Papermaking retention aid, preparation method and application thereof

A technology of retention aids and additives, which is applied in the direction of addition of retention aids, papermaking, textiles, and papermaking. It can solve the problems of low retention rate of short and small fibers, achieve good retention effect, reduce white water turbidity, and improve retention. The effect of the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

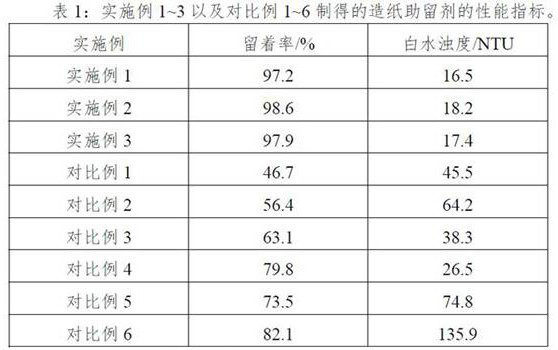

Examples

preparation example Construction

[0025] The present invention provides a kind of preparation method of papermaking retention aid in the first aspect, described method comprises the steps:

[0026] (1) Mix acrylamide, cationic monomer, structure regulator, hydrophobic monomer, N-vinyl formamide and cationic surfactant with water to obtain a mixed solution;

[0027] (2) Nitrogen is passed through the mixed liquid to remove oxygen, and then a polymerization assistant is added to initiate a polymerization reaction to obtain a jelly, and then the jelly is sequentially granulated, dried and crushed to obtain a copolymerized powder; In some specific embodiments, before the jelly is granulated, dried and pulverized, it also includes the step of breaking the large jelly into small pieces of jelly, and then the small piece of jelly The solids are sequentially granulated, dried and pulverized to obtain the copolymerized powder;

[0028] (3) Prepare the copolymerized powder with water into an aqueous copolymerized powde...

Embodiment 1

[0046] The raw materials involved in the copolymerization process used to prepare paper retention aids in this embodiment are as follows:

[0047] 120g of acrylamide, 60g of acryloyloxyethyltrimethylammonium chloride (cationic monomer), 0.01g of N,N-methylenebisacrylamide (structure regulator), hexadecyldimethylallyl Ammonium chloride (hydrophobic monomer) 3g, N-vinylformamide 20g, octadecyltrimethylammonium chloride (cationic surfactant) 5g, water 792g, polymerization aid 0.13g, of which, polymerization aid Contains 0.02g of disodium edetate, 0.02g of sodium formate, 0.03g of azobisisobutylamidine dihydrochloride, 0.03g of ammonium persulfate, and 0.03g of ferrous sulfate.

[0048] The preparation method comprises the following steps:

[0049] (a) Copolymerization: Add acrylamide, acryloyloxyethyltrimethylammonium chloride, N,N-methylene bisacrylamide, hexadecyldimethylallyl ammonium chloride, After mixing N-vinylformamide, octadecyltrimethylammonium chloride and water even...

Embodiment 2

[0052] The raw materials involved in the copolymerization process used to prepare paper retention aids in this embodiment are as follows:

[0053] Acrylamide 150g, methacryloxyethyltrimethylammonium chloride (cationic monomer) 90g, pentaerythritol triallyl ether (structure regulator) 0.05g, octadecyldimethylallyl chloride Ammonium (hydrophobic monomer) 6g, N-vinylformamide 30g, dodecyldimethylbenzyl ammonium chloride (cationic surfactant) 8g, water 716g, polymerization aid 0.19g, of which, polymerization aid Contains 0.03 g of disodium edetate, 0.01 g of sodium formate, 0.1 g of azobisisoheptanonitrile, 0.03 g of ammonium persulfate, and 0.02 g of sodium bisulfite.

[0054] The preparation method comprises the following steps:

[0055] (a) Copolymerization: Add acrylamide, methacryloyloxyethyltrimethylammonium chloride, pentaerythritol triallyl ether, octadecyldimethylallyl ammonium chloride, N- After mixing vinylformamide, dodecyldimethylbenzyl ammonium chloride and water e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com