High-impact wear-resistant glass fiber reinforced POK-HDPE composite material and preparation method thereof

A composite material and high-impact technology, which is applied in the field of high-impact and wear-resistant glass fiber reinforced POK-HDPE composite materials and its preparation, can solve the problems of lower resistivity, lower strength, and higher requirements for dimensional accuracy, and achieve no Easy to rub off, high impact strength, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

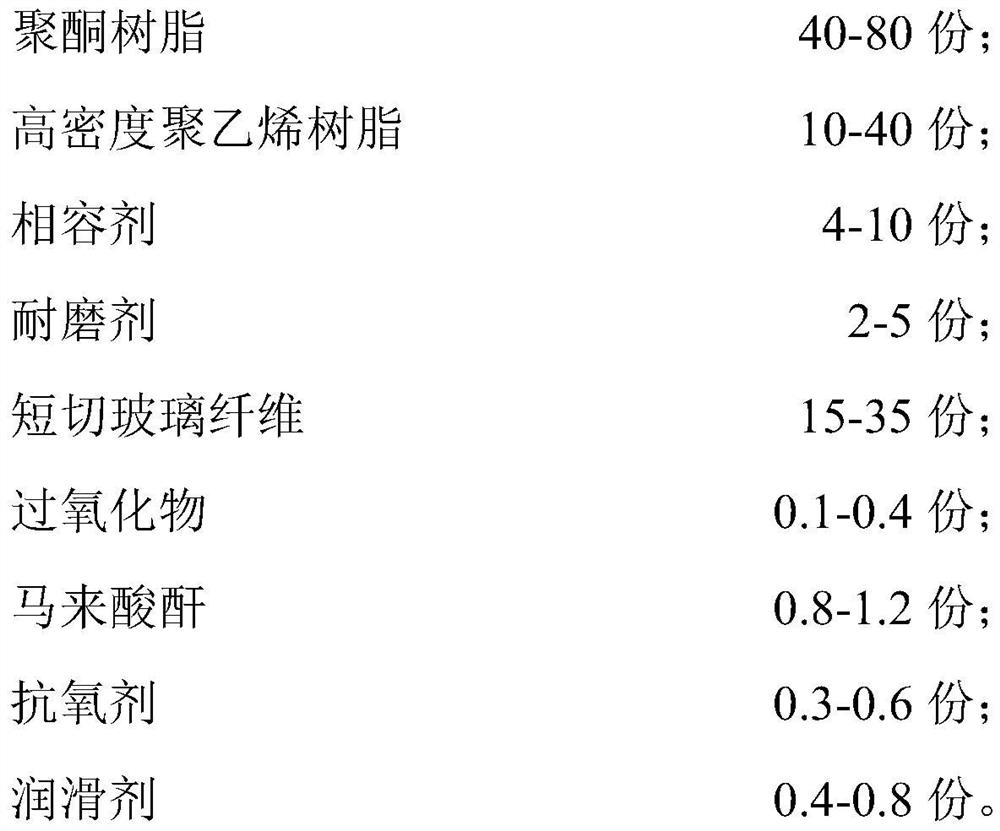

[0044] A high-impact and wear-resistant glass fiber reinforced POK-HDPE composite material, comprising:

[0045]

[0046] Put the above materials into the mixer and mix them evenly, then put the mixed materials into the main lower barrel of the extruder and granulate through the extruder. During the extrusion process, 27 parts of chopped glass fibers are fed through the side The temperature of each temperature zone of the extruder is 240°C in zone 1, 240°C in zone 2, 240°C in zone 3, 240°C in zone 4, 220°C in zone 5, 200°C in zone 6, and 200°C in zone 7. 200°C, 200°C in zone 8, 200°C in zone 9, 230°C at the head, and the screw speed of the extruder is 300rpm.

