Noodle making method of intelligent noodle maker

A noodle machine, an intelligent technology, applied in the field of food processing, can solve the problems that the mixing time and mixing speed cannot meet the dough quality, the dough quality has a great influence, and the dough is uneven, so as to shorten the dough making time, improve the user experience, and include The effect of uniform amount of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

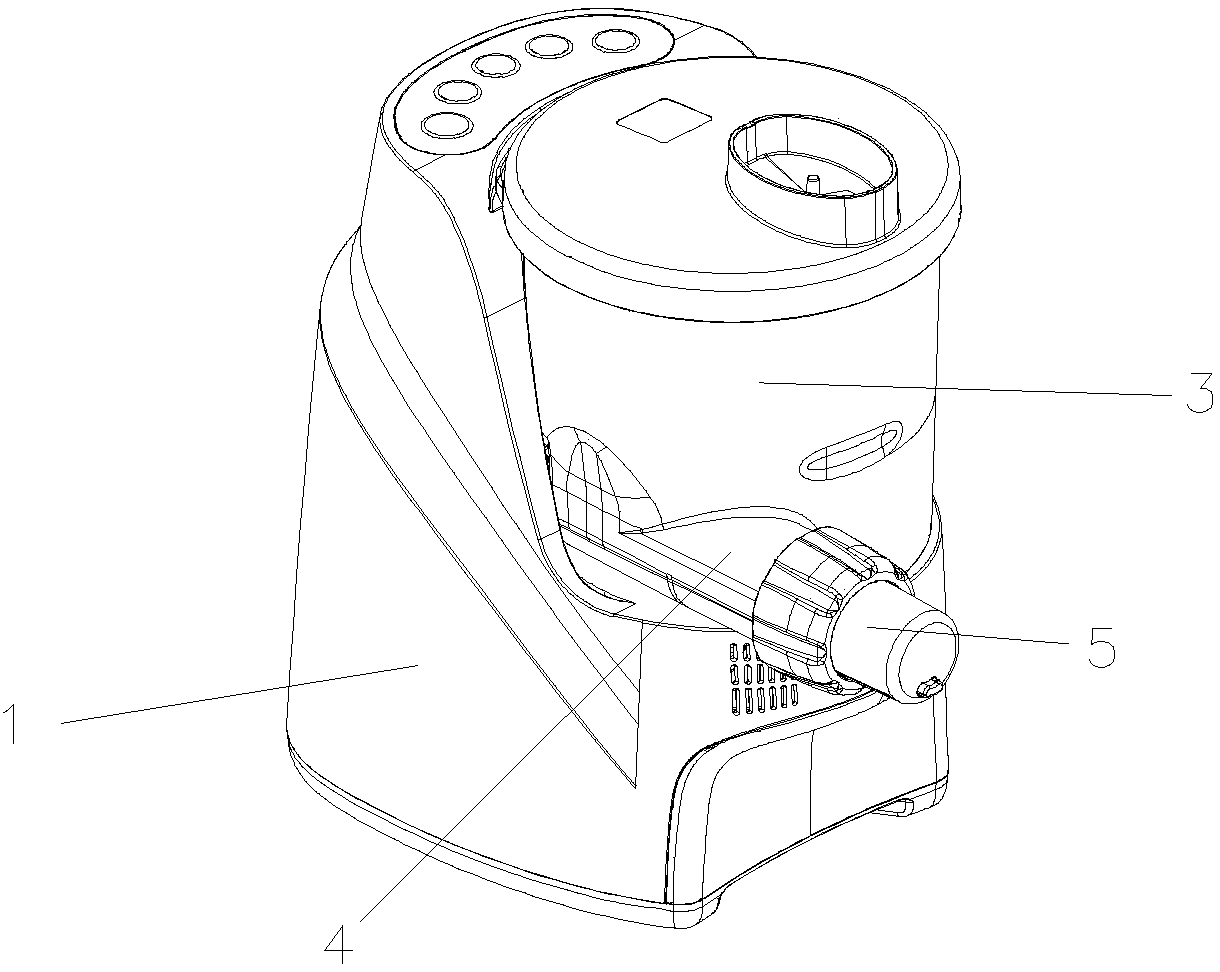

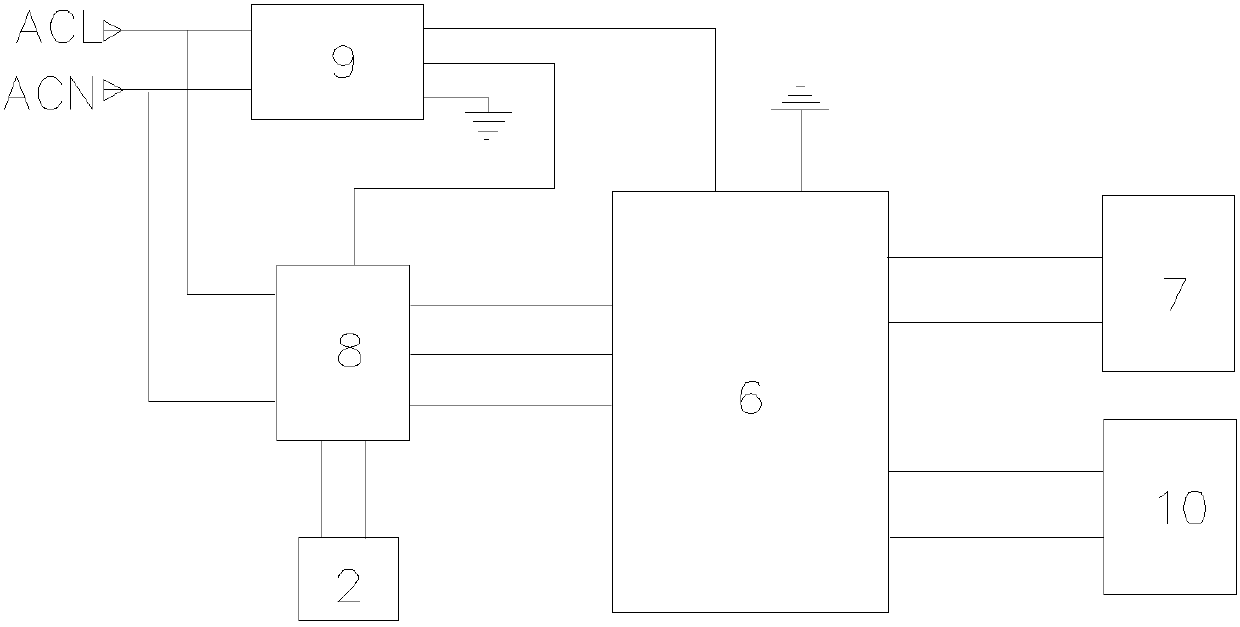

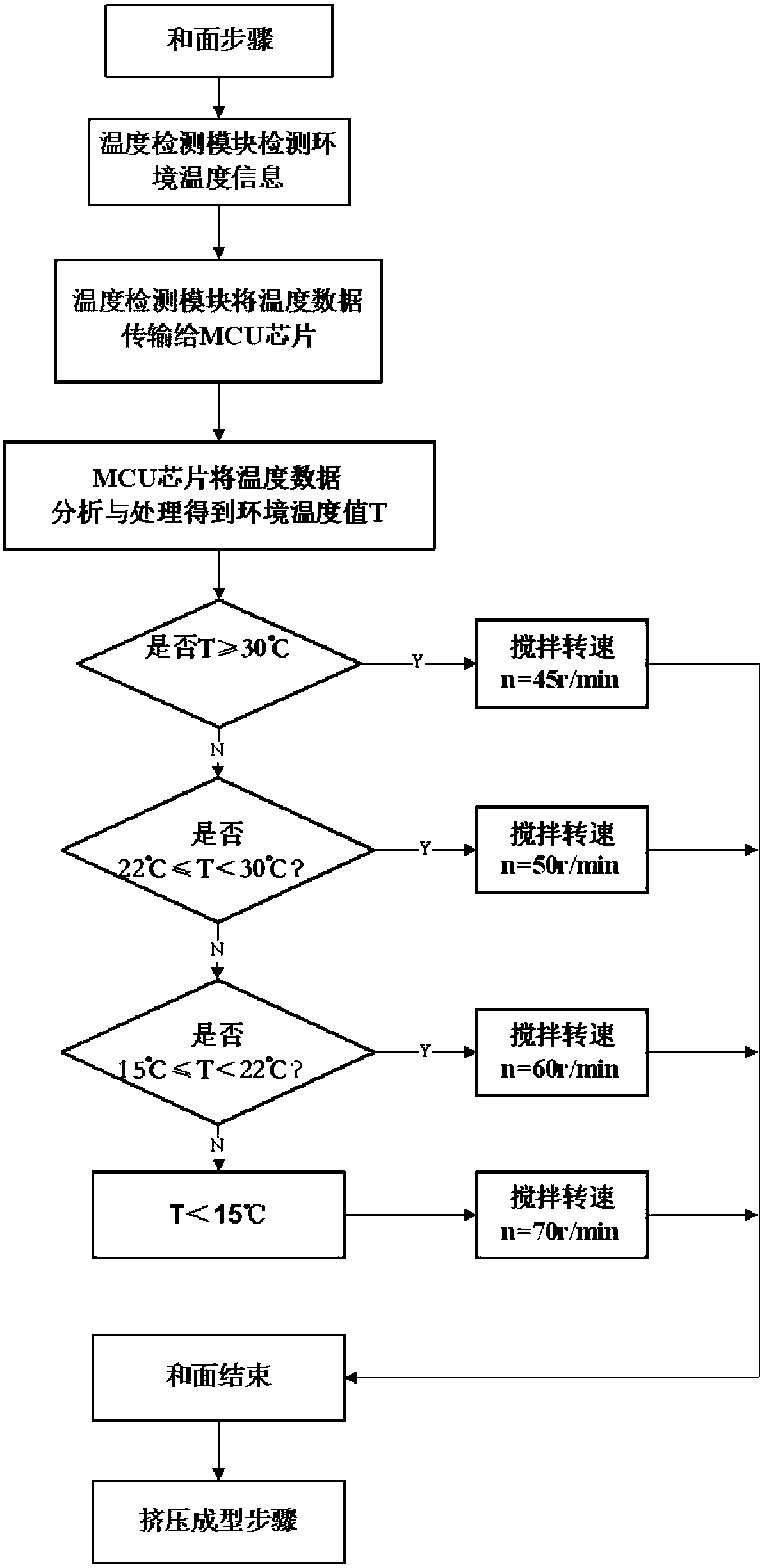

[0033] As a first embodiment of the present invention, such as figure 1 , figure 2 As shown, a noodle making method of an intelligent noodle machine, the noodle machine in the present embodiment is a vertical noodle machine, and the noodle machine includes a support 1 with a motor 2, a control unit located inside the support 1, a connection In the stirring cup 3 and the extruding cylinder 4 of the machine base 1, the stirring cup 3 is provided with a stirring rod, the extruding cylinder 4 is