected, and the connection bet...

Embodiment 2

[0044] Using the device described in Embodiment 1, the difference is that: the circuit control board described in this embodiment is provided with a remote transmission device, and the corresponding control display system is used simultaneously with the control display screen assembly and the computer.

[0045] The remote transmission device set in the circuit control board can control the operating state and parameter adjustment of the device described in this embodiment through a remote computer, and can display the data obtained by the device described in this embodiment in the measurement on the control display screen assembly Display and upload to the computer for processing, which is convenient for remote monitoring and on-site monitoring at the same time. In addition, using the computer can not only obtain data for analysis and processing, but also automatically adjust the measurement time and frequency of the entire device according to different periods of the process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com