Embodiment 2

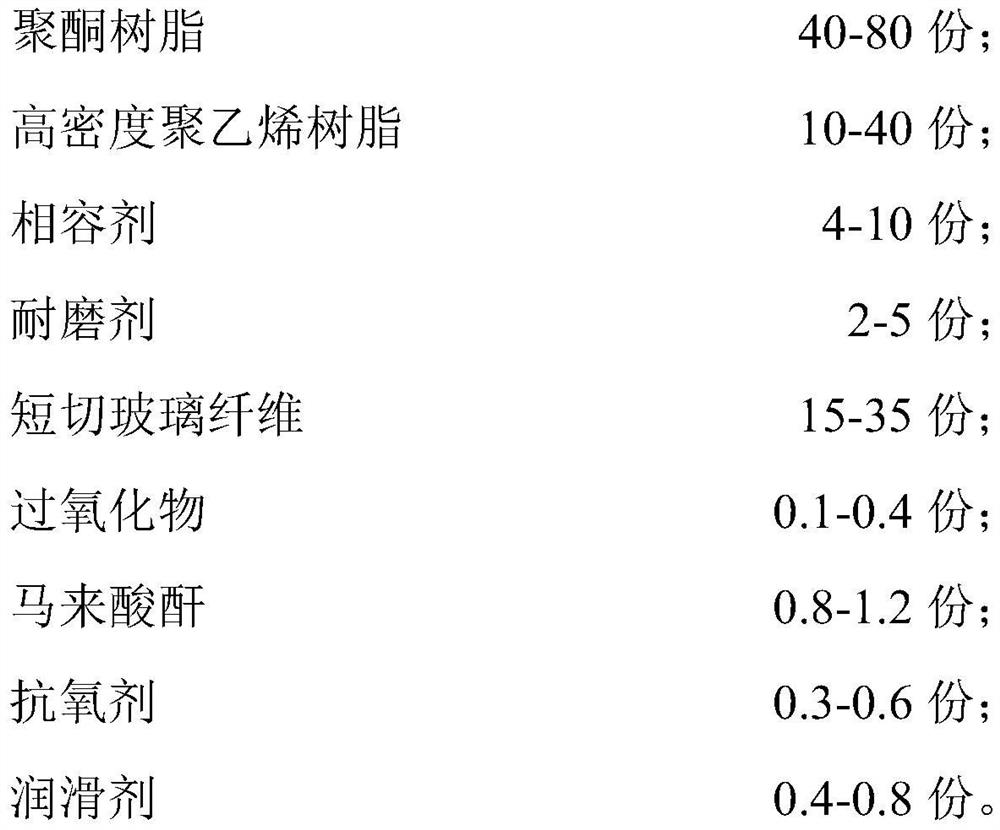

[0048] A high-impact and wear-resistant glass fiber reinforced POK-HDPE composite material, comprising:

[0049]

[0050] Put the above materials into the mixer and mix them evenly, then put the mixed materials into the main lower barrel of the extruder and granulate through the extruder. During the extrusion process, 27 parts of chopped glass fibers are fed through the side The temperature of each temperature zone of the extruder is 240°C in zone 1, 240°C in zone 2, 240°C in zone 3, 240°C in zone 4, 220°C in zone 5, 200°C in zone 6, and 200°C in zone 7. 200°C, 200°C in zone 8, 200°C in zone 9, 230°C at the head, and the screw speed of the extruder is 300rpm.

Embodiment 3

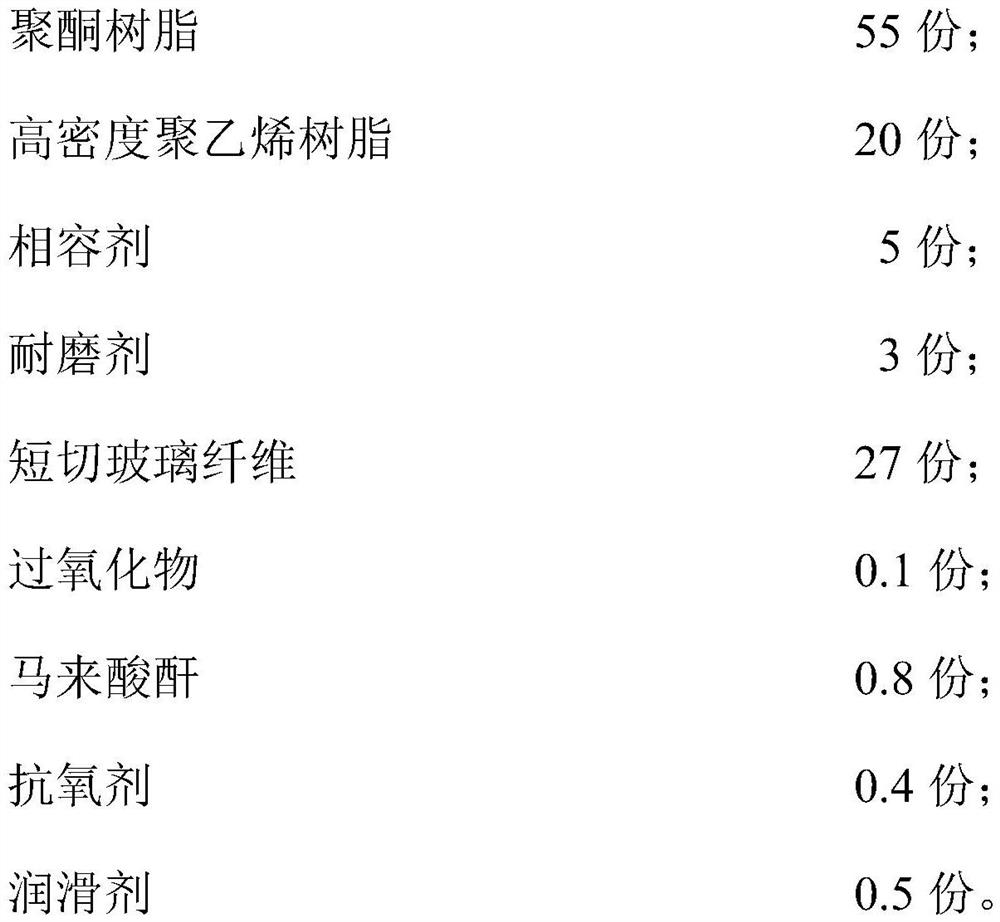

[0052] A high-impact and wear-resistant glass fiber reinforced POK-HDPE composite material, comprising:

[0053]

[0054]

[0055] Put the above materials into the mixer and mix them evenly, then put the mixed materials into the main lower barrel of the extruder and granulate through the extruder. During the extrusion process, 27 parts of chopped glass fibers are fed through the side The temperature of each temperature zone of the extruder is 240°C in zone 1, 240°C in zone 2, 240°C in zone 3, 240°C in zone 4, 220°C in zone 5, 200°C in zone 6, and 200°C in zone 7. 200°C, 200°C in zone 8, 200°C in zone 9, 230°C at the head, and the screw speed of the extruder is 300rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com