A kind of method of supercritical ethanol modification nano-oxide

A nano-oxide and supercritical technology, which is applied in the treatment of dyed low-molecular organic compounds, bulk chemical production, and fibrous fillers. The effect of reducing agglomeration and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

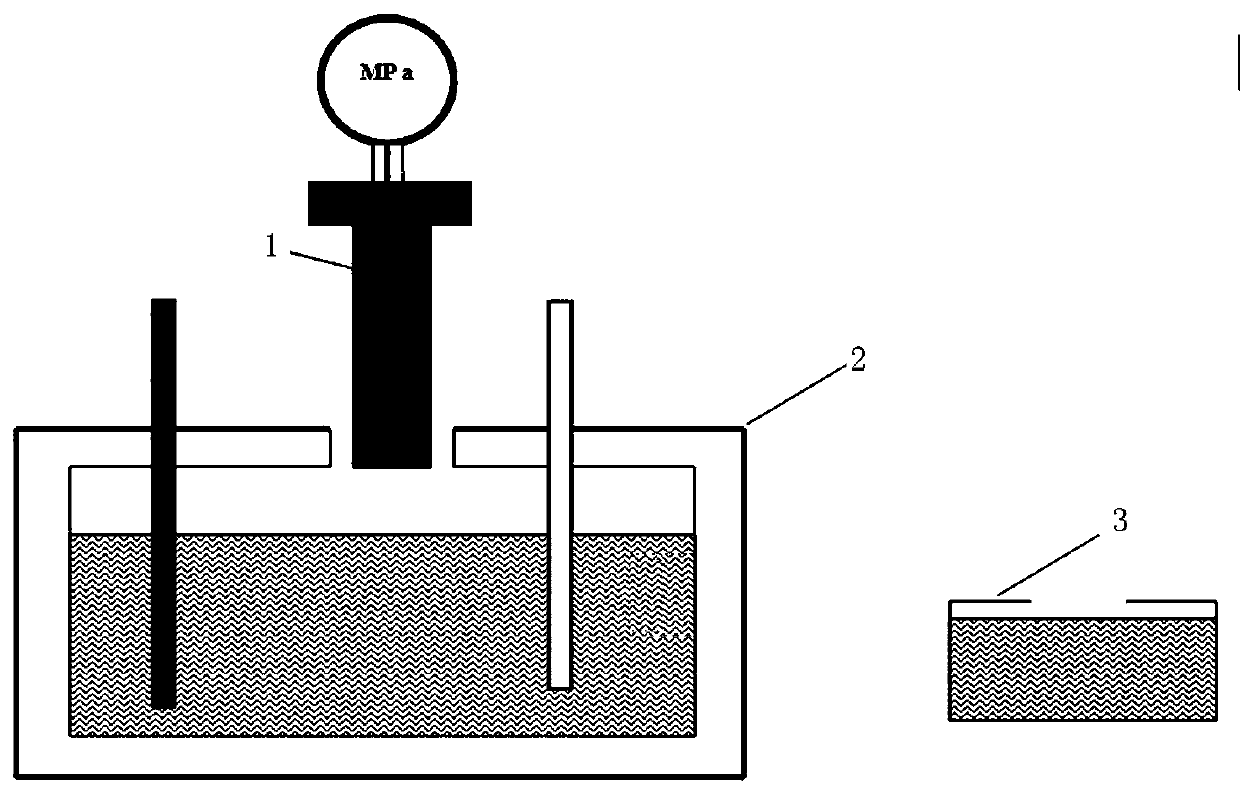

[0026] A method for modifying nano oxides with supercritical ethanol. A method for surface modification of nano-oxide by supercritical ethanol. In the first step, 100 parts of ethanol and 10 parts of nano-alumina are uniformly mixed and placed in a reactor, strictly sealed; in the second step, the temperature of the supercritical equipment reaches 240°C Place the sealed reactor in the supercritical equipment for heating; in the third step, start timing when the pressure reaches 6 MPa, and in the fourth step, after maintaining the pressure for 5 minutes, quickly put the reactor in the cooling pool to cool the cooling water as ice The temperature of the water bath is 0°C and the cooling time is 40 min. In the fifth step, the treated nanoparticles are taken out and dried in a vacuum oven. After being completely dried, the treated nanoparticles will be obtained after grinding.

