Capacitor clamping device

A clamping device and capacitor technology, which is applied to hand-held tools, manipulators, program-controlled manipulators, etc., can solve the problems of cumbersome assembly process of capacitors and easy damage to capacitors, and achieve the effects of less manual operation, reasonable structure design and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

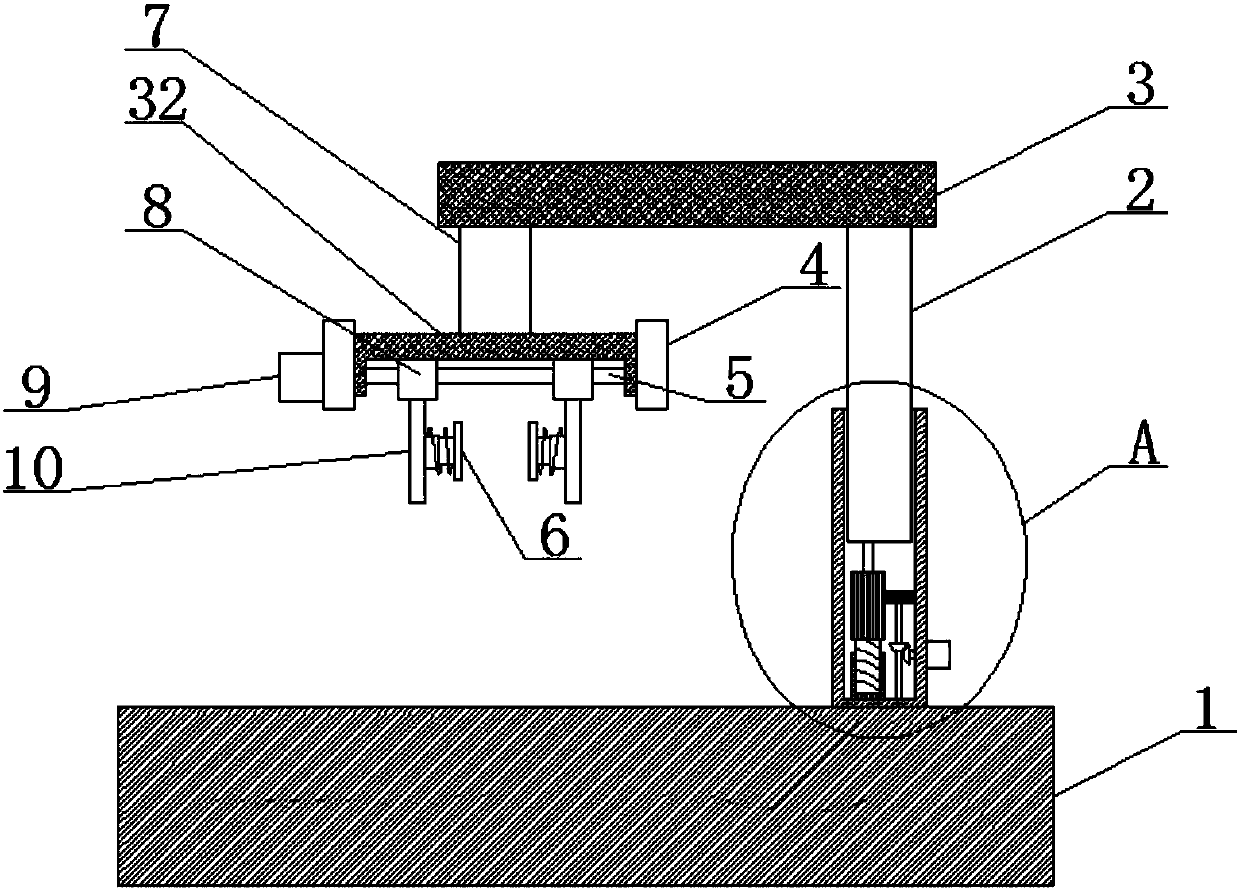

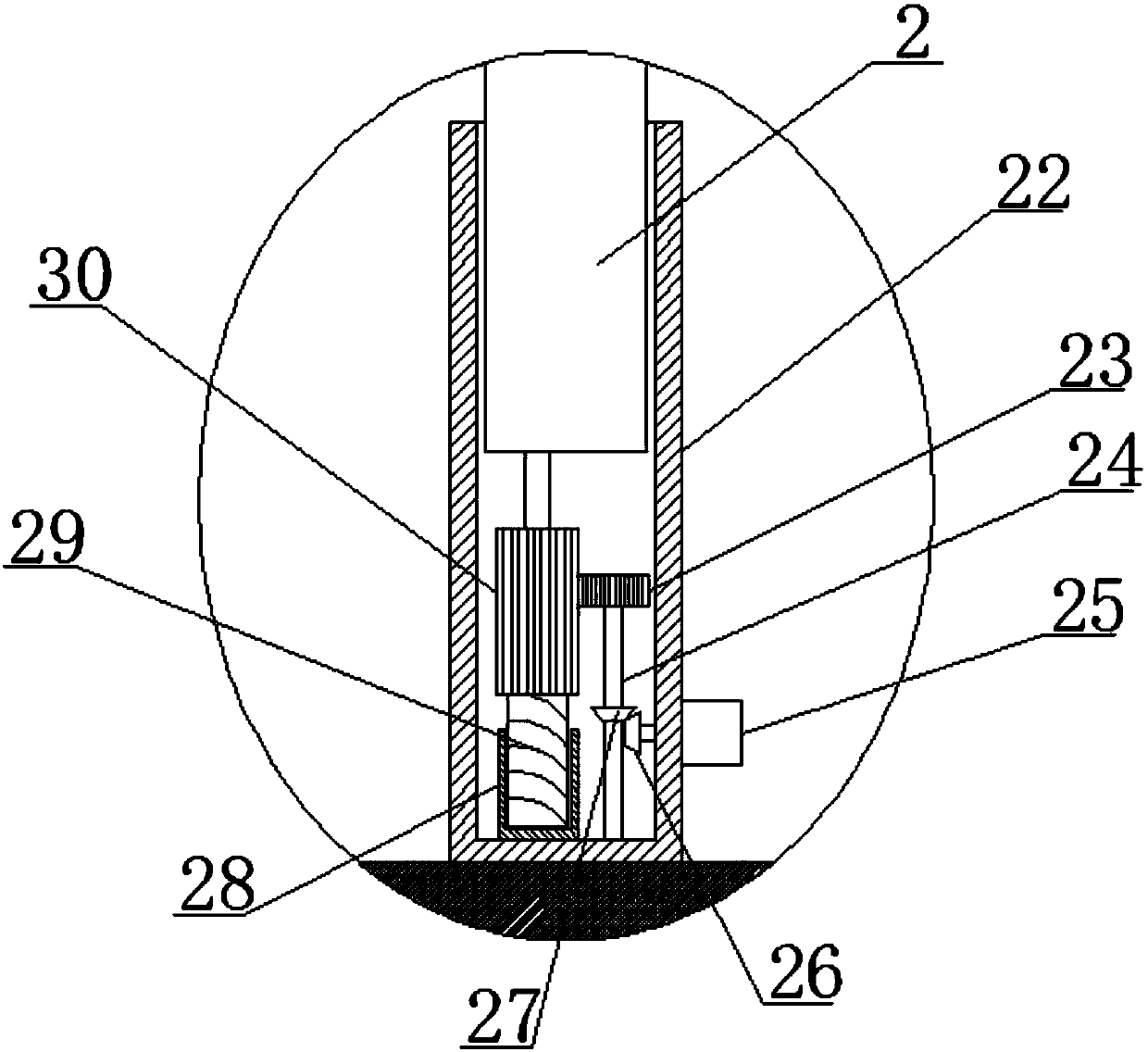

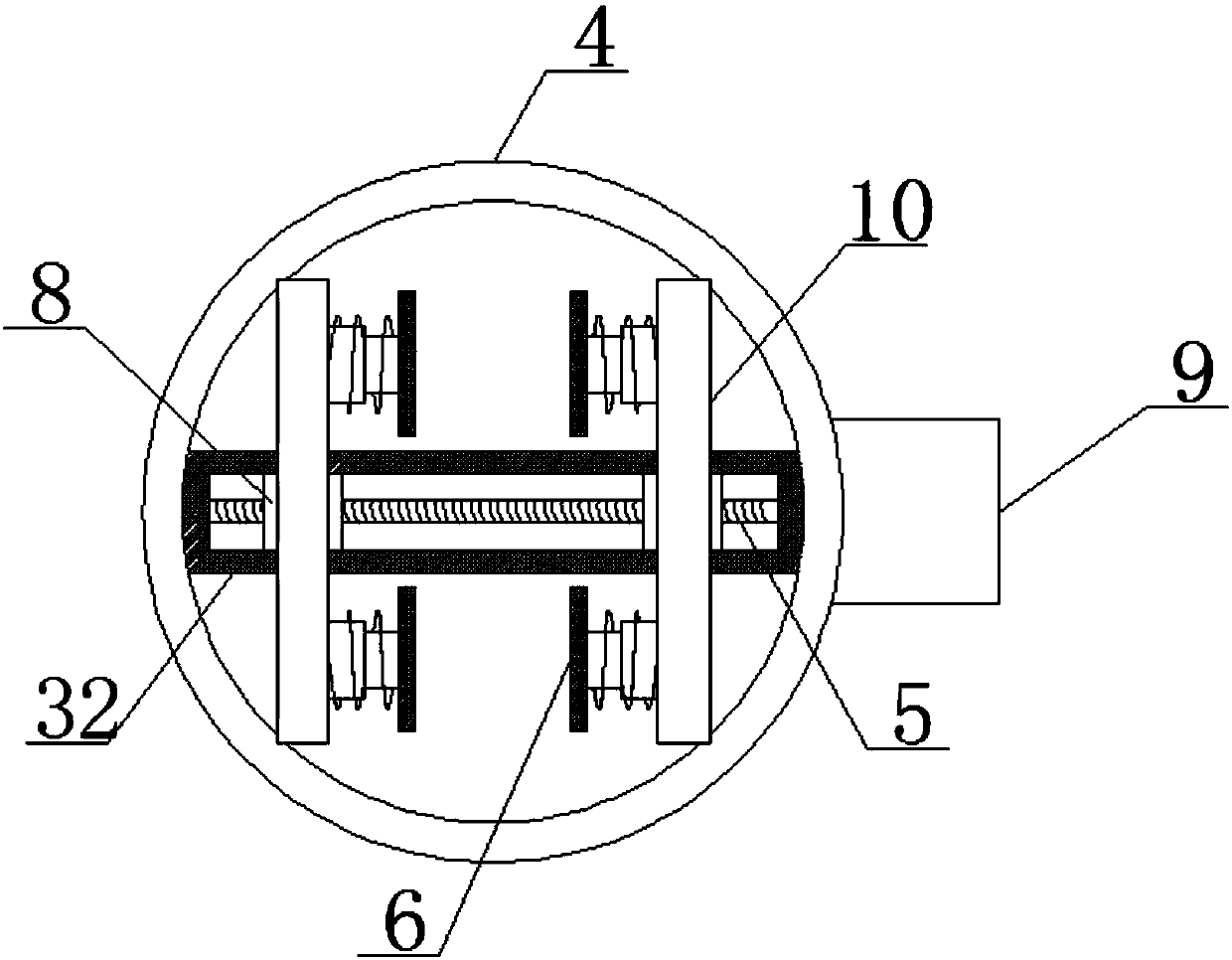

[0023] Embodiment 1: refer to Figure 1-3 , a capacitor clamping device, including a base 1, the upper end of the base 1 is provided with a lifting device, the upper end of the lifting device is fixedly connected with a support rod 3, and the lower end of the support rod 3 is provided with a mechanical arm 7, and the control mechanical