Vertical element riveting system and riveting method thereof

A component and vertical technology, applied in the field of riveting systems, can solve problems such as low work efficiency and low qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

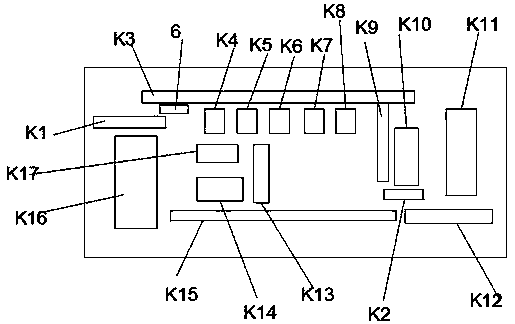

[0069] Embodiment 1. Vertical component riveting system, including: two-leg vertical component vibration feeding mechanism K1, rotating feeding mechanism 6, chain transfer mechanism K3, swing mechanism K4, positive and negative electrode adjustment mechanism K5, leg cutting mechanism K6, Shaping mechanism K7, vertical component quality inspection mechanism K8, vertical component transport mechanism K9, wire automatic clamping mechanism k12, horizontal two-leg component processing mechanism K17, horizontal two-leg component automatic clamping mechanism K13, linkage transport mechanism k15 , Finished product recovery device, positioning clip k2, first copper belt machine K10, second copper belt machine K14, left wire processing mechanism k16, right wire processing mechanism k11; among them: two-legged vertical component vibration feeding mechanism K1 A rotary feeding mechanism 6 is installed on the outer side of the end; a chain transmission mechanism K3 is installed on the outer ...

Embodiment 2

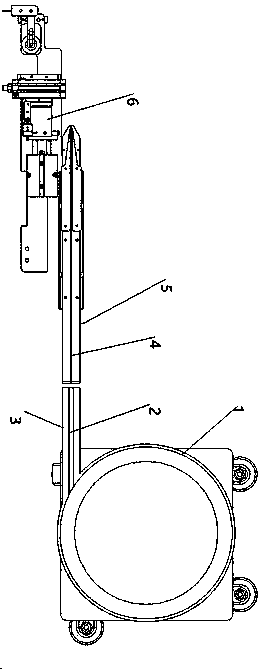

[0070] Embodiment 2. The vertical component riveting system, wherein: the two-leg vertical component vibration feeding mechanism K1 includes a vibration plate 1, a first rectangular slit 2, a vibration plate guide 3, a second rectangular slit 4, and a vibration guide 5 , Rotary feeding mechanism 6; wherein: one side of the vibration plate 1 is fixedly connected to one end of the vibration plate guide 3, and the vibration plate guide 3 is provided with a first rectangular slit 2 that penetrates the upper and lower surfaces of the vibration plate guide 3 , The other end of the vibration plate guide 3 is connected to one end of the vibration guide 5, and the vibration guide 5 is provided with a second rectangular slit 4 that penetrates the upper and lower surfaces of the vibration guide 5; A rotating feeding mechanism is placed on one side; working principle: the lower end surfaces of the vibration plate guide 3 and the vibration guide 5 are respectively installed with vibration mo...

Embodiment 3

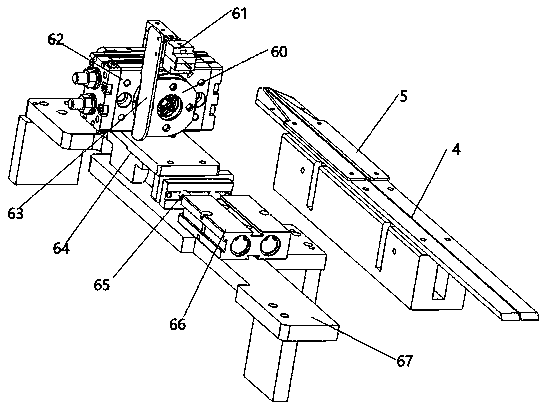

[0071] Embodiment 3, a vertical component riveting system, wherein: the rotating feeding mechanism 6 includes: a rotating disc 60, a mechanical clamp 61, a rotating cylinder 62, a connecting rod 63, a support base 64, a piston rod 65, a cylinder 66, The base 67 is composed of a support base 64 that is slidably mounted on the base 67, and a cylinder 66 is fixedly mounted on the base 67. The cylinder 66 is connected to the support base 64 through a piston rod 65; the support base 64 is fixedly mounted with a rotating Cylinder 62; the right side of the rotating cylinder 62 is connected to the rotating disc 60 through a rotating shaft; a connecting rod 63 is fixedly installed on the arc outer wall of the rotating disc 60; One end is fixedly installed with a mechanical clamp 61; working principle: the rotating cylinder 62 rotates, the mechanical clamp 61 is moved to the vibration guide 5 by the contraction of the cylinder 66, the mechanical clamp 61 clamps the diode, the cylinder 66 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com