Granulation polishing film, preparing method thereof and application thereof

A polishing film and granulation technology, which is applied in the field of grinding and polishing, can solve the problems of poor wear resistance and short service life, and achieve the effects of good grinding quality, high grinding efficiency and good self-sharpening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

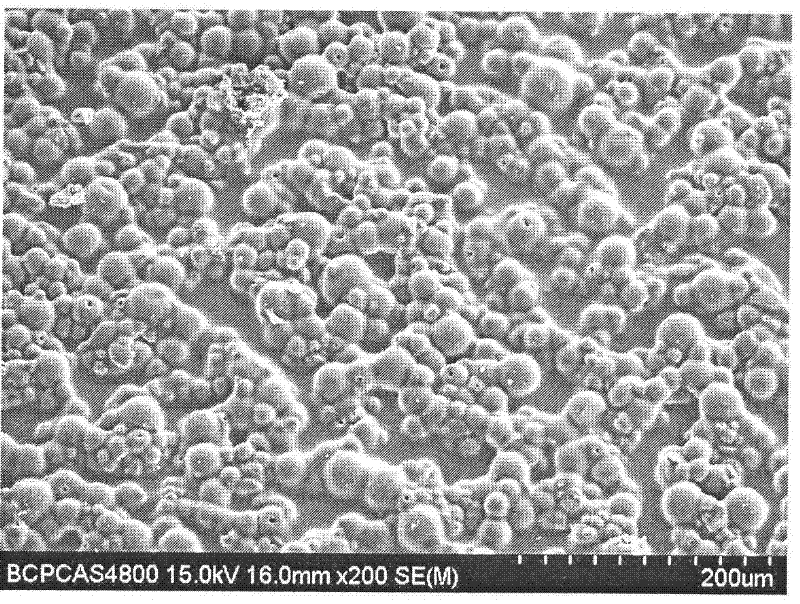

[0025] The preparation method of granulated polishing film comprises the following steps:

[0026] Step 1, prepare granulation slurry: disperse the abrasive powder in one or more metal oxide sols or silica sols, add inorganic binders or organic binders, add auxiliary agents, and use ball milling or sand Dispersion methods such as grinding are uniformly dispersed;

[0027] The abrasive powder in the granulation slurry includes: diamond, silicon carbide, alumina, zirconia, modified cerium-aluminum oxide, cubic boron nitride or silica and other superhard abrasives with an average particle size of ≤3 μm; The average particle size of the abrasive powder for fine grinding is ≤ 1 μm, and the average particle size of the abrasive powder for medium grinding is ≤ 3 μm.

[0028] The metal oxide sol in the granulation slurry is one or more of alumina sol, magnesia sol, titania sol or zirconia sol with a concentration of 10% to 60%, or a concentration of 10% to 60%. The remaining silica ...

Embodiment 1

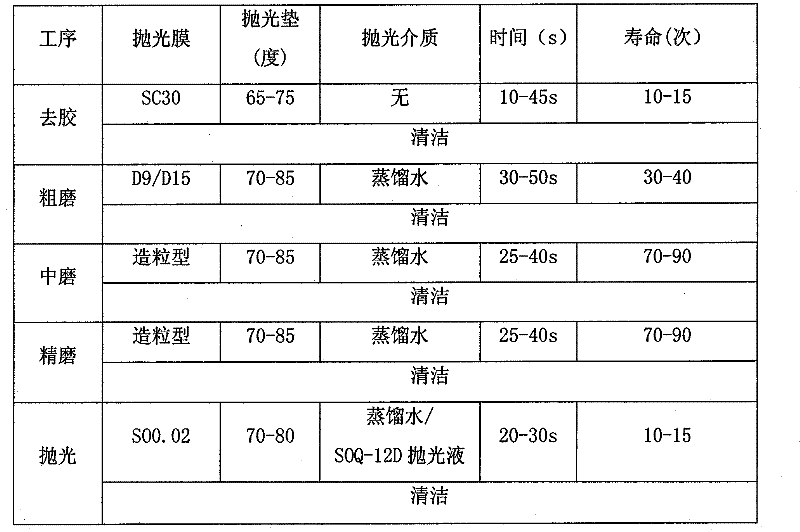

[0037] Take 1Kg of diamond micropowder with an average particle size of 1μm, add 11Kg of silica sol (homemade or commercially available) with a concentration of 40%, 100g of dispersant, and a little defoamer, and use a ball mill to disperse the above mixed solution; The granulation test of the dispersed slurry was carried out on a spray dryer. The inlet temperature was 240 °C, the outlet temperature was 110 °C, and the atomizer speed was 35000 r.p.m to obtain spherical composite abrasive particles with an average particle size of 18 μm; Abrasive particles 1.5Kg, add polyester glue, epoxy resin glue, epoxy resin toughening agent and a mixture of acetone, toluene, methyl ethyl ketone, ethyl acetate, and disperse the above mixture by a high-speed mixer for 120min. The coating machine was applied to the 75 μm polyester film treated with 5 μm primer, and the thickness of the abrasive layer was 40 μm. After drying, a granulated polishing film for fine grinding of optical fiber connec...

Embodiment 2

[0039] Take 1.5Kg of diamond micropowder with an average particle size of 2μm, add 5Kg of silica sol (homemade or commercially available) with a concentration of 20%, a little defoamer and dispersant, and use a ball mill to disperse the above mixed solution; The granulation test of the dispersed slurry was carried out on a spray dryer. The inlet temperature was 230 °C, the outlet temperature was 110 °C, and the atomizer rotation speed was 33000 r.p.m to obtain spherical composite abrasive particles with an average particle size of 20 μm; Abrasive particle 2Kg, add polyester glue, epoxy resin glue, epoxy resin toughening agent, curing agent and mixture of toluene, methyl ethyl ketone, xylene, acetone, add a little leveling agent, and mix the above mixture with a high-speed mixer Disperse for 120min, and use a roll coater to coat on 75μm polyester film treated with 4μm primer, and the thickness of the abrasive layer is 45μm. After drying, a granulated polishing film for grinding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com