provided with a screw rod, and the end of the extruding cylinder 4 is provided with a die head 5, and the extruding surface The barrel 4 is placed on the lower side of the stirring cup 3, the stirring rod is vertically arranged in the stirring cup 3, the screw is arranged horizontally in the noodle extruding barrel 4, and the motor 2 drives the stirring rod and the screw to rotate , the noodle machine at least includes the following steps in the working process:

[0034] Dough mixing st...

Embodiment 2

[0042] As the second embodiment of the present invention, in the dough kneading step, the control unit controls the stirring time of the stirring rod to be different according to the difference of the external environment temperature T. The temperature of the external environment detected by the temperature detection module 7 is T, and the stirring time of the stirring rod is t. The larger T is, the smaller t is; the smaller T is, the larger t is. The stirring time t of the stirring rod is constant in each temperature range. The stirring time t of the stirring rod corresponding to different temperature ranges is different, and the higher the temperature in different temperature ranges, the smaller the corresponding t.

[0043] It is found through research that: at low temperature, that is, when T Figure 4 As shown, as the mixing time t increases, the dough quality Q gradually increases. When the mixing time t reaches t0=6min, the dough quality Q tends to be stable. In order to...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the control unit does not include a temperature detection module 7. The control unit is provided with a wireless module. APP, the control unit reads the data information in the APP through the wireless module and transmits the information to the main control module 6 for processing and analysis to obtain the current external environment temperature T, and the control unit selects the appropriate speed information according to T and the stored speed information The motor 2 is controlled to run, thereby controlling the rotating speed of the stirring rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com