A papermaking retention aid and its preparation method and application

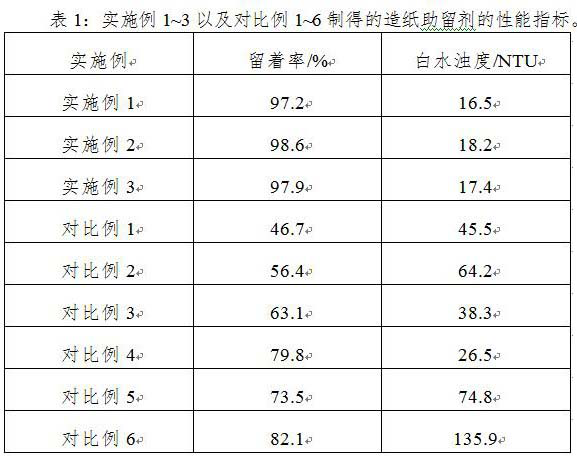

A technology of retention aid and auxiliary agent, applied in the direction of addition of retention aid, papermaking, textiles and papermaking, etc., can solve the problem of low retention rate of short fibers, achieve good retention effect, reduce white water turbidity, and improve retention. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a method of preparing a papermaking agent, the method comprising the steps of:

[0026] (1) Mix the acrylamide, cationic monomer, structural modulator, hydrophobic monomer, N-vinylformamide, and cationic surfactant by water, to obtain a mixed liquid;

[0027] (2) The mixed liquid is oxygen, and then the polymerization aid is added to initiate the polymerization, obtain a gum, and then sequentially pass the glyph, dry and pulverize, to obtain a copolymer; In some specific embodiments, the step of breaking the bulk gel into a small piece of gel, and then a small piece of glue before granulating, drying, and pulping The conventional granulation is sequentially passed through granulation, dried and pulverized to obtain the copolymer;

[0028] (3) The copper powder is prepared by water into a copolyte aqueous solution, and then the liquid broform and aqueous sodium hydroxide aqueous solution are sequentially added to the copolypourne solution to ob...

Embodiment 1

[0046] The raw materials involved in the copolymerization process used in the present embodiment are as follows:

[0047] Acrylamide 120g, acryloyloxyethyltrimethylammonium chloride (cationic monomer) 60g, N, N-methylene bis acrylamide (structural modulator) 0.01 g, cephalkyl dimethylanyl Ammonium chloride (hydrophobic monomer) 3g, N-vinylformamide 20g, octadecyltrimethylammonium chloride (cationic surfactant) 5g, water 792 g, polymerization auxiliaries 0.13g, wherein polymerization aid It contains 0.02 g of sodium ethylenediamine, 0.02 g of sodium formate, 0.03 g of azo diisobutyrid, 0.03 g of ammonium sulfate, and ferrous sulfate 0.03 g.

[0048] The preparation method includes the following steps:

[0049] (A) copolymerization: Acrylamide, acryoyloxyethyltrimethyl chloride, N, N-methylene bis acrylamide, cetyl ammonium chloride, and acrylate, n, N-methylene bis acrylamide, cetyl ammonium chloride N-vinylformamide, octadecyl trimethylcylammonium chloride and water mixed with wat...

Embodiment 2

[0052] The raw materials involved in the copolymerization process used in the present embodiment are as follows:

[0053] Acrylamide 150g, methacryloxyethyltrimethyl ammonium chloride (cationic monomer) 90g, seasonal glutaiol triolene ether (structured modifier) 0.05 g, octadecyl dimethylanyl chloride Ammonium (hydrophobic monomer) 6 g, N-vinylformamide 30g, dodecyl dimethylbenzyl chloride (cationic surfactant) 8g, water 716g, polymerization auxiliaries 0.19g, wherein polymerization aid It contains 0.03 g of sodium ethylenediamine, 0.01 g of sodium formate, 0.1 g of azo di isodaryrile, 0.03 g ammonium sulfate, 0.02 g of sodium bisulfite.

[0054] The preparation method includes the following steps:

[0055] (A) copolymerization: Acrylamide, methacryloxyethyltrimethyl ammonium chloride, pentyl methacrylate ether, octadecyl dimethyl ammonium chloride, N- Vinylformamide, dodecyl dimethylbenzyl chloride is mixed with water, adjust the system pH to 4.0 with an amino sulfonic acid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com