Cylindrical high-temperature thermal tube-based concentrated solar distributed thermal reforming hydrogen production system

A technology of concentrating solar energy and high-temperature heat pipes, applied in the direction of hydrogen, energy input, separation methods, etc., can solve the problems of difficult carbon dioxide capture, high energy consumption, etc., and achieve the effects of reducing complexity, improving low reaction temperature, and avoiding cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

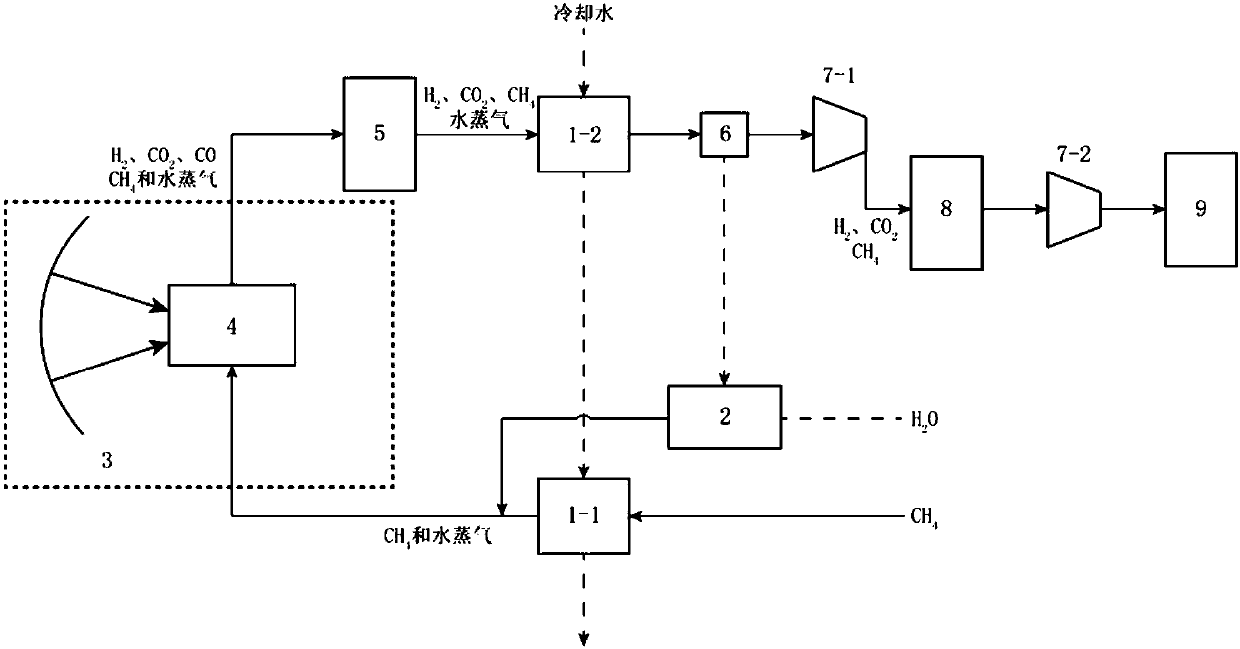

[0025] The method of producing high-purity hydrogen (purity>99.9%) using water and methane as raw materials using a cylindrical high-temperature heat pipe-based concentrating solar thermochemical hydrogen production system is as follows:

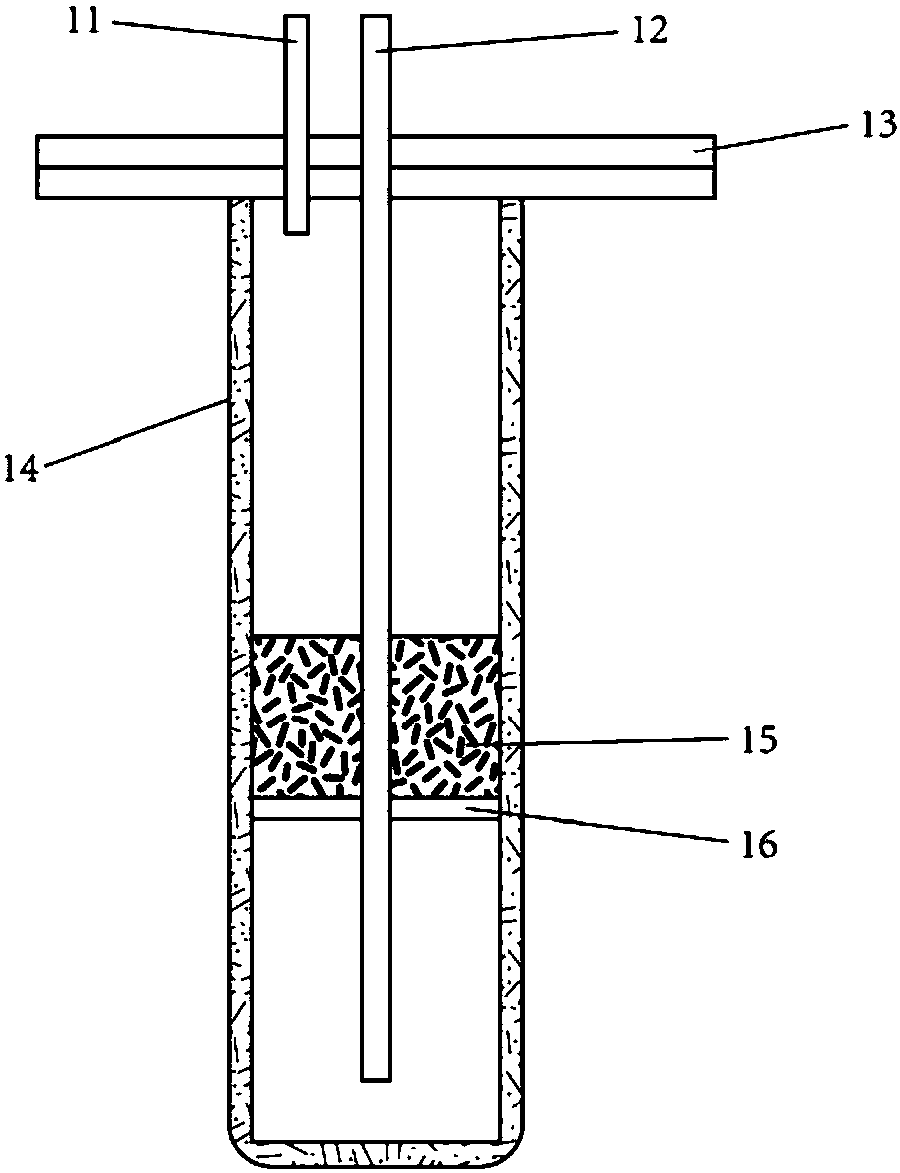

[0026] (1) Feeding and preheating: Check that all valves are closed, open the cooling water inlet valve, and then slowly rotate the pressure reducing valve and water valve at the same time to feed CH4 and H2O into the pipeline at constant pressure and constant flow, water Firstly through the steam generator 2, CH4 enters the tube side of the first heat exchanger 1-1, the water vapor flowing out of the steam generator 2 is mixed with the CH4 flowing out of the tube side of the first heat exchanger 1-1, and then passed through the feed tube Enter the reactor body, then turn on the solar biaxial electric control system, the solar concentrating device tracks the sun and starts to heat the cylindrical high-temperature heat pipe reactor;

[0027] ...

Embodiment 2

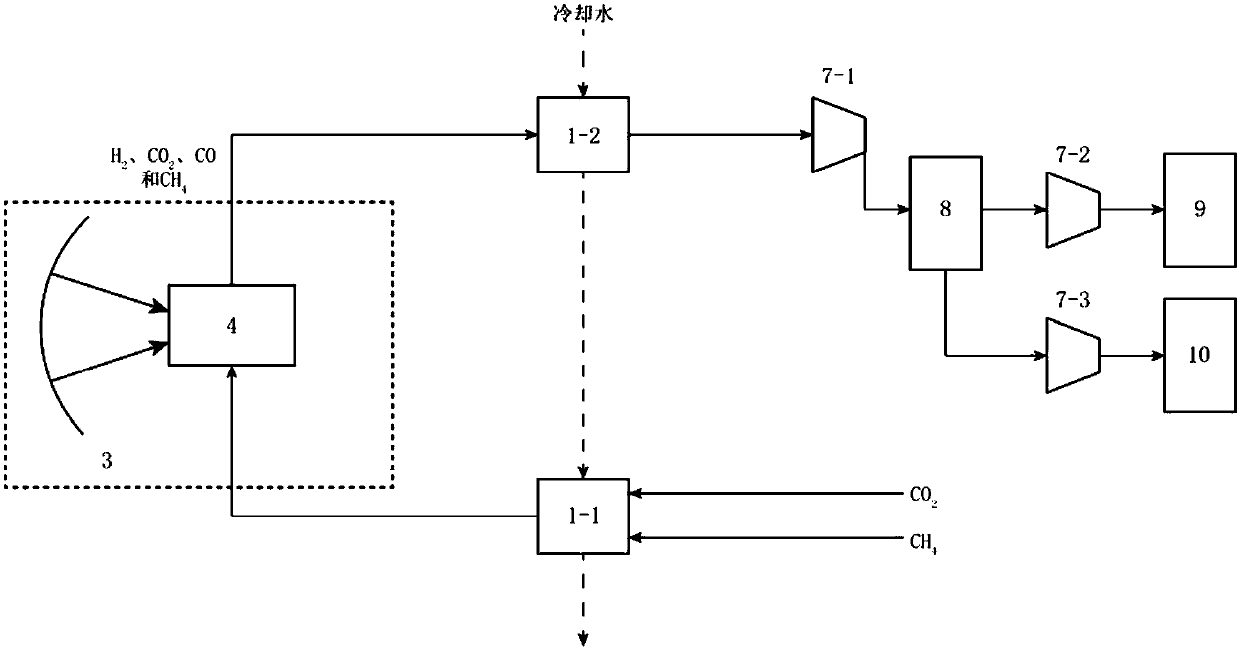

[0031]The method of producing high-purity hydrogen (purity>99.9%) using a cylindrical high-temperature heat pipe-based concentrating solar thermochemical hydrogen production system using carbon dioxide and methane as raw materials is as follows:

[0032] (1) Feeding and preheating: Check that all valves are closed, slowly rotate the pressure reducing valve to feed CO2 into the pipeline at a constant pressure, turn on the solar dual-axis electric control system, and the solar concentrating device 3 will track the sun and Start to heat the cylindrical high-temperature heat pipe reactor 4. The CO2 flowing through the reactor body is heated to 800-1000°C by the solar concentrating device. After the residual gas in the pipeline is evacuated, the inlet valve of the cooling water pipeline is opened. The high-temperature CO2 gas passes into the shell of the second heat exchanger 1-2, and heats the water flowing through the tube to about 90°C. The heated water enters the shell of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com