Ceramic product with antibacterial function and preparation method thereof

A technology of ceramic products and functions, applied in the field of ceramics, can solve the problems of poor antibacterial effect, wear of antibacterial layer, and inability to achieve antibacterial performance, and achieve the effects of reducing production costs, stable system, and good sterilization and disinfection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

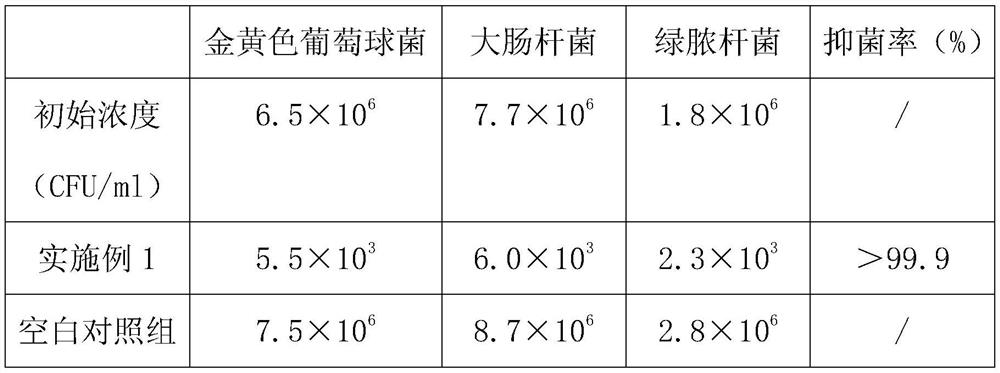

Embodiment 1

[0037] Embodiment 1: a kind of ceramic product with antibacterial function, described ceramic product is provided with antibacterial layer, glaze material layer and adobe brick layer successively from top to bottom, wherein, described antibacterial layer is polymer silver ion.

[0038] The glaze layer is made up of the following raw materials in parts by weight: 15 parts of high-purity potassium feldspar, 10 parts of albite, 13 parts of zirconium silicate, 5 parts of kaolin, 10 parts of barium carbonate, 4 parts of calcined zinc oxide, apatite 5 parts of limestone, 5 parts of calcined talc, 4 parts of α-alumina and 35.5 parts of water.

[0039] The polymer silver ion is a 1:1 ratio mixture of the hydroalcoholic polymer silver ion and the organic alcohol aqueous solution polymer silver ion.

[0040] The polymer silver ion in the step (3) and the glaze weight ratio in the step a are 1:186, and the firing temperature in the step (4) is 1160°C.

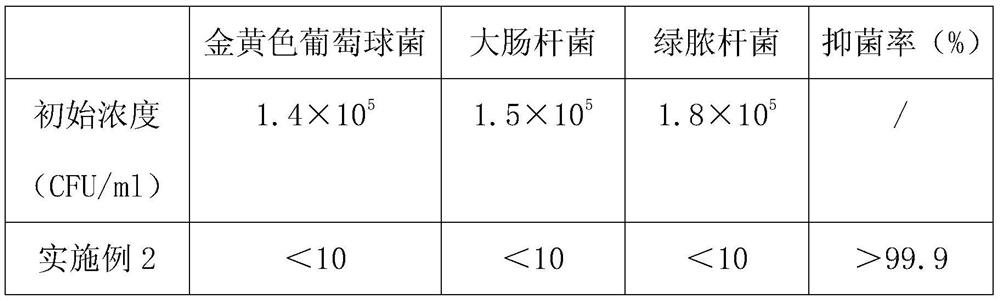

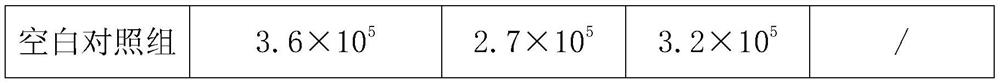

Embodiment 2

[0041] Embodiment 2: a kind of ceramic product with antibacterial function, described ceramic product is provided with antibacterial layer, glaze material layer and adobe brick layer successively from top to bottom, wherein, described antibacterial layer is polymer silver ion.

[0042] The glaze layer is made up of the following raw materials in parts by weight: 15 parts of high-purity potassium feldspar, 10 parts of albite, 13 parts of zirconium silicate, 5 parts of kaolin, 10 parts of barium carbonate, 4 parts of calcined zinc oxide, apatite 5 parts of limestone, 5 parts of calcined talc, 4 parts of α-alumina and 35.5 parts of water.

[0043] The polymer silver ion is a 1:1 ratio mixture of the hydroalcoholic polymer silver ion and the organic alcohol aqueous solution polymer silver ion.

[0044] The polymer silver ion in the step (3) and the glaze weight ratio in the step a are 1:355, and the firing temperature in the step (4) is 1160°C. .

[0045] Embodiment 1: a kind of...

Embodiment 4

[0049] Embodiment 4: a kind of ceramic product with antibacterial function, described ceramic product is provided with antibacterial layer, glaze material layer and adobe brick layer successively from top to bottom, wherein, described antibacterial layer is polymer silver ion.

[0050] The glaze layer is composed of the following raw materials in parts by weight: 15 parts of high-purity potassium feldspar, 20 parts of albite, 13 parts of zirconium silicate, 10 parts of kaolin, 10 parts of barium carbonate, 4 parts of calcined zinc oxide, phosphor ash 10 parts of stone, 5 parts of calcined talc, 8 parts of α-alumina and 35.5 parts of water.

[0051] The polymer silver ion is a 2:1 ratio mixture of the hydroalcoholic polymer silver ion and the organic alcohol aqueous solution polymer silver ion.

[0052] The weight ratio of the polymer silver ion in the step (3) to the glaze in the step a is 1:186; the firing temperature in the step (4) is 1250°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com