A kind of preparation method of inorganic light-color conductive titanium dioxide powder

A technology of conductive titanium dioxide and titanium dioxide, which is applied in chemical instruments and methods, inorganic pigment treatment, dyeing low-molecular organic compound treatment, etc., can solve the problems of product agglomeration, equipment corrosion, difficult removal, etc., to reduce production costs and reduce the amount of addition , easy to combine effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Take 25g of ATO gel (solid content is 28.6%), add 135g of distilled water to dilute, cut with a shear emulsifier for 15min to make it evenly dispersed, add ammonia water (mass fraction of 25%-28%) dropwise under stirring dissolved, the pH was adjusted to 10, and the peptization was allowed to stand, the solution was a transparent colloid, and the ATO hydrosol was obtained.

[0053] 2. Add 49.7 g of titanium dioxide slurry (with a solid content of 50%) without any modification on the surface to the ATO hydrosol to obtain a mixed solution a.

[0054] 3. Emulsify and shear the mixed solution a for 10 minutes, add 1:10 diluted acetic acid dropwise under stirring with a magnetic stirrer until the pH of the mixed solution a is 4, and form a mixed solution b.

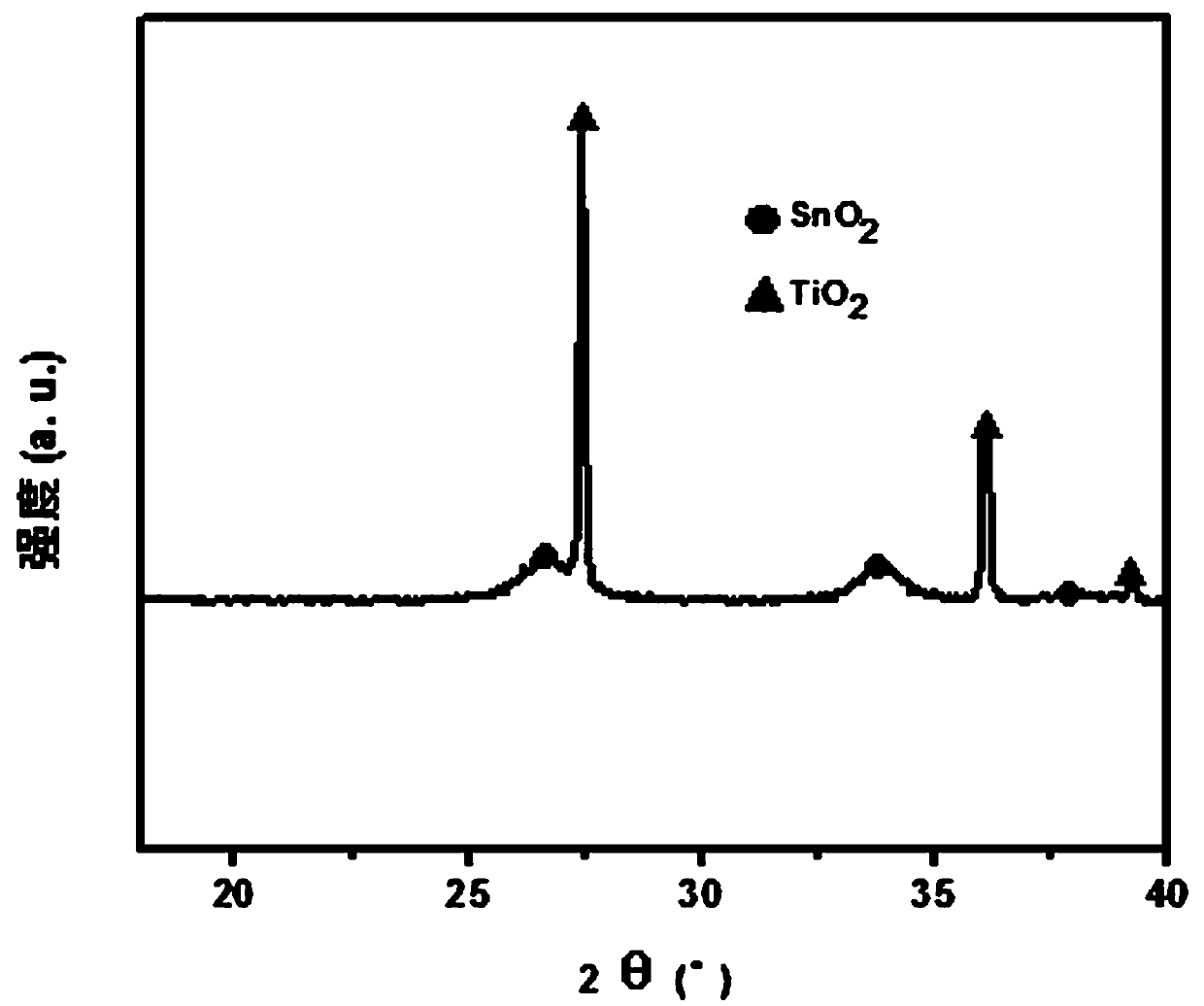

[0055] 4. Evaporate the mixed solution b to dryness in a water bath at 90°C, pulverize it into fine particles, calcinate at 500°C for 3 hours, grind it, and measure the volume resistivity of the powder to be 25Ω·cm. ...

Embodiment 2

[0058] 1. Take 20g of ATO gel (solid content is 28.6%), add 108.7g of distilled water to dilute, cut with a shear emulsifier for 15min, add tetraethylenepentamine peptizer dropwise under stirring to adjust the pH to 11.5, and let it stand for peptization. A transparent and clear ATO hydrosol was obtained.

[0059] 2. Add 38.4 g of titanium dioxide slurry (with a solid content of 50%) whose surface is coated with alumina and silicon oxide into the ATO hydrosol to obtain a mixed solution a.

[0060] 3. The mixed solution a was emulsified and sheared for 10 minutes, and dilute nitric acid was added dropwise under magnetic stirring until the pH of the mixed solution was 2.5 to form a mixed solution b.

[0061] 4. Mature the mixed solution b in a 60°C water bath first, then transfer it to a 90°C water bath to evaporate to dryness, pulverize into fine particles, calcinate at 600°C for 1 hour, grind, and measure the volume resistivity of the powder to be 35Ω·cm.

[0062] Such as i...

Embodiment 3

[0064] 1. Take 2.37kg of gel ATO (solid content is 20%), add 8.9kg of distilled water, cut it with a shear emulsifier for 15min, add dropwise ammonia water peptization solution with pH 11 under stirring, let it stand for peptization, after 24h Add 50 mL of ethylenediamine dropwise until the solution is transparent to obtain ATO hydrosol.

[0065] 2. Add 1.6 kg of titanium dioxide slurry (with a solid content of 50%) whose surface is coated with silicon oxide into the ATO hydrosol to obtain a mixed solution a.

[0066] 3. Cut the mixed solution a with a shear emulsifier for 10 minutes, add acetic acid dropwise under mechanical stirring until the pH of the mixed solution is 2, and form a mixed solution b.

[0067] 4. Rotate the mixed solution b in a water bath at 60°C. After about 30 minutes, raise the temperature of the water bath to 90°C, concentrate until the solution can be poured out, transfer it to a vacuum drying oven at 150°C for drying, and crush it into fine particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com