Flat plate type low-temperature plasma soil remediation method and device

A low-temperature plasma and soil remediation technology, which is applied in the field of ionic soil remediation methods and devices, can solve the problems of long treatment period, low adsorption efficiency, and cumbersome adsorption process, and achieve the effects of shortening the treatment period, good treatment effect and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0024] This specific embodiment discloses a flat-plate low-temperature plasma soil remediation method: the polluted soil is transported through a conveyor belt, and the polluted soil passes through a low-temperature plasma discharge area, and the low-temperature plasma discharge area is on the surface of the polluted soil particles, between the particles and the internal pores of the particles Discharge occurs, the O in the air 2 , N 2 And water molecules collide with high-energy electrons generated in the low-temperature plasma discharge area to generate high-energy groups. High-energy groups include charged particles, excited species, free radicals, electrons, and photons. High-energy groups and toxic and harmful substances in polluted soil occur The reaction produces non-toxic and harmless CO 2 and H 2 O and other small molecular substances; among them, the conveyor belt is made of conductive material and connected to the ground wire, and a high-voltage electrode layer el...

specific Embodiment 2

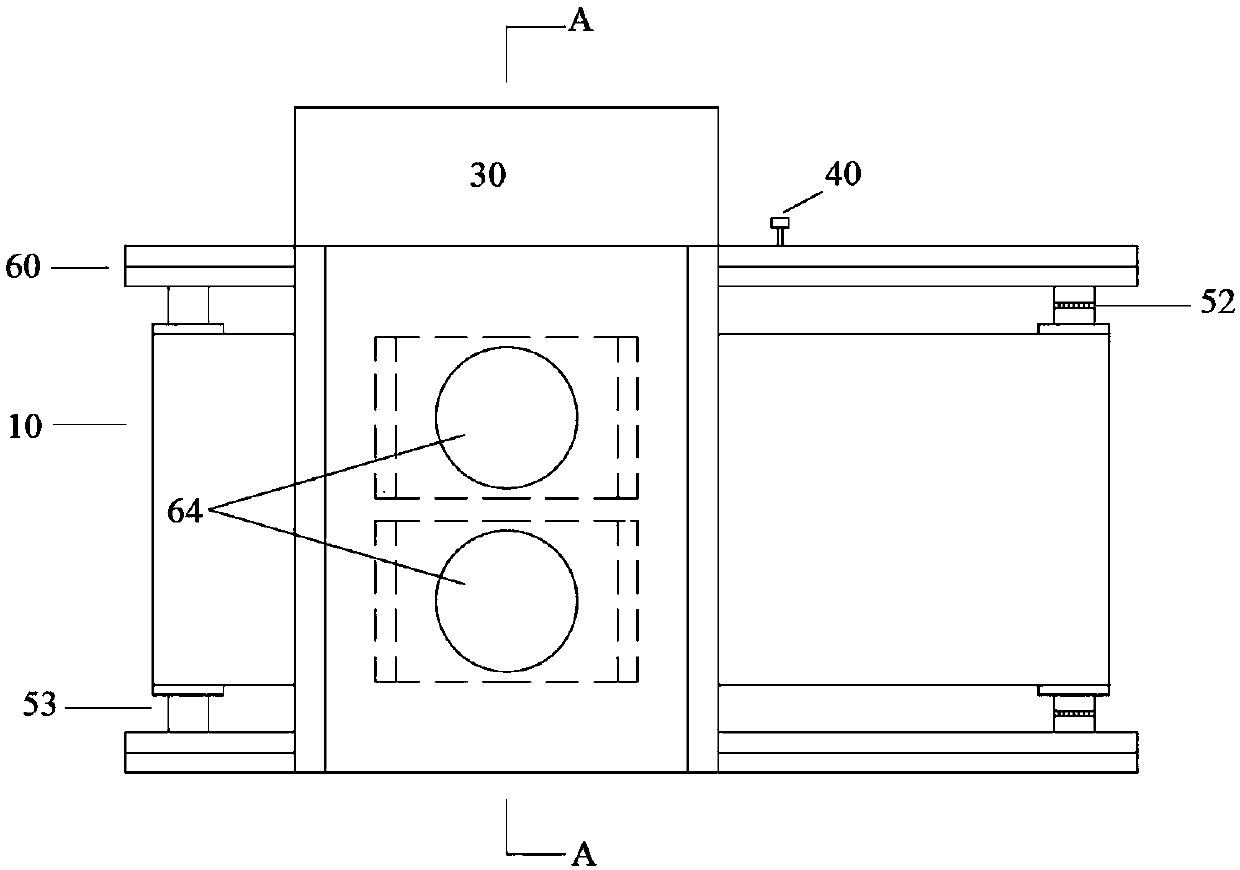

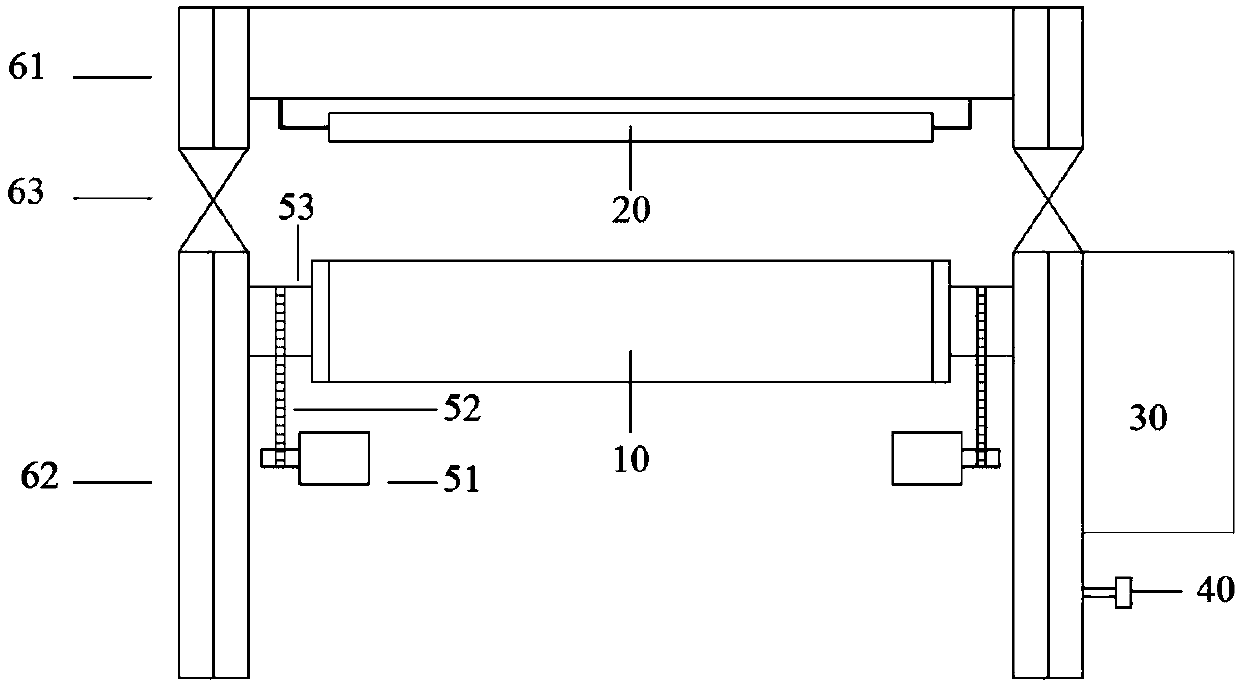

[0029] This specific embodiment discloses a flat-plate low-temperature plasma soil remediation device, including a conveyor belt 10, the conveyor belt 10 is connected to a driving device, the driving device includes a motor 51, a transmission gear 52 and a roller shaft 53, and the roller shaft 53 is a metal roller shaft. The motor 51 drives the transmission gear 52, so that the transmission gear 52 drives the roller shaft 53 to rotate, and the roller shaft 53 further drives the conveyor belt 10 to move, so that the conveyor belt 10 transports the polluted soil.

[0030] Specifically, the conveyor belt 10 is made of conductive material, and the conveyor belt 10 is connected to the ground wire through the grounding terminal 40. A high-voltage electrode layer 20 is arranged above the conveyor belt 10. The high-voltage electrode layer 20 includes a plurality of high-voltage tubes arranged side by side. The tube includes a metal rod, and a ceramic tube is sheathed outside the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com