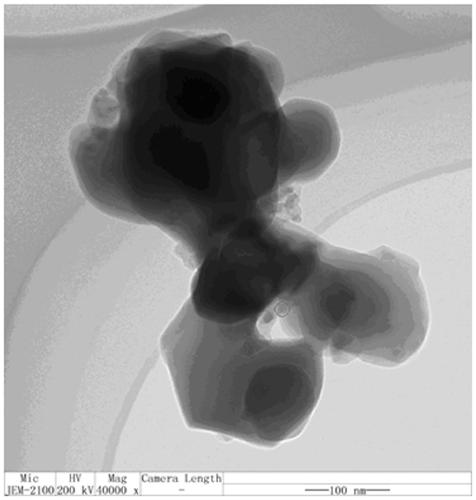

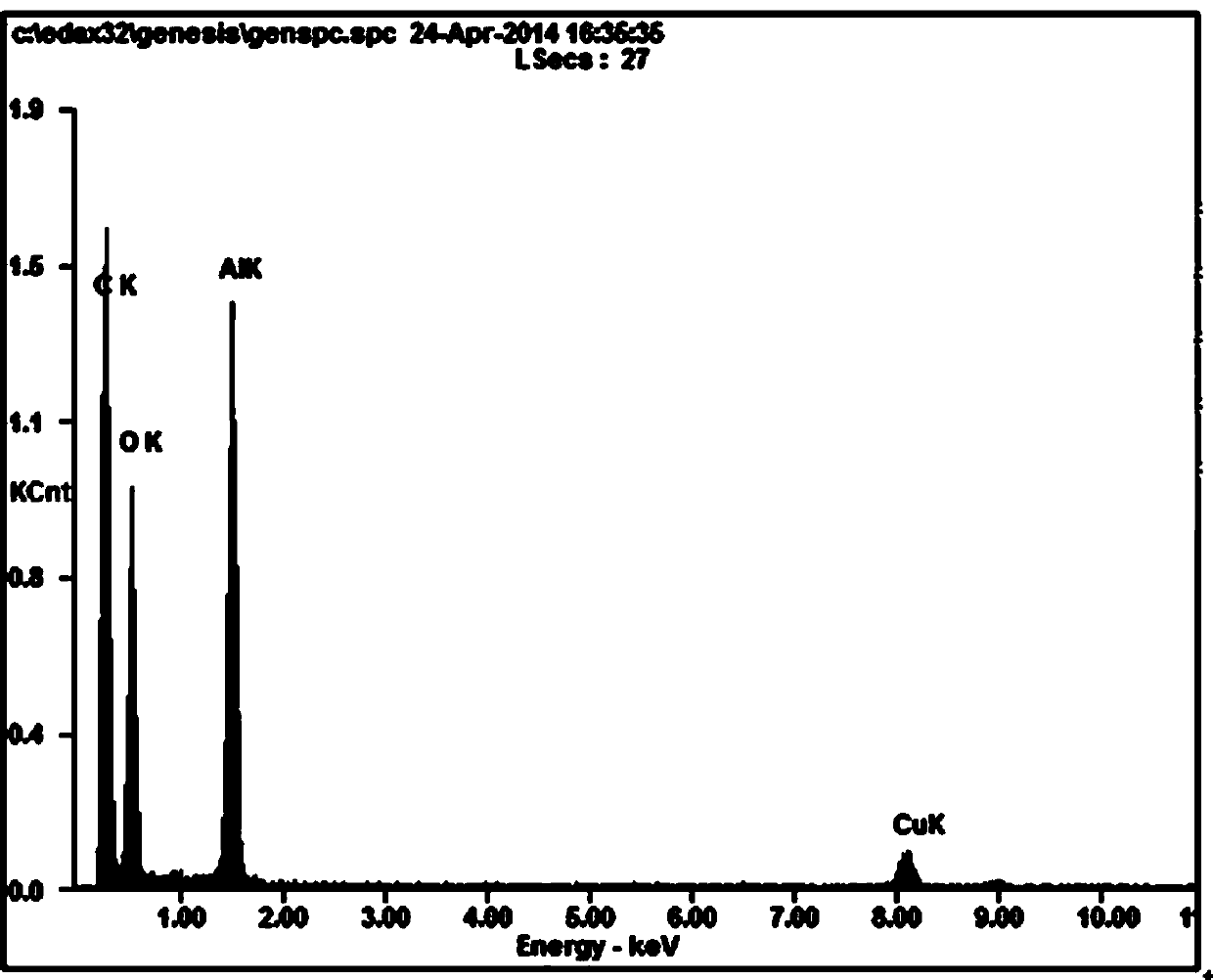

[0027] Supercritical equipment, see figure 1 ; Observe the obtained modified nano-alumina under a transmis...

Embodiment 2

[0032] A method for modifying nano oxides with supercritical ethanol. In the first step, 150 parts of ethanol and 15 parts of nano-alumina are uniformly mixed and placed in a reactor with a pressure gauge, and strictly sealed; in the second step, the sealed reactor in the previous step is placed in a heating with a temperature control device Heating in the furnace, the preset temperature is 240.5 ℃; the third step, observe the value of the pressure gauge on the reactor, when the value of the pressure gauge reaches 6.1 MPa, start timing, the time is 10 minutes; the fourth step, the reactor will be set after the specified time is reached Quickly put it into the cooling pool to cool, the cooling water is an ice-water bath, the temperature is 0℃, and the cooling time is 60 min; the fifth step, take out the treated nanoparticles and place them in a vacuum oven to dry, and then grind them in a mortar after they are completely dried After the treatment, the surface-treated nano alumin...

Embodiment 3

[0037] A method for modifying nano-silica with supercritical ethanol. In the first step, 120 parts of ethanol and 10 parts of nano-silica are uniformly mixed and placed in a reactor with a pressure gauge and strictly sealed; in the second step, the upper The sealed reaction kettle is placed in a heating furnace with a temperature control device for heating, and the preset temperature is 240 ℃; the third step, observe the pressure gauge value on the reaction kettle, and start timing when the pressure gauge value reaches 6 MPa. The fourth step is to quickly put the reaction kettle in the cooling pool to cool after the specified time is reached, the cooling water is an ice water bath, the temperature is 0℃, and the cooling time is 40 minutes; the fifth step is to take out the treated nanoparticles Place it in a vacuum oven to dry, and after it is completely dried, it is ground in a mortar to obtain surface-treated nano alumina.

[0038] The obtained modified nano silica and unmodifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com