Method and noodle maker for making nutritive noodles

A noodle machine and noodle technology, applied in the method and noodle machine, in the field of making nutritious noodles, can solve the problems of incomplete nutrition of noodles and the inability to produce high-nutrition noodles quickly and hygienically, and achieve high production efficiency, rich nutrition, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

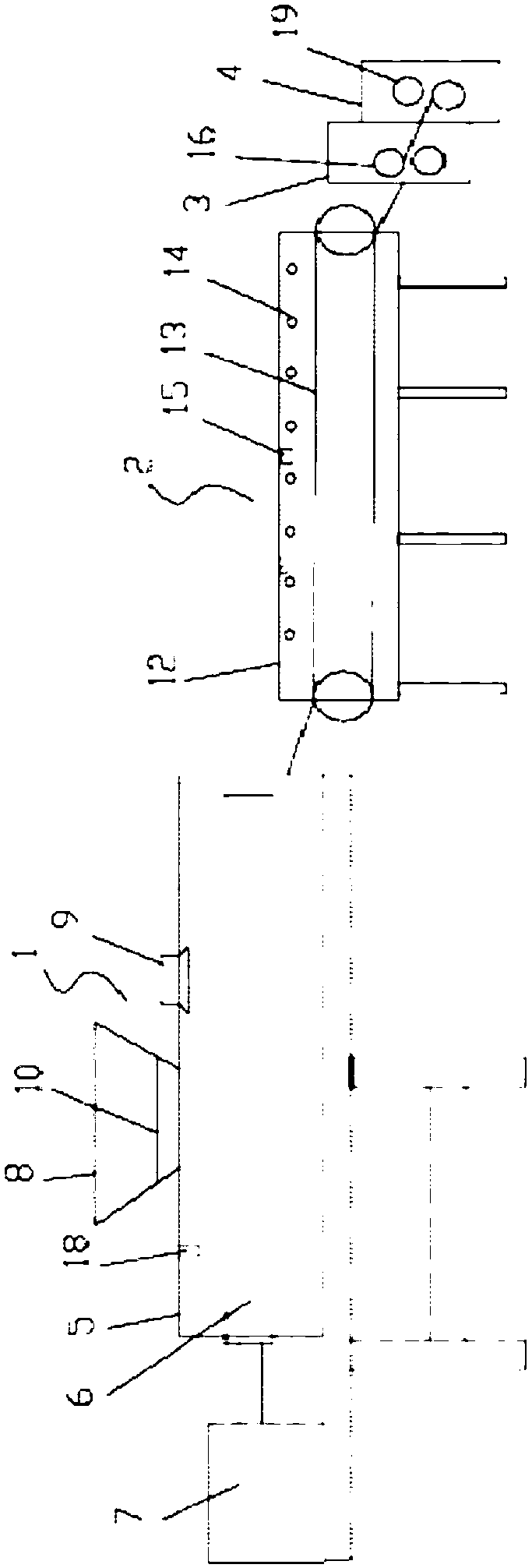

Image

Examples

Embodiment 1

[0030] Step 1: Weigh 3% corn flour, 2% oat flour, 2% mung bean flour, 3% potato flour, 3% soybean flour, 3% carrot powder, 2% yam flour, 2% chestnut flour, 55% plain flour, Edible alkali 0.1%, table salt 0.5%, water 24.4%, the mass percentage of above-mentioned material is 100%, then after above-mentioned material is mixed, send in the dough mixer and become soft dough;

[0031] Step 2: Let the soft dough reconciled in Step 1 rest for 30-40 minutes;

[0032] Step 3: Send the soft dough that has been left to stand in step 2 to the first pressing process of the noodle press machine to be pressed into a 5mm thick noodle cake, and then sequentially go through the second pressing process of the noodle press machine to be pressed into a 3mm thick noodle cake , pressed into a 1mm thick dough cake through the third pressing process;

[0033] Step 4: Cut the 1mm thick dough cake pressed into the third pressing process of step 3 into soft noodles by a cutter, and dry it outdoors to obt...

Embodiment 2

[0035] Step 1: Weigh 1% corn flour, 1% oat flour, 1% mung bean flour, 1% potato flour, 1% soybean flour, 1% carrot powder, 3% yam powder, 1% chestnut flour, 60% plain flour, Edible alkali 0.3%, table salt 1.7%, water 28%, the mass percentage of above-mentioned material is 100%, then after above-mentioned material is mixed, send in the dough mixer and become soft dough;

[0036] Step 2: Let the soft dough reconciled in Step 1 rest for 30-40 minutes;

[0037] Step 3: Send the soft dough that has been left to stand in step 2 to the first pressing process of the noodle press machine to be pressed into a 5mm thick noodle cake, and then sequentially go through the second pressing process of the noodle press machine to be pressed into a 3mm thick noodle cake , pressed into a 1mm thick dough cake through the third pressing process;

[0038] Step 4: Cut the 1mm thick dough cake pressed into the third pressing process of step 3 into soft noodles by a cutter, and dry it outdoors to obta...

Embodiment 3

[0040] Step 1: Weigh 6% corn flour, 3% oat flour, 4% mung bean flour, 3% potato flour, 5% soybean flour, 3% carrot powder, 2% yam flour, 4% chestnut flour, 45% plain flour, Edible alkali 0.15%, table salt 0.85%, water 23%, the mass percentage of above-mentioned materials is 100%, then after above-mentioned materials are mixed, send in the dough mixer and become soft dough;

[0041] Step 2: Let the soft dough reconciled in Step 1 rest for 30-40 minutes;

[0042] Step 3: Send the soft dough that has been left to stand in step 2 to the first pressing process of the noodle press machine to be pressed into a 5mm thick noodle cake, and then sequentially go through the second pressing process of the noodle press machine to be pressed into a 3mm thick noodle cake , pressed into a 1mm thick dough cake through the third pressing process;

[0043] Step 4: Cut the 1mm thick dough cake pressed into the third pressing process of step 3 into soft noodles by a cutter, and dry it outdoors to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com