arm 7 is controlled by clamping The device clamps the capacitor into the placement groove 31. The lower end of the mechanical arm 7 is provided with a clamping device. The clamping device includes a connecting rod 32 fixedly connected to the lower end of the mechanical arm 7. The outer side of the connecting rod 32 is provided with a fixed ring 4 , the middle part of the connecting rod 32 is provided with a first chute, the side wall of the fixed ring 4 is fixedly connected with the second drive motor 9, and the output shaft of the second drive motor 9 runs through the side wall of the fixed ring 4 and the connecting rod 32 in turn, the second T...

Embodiment 2

[0025] Embodiment 2: refer to Figure 2-6 , the present invention is applied to the assembling and fixing device that is used for capacitor, comprises base 1, and the middle part of base 1 is provided with device cavity, and the inner wall of device cavity is fixedly connected with first drive motor 17, and the inner wall of device cavity is rotatably connected with first Rotating shaft 18, the upper end of the first rotating shaft 18 is fixed with the second rotating disk 19, the output shaft of the first driving motor 17 is welded with the first rotating disk 14, and the upper end of the first rotating disk 14 is fixed with the fan-shaped disk 12, and the axle center of the first rotating disk and The axes of the fan-shaped disks 12 coincide, and the edge of the first rotating disk 14 is provided with a limit rod 13. The distance between the limit rod 13 and the axis of the first rotating disk 14 is slightly greater than the radius of the fan-shaped disk 12, and the edges of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com